Lab oven

Laboratory Product > Heating

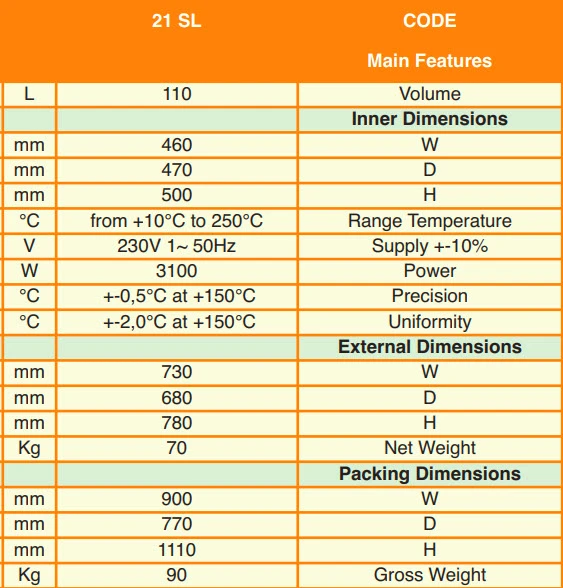

21SL Safety Drying Ovens Galli’s Original Equipments

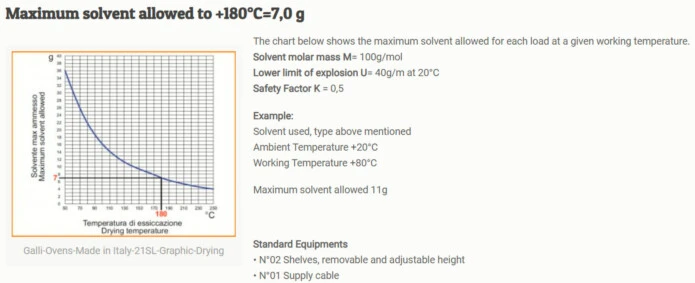

21SL Safety-Paint Drying Ovens by Galli for chemical industry and research.

Suitable for coil coating test procedures, glues, adhesives, organic solvents and safety tests.

PLUS

• AG-System Control: PID Digital Microprocessor, careful and sensitive. Version: DAILY, PRO, TALENT• Range Temperature: from +10,0°C above ambient up to+250°C• Safety Device, Class 3.1• Suitable for dry samples containing solvents• According to EN 1539• Reproducibility of the tests: in applications where avoiding the formation of explosive mixture inside the chamber, for example in the use of paints, varnishes, adhesives, binders, coils impregnated• Dynamic and homogeneous Forced Air Circulation System

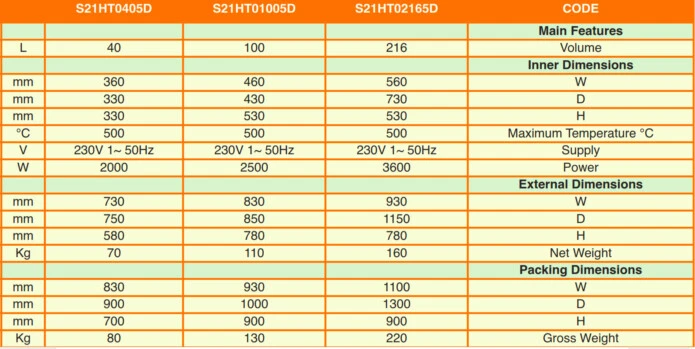

21HT High Temperature Ovens + 500°C

21HT Thermostatic Ovens by Galli suitable for your applications: precise thermostating, heating, drying, polimerization, expansion, cooking, stabilization, tempering, fixing, bonding, heat treatment, accelerated aging, sterilizing, burn-in, inert atmosphere treatments.

