Adhesion

Coatings & Industry > Mechanical properties > Adhesion & Elongation

Test Principle Cross-Cut Test

There are two methods to measure the resistance of coating to separation from substrates : the first by producing a X-cut (Test Method A) or the second one by producing a right angle lattice patern on the sample (Test Method B).

The basic principle is to cut through the coating with a series of several cuts at right angles in a defined manner.

There are two methods to measure the resistance of coating to separation from substrates : the first by producing a X-cut (Test Method A) or the second one by producing a right angle lattice patern on the sample (Test Method B).

The basic principle is to cut through the coating with a series of several cuts at right angles in a defined manner.

The square pattern that is obtained can be evaluated visually by examining the way in which the coating has broken away from the base material (along the cutting edges and/or complete squares), and this can be compared with schematic representations in the standard.

To perform that test you will need a roll of test tape, you can choose for an Astm one or an ISO.

The result will be furnished with a judgement scale’s code (e.g. with the aid of the evaluation table in accordance with EN ISO 2409).

To perform that test you will need a roll of test tape, you can choose for an Astm one or an ISO.

The result will be furnished with a judgement scale’s code (e.g. with the aid of the evaluation table in accordance with EN ISO 2409).

GUIDED TESTING. SINCE 1910.

Erichsen the world’s leading manufacturer of , well-known and proven testing machines and instruments for the coatings industry , introduces the essential analytical tool to any laboratory manager.

Never waste time discussing, challenging and controlling your grid test.

Ensure the tranquility and ease of professional archiving only available with the 295/XVII

295/XVI Automatic Cross Hatch Cut Rating System CrossScan

Purpose and Application

The cross-cut test is the oldest test method established worldwide for evaluating the adhesive strength of coating materials on substrates lying underneath, still has nothing lost of its popularity and validity and continues to be present across all industries, and even nearly ubiquitous.

The evaluation of the test results according to valid standards, i.e. their assignment according to the corresponding characteristic values, has been carried out almost 100% visually for decades by comparison with an example table.

Here is an area loss of coating material to be evaluated in the cutting grid, rich in contrast in of an exemplary graduated form.

The ISO 2409 as well as standards with the same reference values for evaluation are to be mentioned here above all.

However, a cross-cut pattern in which there has been material loss is similar to a cross-cut pattern with the same reference values characteristic (!) of no other to 100%, since this refers only to the percentage material loss per area.

A user is also required to be able to make an abstract assignment when making a visual comparison.

And here it becomes potentially uncomfortable for the visual evaluator, because corresponding talents as well as also exercise and experience can be individually very different and any visual definition made of characteristic values by which the user can be influenced accordingly.

Especially in border areas, where the just reached (or maybe not yet completely reached) value can be influenced by the user (characteristic value

achieved?) if applicable, decisive on compliance with a required delivery specification, or validity of an expensive complaint, it is conceivable that the users concerned will be psychologically burdened, since of course the protection of one's own interests can also play a role; a good example for the danger, if necessary.

The threat of user dependency, or at least the probability that it cannot be ruled out across the board.

The Automatic Cross Hatch Cut Rating System CrossScan 295/XVI closes the user dependency from the valuation transaction.

Cross Hatch Cutter 295

Order number: 101-0019.01.31

"REFERENCE CLASS"

6 edges, cutting distance 1 mm, incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

6 edges, cutting distance 1 mm, incl. magnifying glass, polyamide bristle brush and plastic case

Cross Hatch Cutter 295

Order number: 101-0019.02.31

"REFERENCE CLASS"

6 edges, cutting distance 2 mm, incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

6 edges, cutting distance 2 mm, incl. magnifying glass, polyamide bristle brush and plastic case

Cross Hatch Cutter 295

Order number: 101-0019.07.31

"REFERENCE CLASS"

