MiniTest 725-735-745

Coating thickness gauge

MiniTest 700

SIDSP®-Technology

Minitest 70 F & 70 FN

SIDSP®-Technology

Performance features

Dual sensor for automatic identification of the substrate (FN model). According to the substrate, it adjusts to the appropriate measuring principle: magnetic induction or eddy currents principle.

Quick statistics mode to calculate the number of readings, average, standard deviation and min., max. value lightweight: 80 grams only

Measuring range N: 0 mm - 2.5 mm/ 100 mils

F: 0 mm - 3 mm/ 120 mils

Measuring principle magnetic-induction/eddy currents

Signal processing Sensor integrated 32-bit signal

processing (SIDSP®)

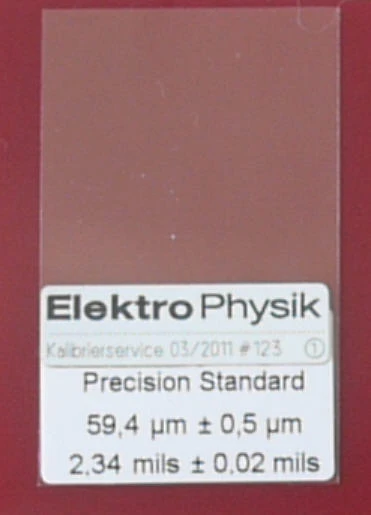

Accuracy (according to DIN 55350 Part 13) ± (1.5 μm + 3% of reading) with

1-point calibration

± (1.5 μm + 2% of reading) with

2-points calibration

Repeatability (according to DIN 55350 Part 13) ± (1 μm + 1% of reading)

Low range resolution 0.5 µm

Minimum curvature radius convex 5 mm

Minimum curvature radius concave 40 mm

Minimum substrate thickness F: 0.5 mm N: 0.04 mm