Erichsen 430 P

Coatings & Industry > Mechanical properties > Adhesion & Elongation

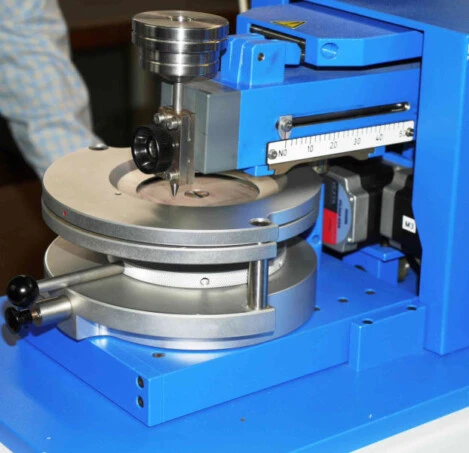

SCRATCH HARDNESS TESTER 430 P-Smart

- Scratch Hardness

- Cross Hatch Cut

- Scratch Resistance

- Writing Effect

Programmable Logic Control (PLC)

Optionally with manually actuated/motor-drivenloading force and manually actuated/automatic test panel turn

Operation, documentation and data management via ERICHSEN-App

- DIN EN ISO 2409

- ASTM D 3359

- JIS K 5600-5-6

- SNV 37 111

- VDA 621-411

- ECCA T6

- GME 60 280

Design and Function

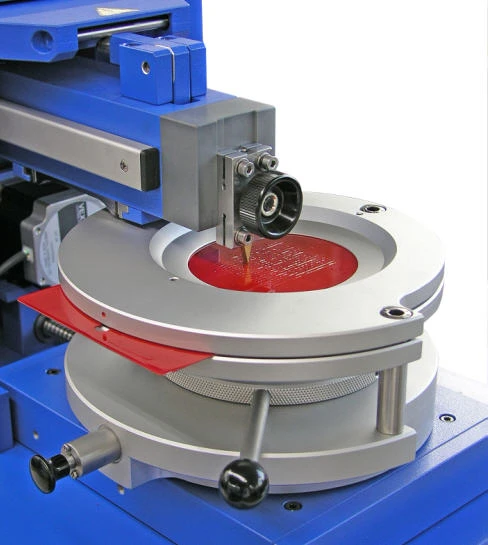

The SCRATCH HARDNESS TESTER 430 PSmart is a benchtop instrument of sound mechanical construction which provides reliable, well-defined cuts, even under extreme test

conditions.

By default, the machine is equipped with a protective cover.

The device is operated via touch panel (automatic menu navigation).

The test procedure is carried out automatically and all parameters (cutting speed, cutting stroke, crosscut pattern) can be set using the keyboard.

Each motion sequence (transport of test panel, cut positioning and any required pressure adjustment) is driven by a separate step motor.

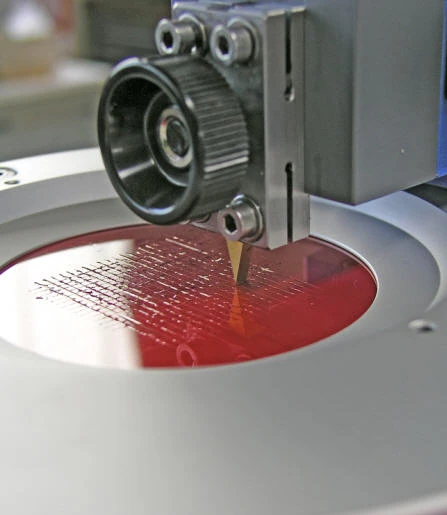

During the test the specimen is conveyed linearly and at a constant speed under the test tip which has been set at the required pressure load (max. 40 N).

A transmission guide ensures that the test tip is lowered onto the test panel as defined.

The scope of supply includes two control plates for different cross-cut patterns which can be easily interchanged.

With Model 430 P-Smart parallel cross hatch cuts with graduated test forces are possible.

After carrying out the first cross hatch cut the instrument can be stopped and the test force (up to 50 N) can be ad-justed individually before starting the next test track.

Theoretically, 80 test tracks with a distance of 0.5 mm of different test forces are possible within the pre-selected cross hatch cut programme.

The SCRATCH HARDNESS TESTER 430 PSmart is power-driven and obtainable in four versions - with manual or with motor-driven force regulation and with manual or motor-driven test panel turn. On the manual version it is a simple matter to adjust the test force to the exact pressure.

The instrument with motor-driven force regulation provides the additional benefit of conducting a trial run with gradually increasing force.

In this way, the force required to achieve a through cut can be automatically ascertained in the course of a "trial cut".