6 edges, cutting distance 3 mm, for Grid Cutting Tests acc. to EN ISO, ISO, JIS and VDA,

incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

6 edges, cutting distance 3 mm, for Grid Cutting Tests acc. to EN ISO, ISO, JIS and VDA,

incl. magnifying glass, polyamide bristle brush and plastic case

Cross Hatch Cutter 295

Order number: 101-0019.09.31

"REFERENCE CLASS"

With free turnable axle between hand grip and cutting head, 6 edges, cutting distance 1 mm,

for Grid Cutting Tests acc. to EN ISO, ISO, VDA and EN, incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

With free turnable axle between hand grip and cutting head, 6 edges, cutting distance 1 mm,

for Grid Cutting Tests acc. to EN ISO, ISO, VDA and EN, incl. magnifying glass, polyamide bristle brush and plastic case

Cross Hatch Cutter 295

Order number: 101-0019.10.31

"REFERENCE CLASS"

With free turnable axle between hand grip and cutting head, 6 edges, cutting distance 2 mm,

for Grid Cutting Tests acc. to EN ISO, ISO, ASTM, JIS, and VDA, incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

With free turnable axle between hand grip and cutting head, 6 edges, cutting distance 2 mm,

for Grid Cutting Tests acc. to EN ISO, ISO, ASTM, JIS, and VDA, incl. magnifying glass, polyamide bristle brush and plastic case

Cross Hatch Cutter 295

Order number: 101-0019.11.31

"REFERENCE CLASS"

With free turnable axle between hand grip and cutting head, 6 edges, cutting distance 3 mm,

for Grid Cutting Tests acc. to EN ISO, ISO, JIS and ASTM, incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

With free turnable axle between hand grip and cutting head, 6 edges, cutting distance 3 mm,

for Grid Cutting Tests acc. to EN ISO, ISO, JIS and ASTM, incl. magnifying glass, polyamide bristle brush and plastic case

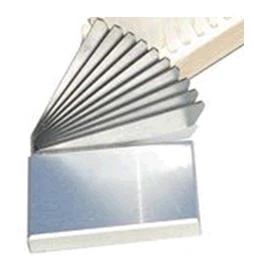

Cross Hatch Cutter 295

Order number: 101-0019.03.31

"REFERENCE CLASS"

With 10 swivel-mounted folding ruler of 1 mm thickness each, for Grid Cutting Tests acc. to EN ISO, ISO, ASTM, JIS, BS, NF, SNV, EN and VDA, incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

With 10 swivel-mounted folding ruler of 1 mm thickness each, for Grid Cutting Tests acc. to EN ISO, ISO, ASTM, JIS, BS, NF, SNV, EN and VDA, incl. magnifying glass, polyamide bristle brush and plastic case

Cross Hatch Cutter 295

Order number: 101-0019.12.31

"REFERENCE CLASS"

With 10 swivel-mounted folding rulers of 1 mm and 1.5 mm thickness each, for Grid Cutting Tests acc. to EN ISO, ISO, ASTM, JIS, BS, NF, SNV, EN, VDA and Daimler Benz (1.5 mm), incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

With 10 swivel-mounted folding rulers of 1 mm and 1.5 mm thickness each, for Grid Cutting Tests acc. to EN ISO, ISO, ASTM, JIS, BS, NF, SNV, EN, VDA and Daimler Benz (1.5 mm), incl. magnifying glass, polyamide bristle brush and plastic case

Cross Hatch Cutter 295

Order number: 101-0019.13.31

"REFERENCE CLASS"

Ergonomical optimized, triangular version with handle and 5 swivel-mounted folding rulers of 1 mm, 2 mm and 3 mm thickness each, for Grid Cutting Tests acc. to EN ISO, ISO, ASTM, JIS, BS, NF, SNV, EN and VDA, incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

