Magneto static principle

Coatings & Industry > Material properties > Material Thickness

MiniTest 7200 FH/MiniTest 7400 FH

Working on the magneto-static principle, the gauges enable quick and easy measurement on non-ferromagnetic materials.

The measuring system consists of a handy sensor, which is connected via a cable to the base and display unit for visualization and processing of readings.

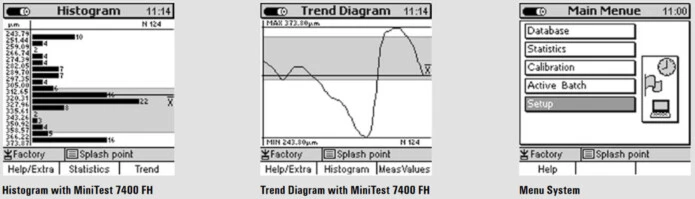

For measurement, specially treated target balls made of a ferromagnetic material are used as a reference.

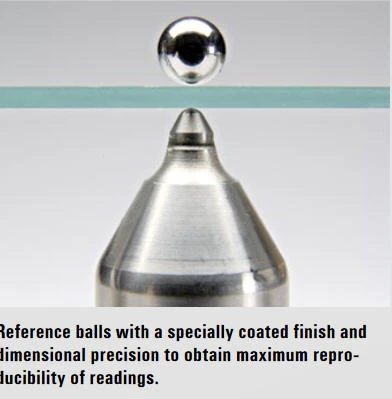

For measurement, a target ball is placed on the material to be measured so that the material thickness between target ball and sensor will be measured.

The measuring system comes with sensor stand (available as an option) to add additional comfort of handling during measurement

High-precision Wall Thickness Measurement

• Of non-ferrous materials

• Up to 24 mm thickness

• For packaging materials such as bottles, glass or plastics containers

• For composite materials, aluminium or titanium parts of complex shapes in the aviation or automotive industry

• Menu-guided user interface

• Context-oriented online help

• SPC

• Extremely accurate through digital signal processing

Two Models

MiniTest 7200 FH

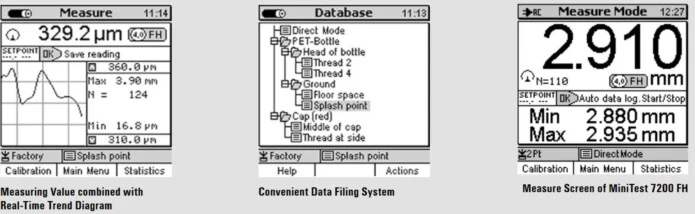

offers measurement capabilities including real-time thickness measurement, display of minimum and maximum readings, an offset mode, and automatic storage of up to 100,000 values.

MiniTest 7400 FH

offers the same capabilities as the MiniTest 7200FH plus statistical graphing, real time trend, data base with up to 200 batches and a larger memory for automatic storage of up to 240,000 readings, e. g. 1,200 readings per batch.

SIDSP ®

Provides Higher Accuracy The MiniTest 7200 FH/MiniTest 7400 FH Gauging Systems incorporate sensor-integrated digital signal processing (SIDSP®). All measuring signals are digitally created and completely digitally processed inside the sensor itself. Only completely processed digital readings are transferred to the base unit for display, statistical analysis, and storage.

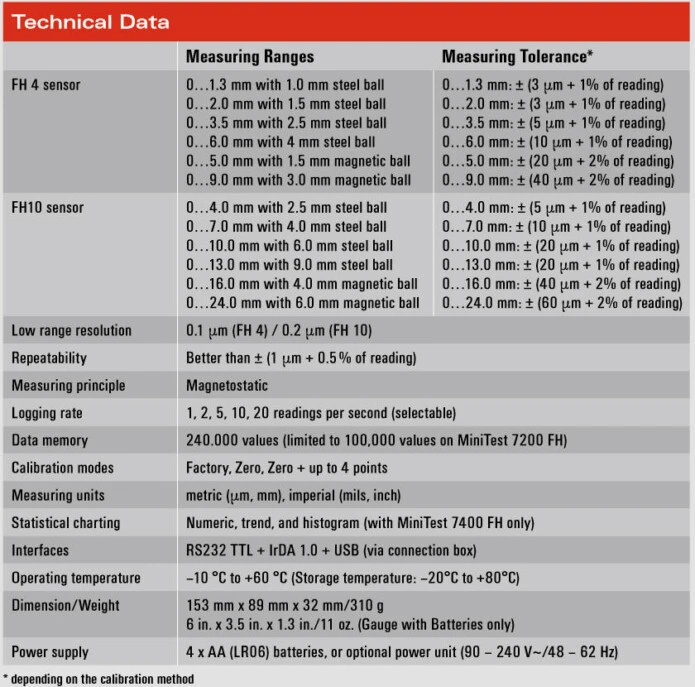

Two Sensors to Choose From In order to maximize the accuracy of readings, two easily interchangeable sensors with a hardened tip and a variety of ball sizes are available to cover the various thickness ranges.

- The FH 4 sensor uses steel balls to measure from 0 to 6 mm and magnetic balls to measure up to 9 mm.

- The FH 10 sensor uses steel balls to measure from 0 to 13 mm and magnetic balls to measure up to 24 mm.

The two sensor models are interchangeable and can be connected to any of the two gauge models.

Product Features at a Glance

- Wear-resistant carbide sensor tip High precision target balls for reproducible measurements

- Data capture up to 20 data points per second

- Sensor-integrated digital signal processing

- Multi-point calibration up to 5 points

- Large, easy-to-read display

- Display of minimum and maximum

- Menu-controlled user interface

- Context-sensitive online help

- SPC capabilities