142-40 Basic

Metal Testing > Sheet Metal Testing > Model 142

142-40 Basic Universal-Sheet Metal Testing Machine

Universal sheet metal testing machine, Erichsen cupping and deep-draw testing and FLC, up to 200 kN tensile force

The Universal Sheet Metal Testing Machine Model 142-40-Basic with electro-hydraulic drive, fully automatic test sequence and switch off at specimen failure, max. drawing force of 400 kN.

Application:

This Testing Machine can be used not only to perform effortlessly, quickly and accurately all important and known deep drawing tests for ferrous and non-ferrous metals, but it is also designed for a large number of additional technological investigations like the ERICHSEN Cupping Test and the ERICHSEN Deep Drawing Cup Test on sheet and strips.

Order number: 101-02890331

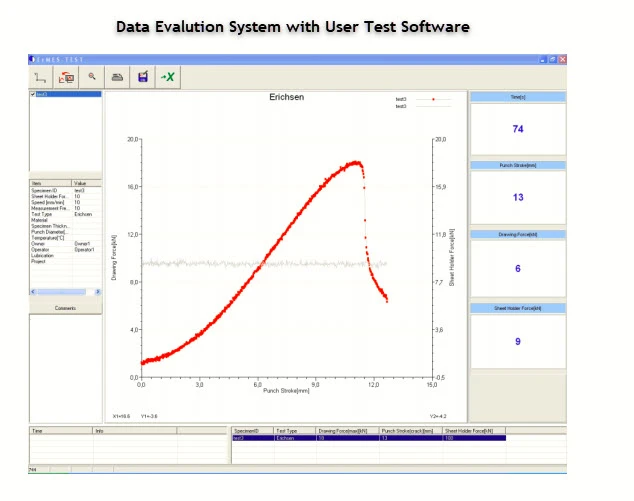

ErMES

Data logger for recording the measurements such as drawing force, blank holder force and stroke; the connection is made by an USB connection.

The software included in the scope of supply runs under WIN VISTA, 7, 8 and 10.

The scope of supply includes PC, VDU and printer.