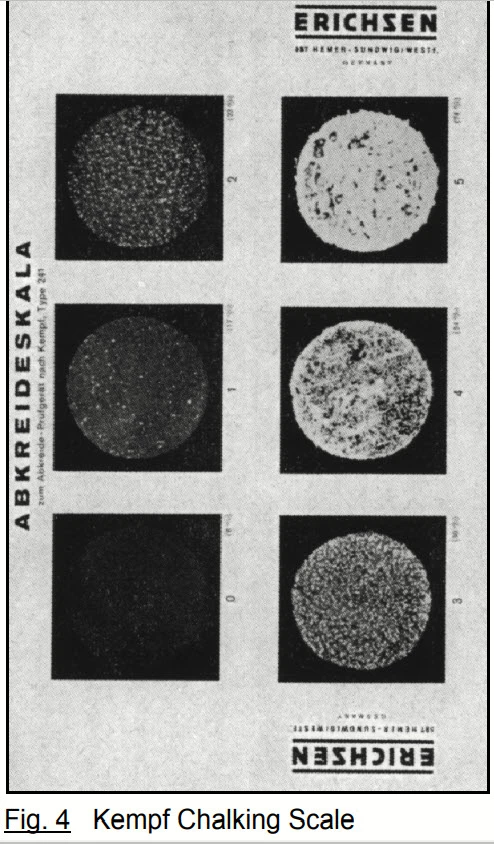

Chalking acc. to Kempf

Coatings & Industry > Brightness GLoss & Chalking

Chalking Rate Tester : For quick determination of the chalking rate of coating materials

Chalking Rate Tester according to Kempf Model 241

The Model 241 chalking rate tester consists of a light-metal cylinder.

At the end of this cylinder is a 40-mm diameter rubber stamp and a Shore A hardness of 60 ±5.

The built-in compression spring enables a stamping pressure of 50 to 250 N.

The ring marks punched into the stamp shaft, stepped at intervals of 50 N, also allow the load to be less than the standard 250 N pressing force.

Pressing by hand is too unpredictable to ensure a consistent load from the rubber stamp on the test surface.

Therefore, we recommend using a special stand.

The lever is used to apply the contact pressure more easily and precisely.

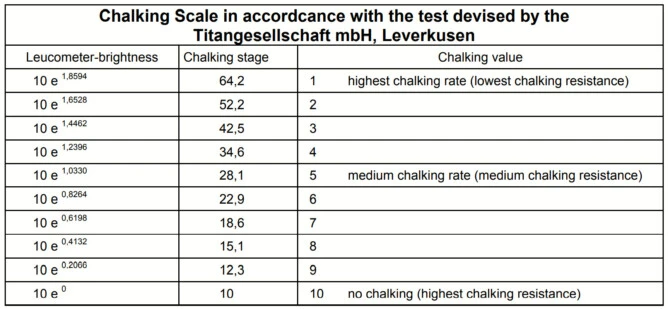

DIN 53 159 Titangesellschaft mbH (Kronos Titan GmbH)

Test procedure

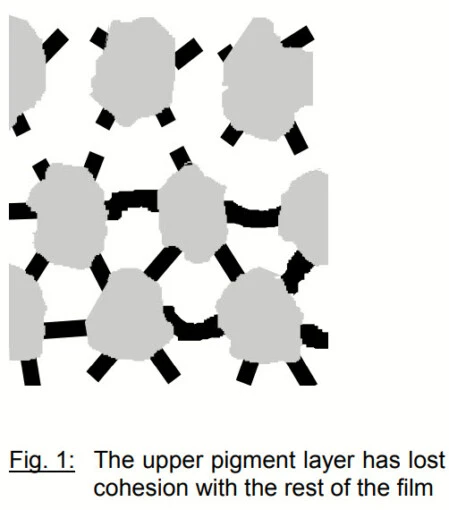

The photographic paper is soaked in water at room temperature for four minutes.

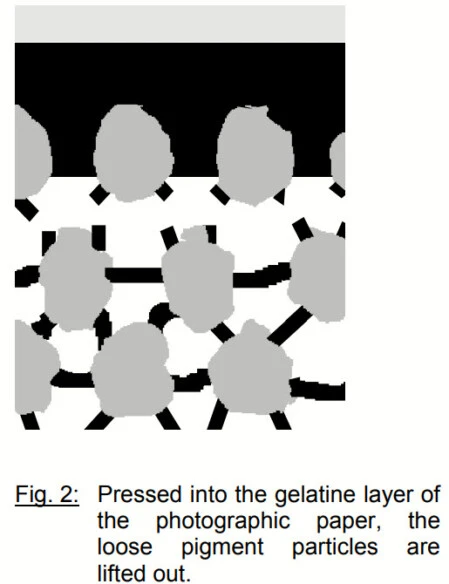

After removing any water adhering to the surface with filter paper, it is laid upon the paint to be tested, gelatine face down.

Placing the rubber stamp on the reverse side of the paper, the Chalking Tester is pressed down as vertically as possible with the ball of the thumb - or with the lever when using the stand - with a pressure of 25 kg (55 lbs) until the ring mark 250 is reached After lifting the stamp the photographic paper is pulled off and dried.

Notes:

Load:

In special cases - to be agreed upon - a smaller load may be used.

Duration:

The duration of pressure does not influence the test result.

Photographic paper:

In order to avoid measuring errors it is recommended to obtain the same quality of paper from the same supplier.

Dirty coatings:

Surface contamination of paints that have undergone weathering in the open air may simulate chalking of the paint on impressions of unexposed fixed (therefore white) photographic paper, although only the soiled layer has been lifted off the paint surface.

To be able to discern in such cases between contamination and chalking it is advisable to make the impressions on white as well as on black photographic pape