Wireless Sensor Full Digital

Coatings & Industry > Physical properties > Thickness Dry Film

Digital signal processing

SmarTest: Intelligent Bluetooth sensor for coating thickness measurement

SmarTest is an intelligent wireless sensor for non-destructive coating thickness measurement and relays sensor data via Bluetooth to your tablet, smart phone or to the coating thickness gauge MiniTest 745.

The radio sensor SmarTest is 16 mm in diameter and 125 mm in length somewhat like a thick ballpoint pen and weighs just 48 g.

This means that you can carry the SmarTest with you anywhere.

The standard scope of supply comes with the F 2.6 or FN 2.6 sensor, which has been specially optimised for measuring on thin auto body sheets and can be used for a sheet thickness downwards of 0.3 mm.

You can connect any SIDSP sensor to SmarTest and cover a wide range of coating thickness measurement tasks.

Operation

It is very simple to operate the SmarTest:

•Start the SmarTest app on the mobile device

•Switch on the wireless sensor and the Bluetooth connection is established automatically

•Take measurements

The SmarTest app helps you through all steps with context-sensitive help texts in 4 languages currently.

Control / Data Transfer

Sensor control and data transfer of the measuring values is done via Bluetooth 4.0 / Bluetooth Smart (low energy). The sensor and mobile device can be placed about 10 m away from each other, even farther under good transmission conditions.

Measuring range F 2.6: F: 0 ... 2.6 mm

FN 2.6: F: 0 ... 2.6 mm

N: 0 ... 1.3 mm

Measuring method F:Magnetic induction

N: 0 ... 1.3 mm

Measuring method F:Magnetic induction

N:Eddy current

Accuracy ± (1 µm + 0.75% of reading)

Repeatability ± (0.5 µm + 0.5% of reading)

Low range resolution 0.05 µm

Minimum curvature radius convex: 1.5 mm

Accuracy ± (1 µm + 0.75% of reading)

Repeatability ± (0.5 µm + 0.5% of reading)

Low range resolution 0.05 µm

Minimum curvature radius convex: 1.5 mm

concave:7.5 mm

Minimum measuring area Ø 5 mm

Minimum substrate thickness F:0.3 mm

Minimum measuring area Ø 5 mm

Minimum substrate thickness F:0.3 mm

N:40 µm

Recommanded probes

Ref. Description Range

10080-135-0200 FN 1.5 0...1500 µm (F)

0...700 µm (N)

10080-135-0000 F 1.5 0...1500 µm

10080-135-0100 N 0.7 0...700 µm

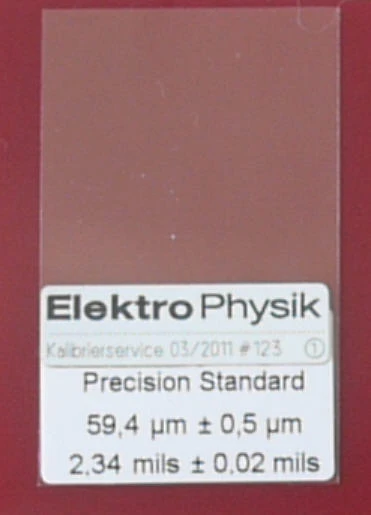

Calibration foils

Calibration foils with thicknesses ranging from 10 μm up to 8 mm

Option: Manufacturer’s certificates M according to DIN 55350 part 18 proving the accuracy of calibration foils and/or gauge