Ergonomical optimized, triangular version with handle and 5 swivel-mounted folding rulers of 1 mm, 2 mm and 3 mm thickness each, for Grid Cutting Tests acc. to EN ISO, ISO, ASTM, JIS, BS, NF, SNV, EN and VDA, incl. magnifying glass, polyamide bristle brush and plastic case

Cross Hatch Cutter 295

Order number: 101-0019.15.31

Universal cross cut ruler, scaled cutting distances

(6 x 1 mm, 6 x 2 mm, 6 x 3 mm, 11 x 1 and 11 x 1,5 mm) adjusted by turning a thumb wheel

Universal cross cut ruler, scaled cutting distances

(6 x 1 mm, 6 x 2 mm, 6 x 3 mm, 11 x 1 and 11 x 1,5 mm) adjusted by turning a thumb wheel

Cross Hatch Cutter 295

Order number: 101-0019.05.31

"REFERENCE CLASS"

11 edges, cutting distance 1 mm, for Grid Cutting Tests acc. to ASTM and JIS, incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

11 edges, cutting distance 1 mm, for Grid Cutting Tests acc. to ASTM and JIS, incl. magnifying glass, polyamide bristle brush and plastic case

Cross Hatch Cutter 295

Order number: 101-0019.06.31

"REFERENCE CLASS"

11 edges, cutting distance 2 mm, for Grid Cutting Tests acc. to ISO, BS and NF, incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

11 edges, cutting distance 2 mm, for Grid Cutting Tests acc. to ISO, BS and NF, incl. magnifying glass, polyamide bristle brush and plastic case

Cross Hatch Cutter 295

Order number: 101-0019.04.31

"REFERENCE CLASS"

2 edges, cutting distance 5 mm, for Grid Cutting Tests acc. to EN (formerly ECCA), incl. magnifying glass, polyamide bristle brush and plastic case, for all coil coatings

"REFERENCE CLASS"

2 edges, cutting distance 5 mm, for Grid Cutting Tests acc. to EN (formerly ECCA), incl. magnifying glass, polyamide bristle brush and plastic case, for all coil coatings

Cross Hatch Cutter 295

Order number: 101-0019.14.31

hard-coated test tip mounted into an adapter block with holder, for cuts on curved

surfaces, incl. flexible ruler and plastic case, without Manufacturer’s Test Certificate M

hard-coated test tip mounted into an adapter block with holder, for cuts on curved

surfaces, incl. flexible ruler and plastic case, without Manufacturer’s Test Certificate M

Cross Hatch Cutter 295

Order number: 101-0239.01.31

6 edges, cutting distance 1 mm, without Manufacturer’s Test Certificate M

6 edges, cutting distance 1 mm, without Manufacturer’s Test Certificate M

Cross Hatch Cutter 295

Order number: 101-0239.02.31

6 edges, cutting distance 2 mm, without Manufacturer’s Test Certificate M

6 edges, cutting distance 2 mm, without Manufacturer’s Test Certificate M

Cross Hatch Cutter 295

Order number: 101-0239.05.31

11 edges, cutting distance 1 mm, incl. tubular plastic case, without Manufacturer’s Test Certificate M.

11 edges, cutting distance 1 mm, incl. tubular plastic case, without Manufacturer’s Test Certificate M.

Cross Hatch Cutter 295

Order number: 101-0239.06.31

egonomically optimized, triangular version as supplied with model 295/XIII, with 5 swivel-mounted folding rulers of 1 mm, 2 mm and 3 mm thickness each,

without Manufacturer’s Test Certificate M

egonomically optimized, triangular version as supplied with model 295/XIII, with 5 swivel-mounted folding rulers of 1 mm, 2 mm and 3 mm thickness each,

without Manufacturer’s Test Certificate M

Cross Hatch Cutter 295

Order number: 101-0239.07.31

with 10 swivel-mounted folding rulers of 1 mm thickness each as supplied with model 295/III, without Manufacturer's Test Certificate M

with 10 swivel-mounted folding rulers of 1 mm thickness each as supplied with model 295/III, without Manufacturer's Test Certificate M