A 6-piece weight set is available as an optional accessory for conducting special tests in the lower pressure range and enables cuts with test forces in the range (1 - 15) N - graduated in 1-N steps.

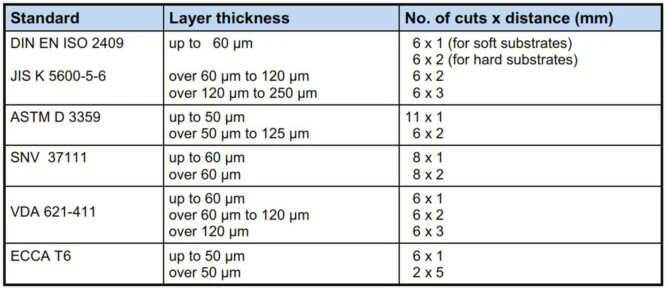

Cross Hatch Testing

The SCRATCH HARDNESS TESTER 430 P-Smart enables cross hatch tests to be conducted in accordance with all the usual standards, summarized in the following table, and carried out immediately without additional programming.

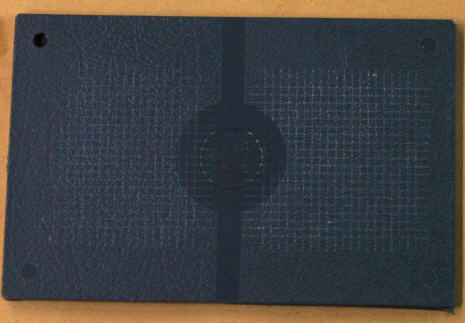

The following cross-cuts can be selected by pressing a key (number of cuts x distance in mm between cuts) 2 x 5, 6 x 1, 6 x 2, 6 x 3, 8 x 1, 8 x 2, 11 x 1.

The cuts are carried out automatically in succession using the test tip for cross hatch at a cutting speed of 40 mm/s.

After turning the test panel manually by 90°, the procedure is repeated to complete the cross-cut pattern.

The load required to ensure that the layer of varnish will be cut through to the substrate must be ascertained in trial runs.

With Model 430 P-II-Smart or Model 430 P-IV-Smart (motor-driven force adjustment) this can be carried out very simply by performing a "trial cut".

For the examination of cross hatch cuts a magnifiying glass with 2.5 magnification is included in the scope of supply.

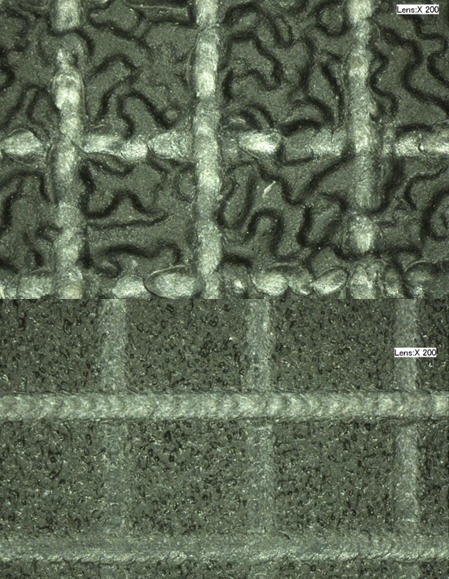

To evaluate the cross hatch pattern achieved, it is visually related to a comparison pattern within a scheme indicated in the relevant standard (cross cut classification).

In ECCA T6 it is mentioned that the cross hatch cut test may be intensified by a subsequent cupping test according to DIN EN ISO 1520.

For this purpose we recommend the ERICHSEN Lacquer and Paint Testing Machines, models 200 and 202 EM.

Although the results of adhesion tests in accordance with the cross hatch method are comparable with each other, they are - due to their respective procedures - not transferable to results of alternative test methods (e. g. perpendicular pull-off test according to DIN EN ISO 4624).

The ERICHSEN production programme offers the following model for adhesion testing to the pull-off method:

- Adhesion Test Apparatus, Model 525 (manual / inexpensive)

Technical Data

Dimensions (W x H x D) : 725 x 560 x 425 mm

Net weight approx. 50 kg

Power supply : 230 VAC / 50 Hz

Consumption : ca, 100W-150W

Test panel format min. : 80 x 50 mm

Test panel format max. : 165 mm wide, any length

Thickness of specimen : 0.5 - 20 mm

Standard load range2) : 2 - 50 N (2-N grading)

Special load range : 1 - 15 N (1-N grading)

Cutting path : 25 or 40 mm

Cutting speed : 1 m/min or 40 mm/s

Cutting path : 25 or 40 mm

Cutting speed : 1 m/min or 40 mm/s

2) Optional set of weights for bottom load range