WIKI 30 VICKERS

AFFRI WIKI 30

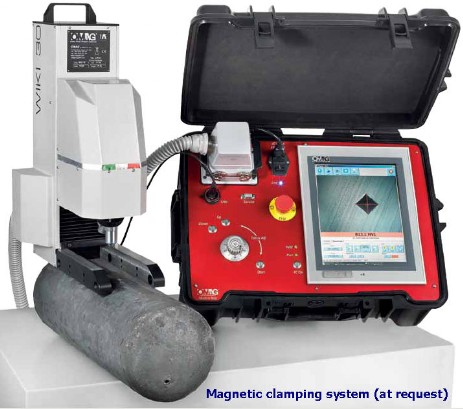

A new breakthrough in Vickers Hardness Testing. A Portable one instrument with a test load from 0.1 to 31.2 kgf. Eliminating the need to cut samples and perform tests in the Materials Laboratory, saving time, money and results accuracy.

Automatic instrument built for Vickers and Brinell hardness testing, simply attach onto tubes with a minimum diameter of 100mm and a maximum diameter of 700mm (by using the hook – chain system).

The instrument is portable and designed for being light and durable for harsh environments. The stand’s particular shape allows having both a plate supporting surface for testing samples with parallel sides, and a “V” plate for centering tubular samples.

Designed for housing a hook-chain system, the instrument allows to anchor it to large dimension tubes, thus giving precise tests under optimal stable conditions.

Automatic instrument built for Vickers and Brinell hardness testing, simply attach onto tubes with a minimum diameter of 100mm and a maximum diameter of 700mm (by using the hook – chain system).

The instrument is portable and designed for being light and durable for harsh environments. The stand’s particular shape allows having both a plate supporting surface for testing samples with parallel sides, and a “V” plate for centering tubular samples.

Designed for housing a hook-chain system, the instrument allows to anchor it to large dimension tubes, thus giving precise tests under optimal stable conditions.

This instrument special quality resides in it’s simplicity and user friendliness.

Wiki30 is fully automatic; thanks to it’s autofocus, once the measuring cycle is started, the instrument will perform the test, analyse the impression and display the hardness value, duly calculated, on the palmtop PC screen supplied with the instrument. The powerful analysis and impression optical recognition software (by Easydur System), allows for user friendly input for changing opertional parameters for,both testing and visual in order to allow valuable tests and perfect optical recognitions under any circumstances.

The software is equipped with on board statistics, data export and cataloguing of the testing parameters.

Standards : DIN EN ISO 6507 / DIN EN ISO 6506 / ISO 4545 / ASTM-E92 /ASTM-384 / JIS Z231

Operation : Automatic

Objective/Indenter : Turret Automatic Motorized

Microscope Objectives : 100x 200x 400x

Accuracy : +/- 0,5%

Auto-Reading measurements

Computer : Removable/ Tilt able Touch Screen

Software Operating System : Windows

Camera System : 2 MP

Measurement Resolution : 0.1 HV—0.1 HB

Head Stroke : 90 mm (motorized)

Focusing System : Auto-Motorized

X-Y table : 100 x 100 mm manual table

Stage Resolution : 0.001mm

Start :One start input to take contact with test surface, generate indentation and come back without interruption including auto focus

Portable hardness tester : Yes

Vibration source : Not affected

Program Console : User Friendly Icon Driven Program touch screen pen

Loading Mechanism : Incremental Load Cell Without Inertia no Friction no Vibration

Data Communication : USB

Weight : 38 kg

Power Supply : 110V-220V AC 50÷60 HZ

CE Conformance : Yes

Country of Origin : Made In Italy

Two Load range available :

WIKI 30A

1.961 - 2.942 - 4.905 - 9.81 - 19.61 - 29.4 – 49.05 - 61.3 - 98.1 - 147.1 - 153 - 196.1- 245.2 - 294.3 - 306.5 -409.5 N

0.3 - 0.5 - 1 - 2 - 3 - 5- 6.25 - 10 - 15 - 15.625 - 20 - 25 - 30 kgf (0.2 - 31.25 - 50 kgf on request)

WIKI 30B

0.098 - 0.196 – 0.245 - 0.294 - 0.49 - 0.981 - 1.962 - 2.942 - 4.905 - 9.81 - 19.62 - 29.43 - 49.05 - 98.1 N

(10gf - 20gf - 25gf - 30gf - 50gf - 100gf - 200gf - 300gf - 500gf - 1kgf - 2kgf - 3kgf - 5kgf - 10kgf)