Cross Hatch Cutter 295

order number: 101-0239.08.31

with 10 swivel-mounted folding rulers of 1 mm and 1.5 mm thickness each as supplied with model 295/XII, without Manufacturer's Test Certificate M

with 10 swivel-mounted folding rulers of 1 mm and 1.5 mm thickness each as supplied with model 295/XII, without Manufacturer's Test Certificate M

Ref 110-1542ADAST

For Cross Cut Adhesion Test : adhesive tape sold by 2 rolls.

This tape is used for assessing the adhesion of coating films to metallic substrates by applying and removing pressure-sensitive tape over cuts made in the film.

To perform test according astm d3359 : test method A (x-cut)and test method B (a lattice pattern with either six or eleven cuts in each direction) l

This adhesif replace the discontinued Permacel P-99.

For Cross Cut Adhesion Test : adhesive tape sold by 2 rolls.

This tape is used for assessing the adhesion of coating films to metallic substrates by applying and removing pressure-sensitive tape over cuts made in the film.

To perform test according astm d3359 : test method A (x-cut)and test method B (a lattice pattern with either six or eleven cuts in each direction) l

This adhesif replace the discontinued Permacel P-99.

Cross Hatch Cutter 295

Ref : Ref : 215-8705B

For Cross Cut Adhesion Test : adhesive tape sold by 2 rolls. Lenght : 66 m x 25 mm

This tape is used for assessing the adhesion of coating films to metallic substrates by applying and removing pressure-sensitive tape over cuts made in the film.

This adhesive tape having adhesiveness between 6 N per 25 mm width and 10 N per 25 mm width (measured in accordance with IEC 60454-2) must be used to perform the ISO cross cut.

Lenght : 66 m x 25 mm

50 mm widht tape available on request.

Picture only for illustration

For Cross Cut Adhesion Test : adhesive tape sold by 2 rolls. Lenght : 66 m x 25 mm

This tape is used for assessing the adhesion of coating films to metallic substrates by applying and removing pressure-sensitive tape over cuts made in the film.

This adhesive tape having adhesiveness between 6 N per 25 mm width and 10 N per 25 mm width (measured in accordance with IEC 60454-2) must be used to perform the ISO cross cut.

Lenght : 66 m x 25 mm

50 mm widht tape available on request.

Picture only for illustration

Limited availability

Cross Hatch Cutter 295

Ref : 215-8705B6

For Cross Cut Adhesion Test : adhesive tape sold by 6 rolls. Lenght : 66 m x 25 mm

This tape is used for assessing the adhesion of coating films to metallic substrates by applying and removing pressure-sensitive tape over cuts made in the film.

This adhesive tape having adhesiveness between 6 N per 25 mm width

and 10 N per 25 mm width (measured in accordance with IEC 60454-2) must be used to perform the ISO cross cut. Lenght : 66 m x 25 mm

50 mm widht tape available on request.

Picture only for illustration

For Cross Cut Adhesion Test : adhesive tape sold by 6 rolls. Lenght : 66 m x 25 mm

This tape is used for assessing the adhesion of coating films to metallic substrates by applying and removing pressure-sensitive tape over cuts made in the film.

This adhesive tape having adhesiveness between 6 N per 25 mm width

and 10 N per 25 mm width (measured in accordance with IEC 60454-2) must be used to perform the ISO cross cut. Lenght : 66 m x 25 mm

50 mm widht tape available on request.

Picture only for illustration

Cross Hatch Cutter 295

Order number: 101-03230131

Automatic Cross Hatch Cut Rating System CrossScan 295/XVI

Included in the scope of supply:

Hardware, Software, USB cable and Manual.

Automatic Cross Hatch Cut Rating System CrossScan 295/XVI

Included in the scope of supply:

Hardware, Software, USB cable and Manual.