Centrifugal Film Applicator

Coatings & Industry > Physical properties > Film Applicators & Filmographs

Centrifugal Film Applicator Model 334

Purpose and Application

The Centrifugal Film Applicator, Model 334 applies coatings of even thickness on specimen panels with a length of side from 80 to 200 mm, for test purposes.

The advantages of this method of application are economical (saving in time) and in the unequalled accuracy and reproducibility.

The equipment is particularly of interest where a high level of consistency in film thickness or extremely thin coating layers are required.

Design and Function

The Centrifugal Film Applicator, Model 334 is a bench mounted instrument, consisting of a sheet metal housing, operator’s control panel, specimen holder with collecting trough and protective hood.

The speed and the application time are continuously variable between 100 - 2,000 min-1 and 5 - 300 s.

The selected speed is shown on a display instrument.

At the end of the preset centrifugation time the applicator switches off automatically and the specimen can be taken out of the holder.

For reasons of safety, the protective hood cannot be lifted to remove the specimen until the rotating specimen holder has come to a complete standstill.

The specimen holder and the collecting trough are removable for easy cleaning.

Application Method

The specimen panel to be coated is centred and positioned with 4 locating screws.

With fragile specimens, e.g. of thin glass, it is advisable to use the glass plate attachment, which is available as an accessory.

This is also generally suitable for specimen thicknesses between 1 mm and 3 mm. Thanks to the fixed centring feature which is set to the specimen format it is particularly time-saving when applying series coatings.

An adequate quantity of coating material (5 - 10 g) is poured onto the centre of the specimen, which is then made to rotate at a preset speed, and for a selected period of time.

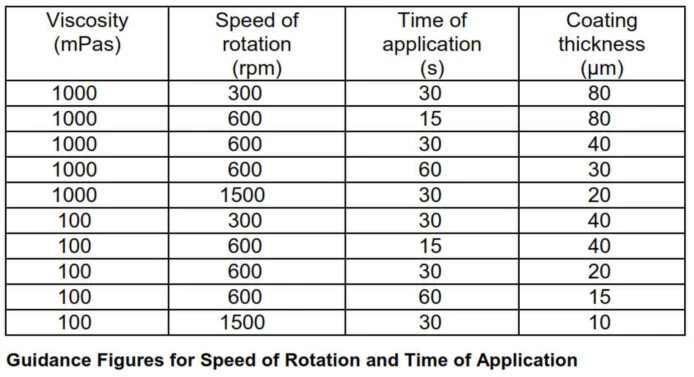

Optimum application conditions depend on the viscosity, or more accurately on the flow properties, density and solid content of the coating material.

Approximate values are shown in the chart.

The centrifugal force acting on the coating material causes this to be spread evenly across the specimen panel. Surplus coating material is thrown off the edge and collected in the surrounding trough. The coating applied in this way does not vary with distance from the centre of rotation, i.e. it is even over the entire area.

Only in the case of thixotrope paints is there a possibility that the film thickness will vary, tapering to greater thickness towards the middle.