PLUS

• AG-System Control: PID Digital Microprocessor, careful and sensitive. Version DAILY, PRO, TALENT

• Range Temperature: from +50°C to 500°C, on request max + 700°C

• Double Digital Display visualize simultaneously the set point and the inner Temperature

• Safety Device, Class 3.1

• Accessories, custom versions, temperatures available on request

• Dynamic and homogeneous Forced Air Circulation System

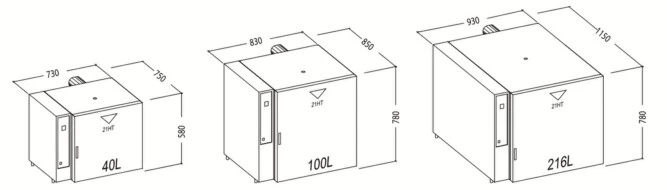

• 3 sizes, bench top model: 40, 100, 216 Litres

• Made in Italy

• Range Temperature: from +50°C to 500°C, on request max + 700°C

• Double Digital Display visualize simultaneously the set point and the inner Temperature

• Safety Device, Class 3.1

• Accessories, custom versions, temperatures available on request

• Dynamic and homogeneous Forced Air Circulation System

• 3 sizes, bench top model: 40, 100, 216 Litres

• Made in Italy

Other Models available :

suitable for your applications: precise thermostating, heating, drying, polimerization, expansion, cooking, stabilization,

Ghibli Thermostatic Ovens GREEN + 300°C : 50, 80 & 100 L natural or forced air system (Through hole for inspection robes)

GTHERM Thermostatic Oven + 260°C : 15, 35,75, 115 &205 L (for applications: precise thermostating, heating, drying, polimerization, expansion, cooking, stabilization, tempering, fixing, bonding)

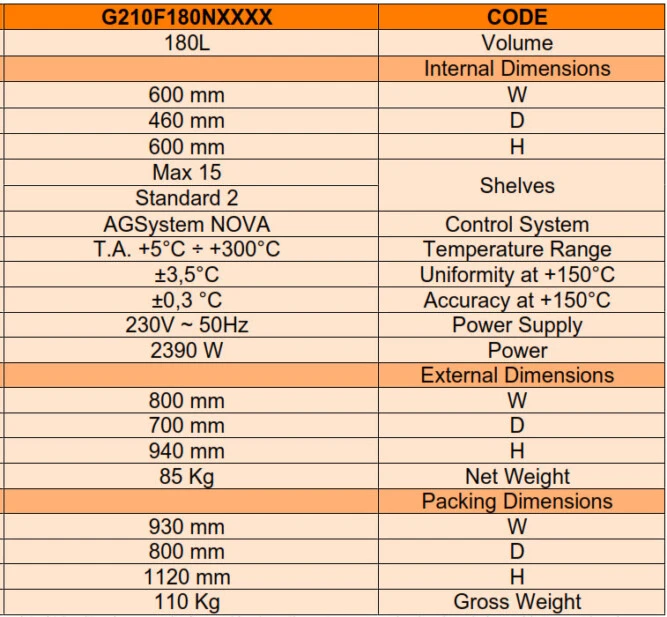

2100 High Performance Oven +300°C : 27, 64,96,180,240,512 L bench top & 250, 432 , 720, 1040 L with wheels ( for applications: precise thermostating, heating, drying, polimerization, expansion, cooking, stabilization, tempering, fixing)

Gibry Hybridization Ovens : +5°C to +99,9°C Adjustable rotisserie up to 20rpm (oven application :southern (DNA), northern (RNA) and western hybridizations, custom focused genotyping, linkage analysis, sequencing-based methylation analysis, FFPE sample analysis, whole-genome gene expression analysis, comparitive genome hybridization, genome tiling, gene expression, micro RNA analysis, pathogen typing, re-sequencing and SNP detection, stripping of microarrays. Hybridization Ovens for molecular biology, cytogenetic analysis, biotechnology sector, biomedical, pharmaceutical industry and research)

21 GV High performance Vacuum Oven : 20, 50, 110 &220 L ( for chemical, pharmaceutical, food, optical, semiconductor industry, research, and biotechnology. Suitable)

21 HT High Temperature Oven + 800°C : 30, 100, 120, 200 L (for your applications: precise thermostating, heating, drying, polimerization, expansion, cooking, stabilization, tempering, fixing)

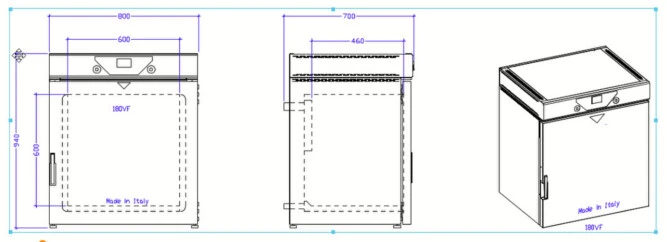

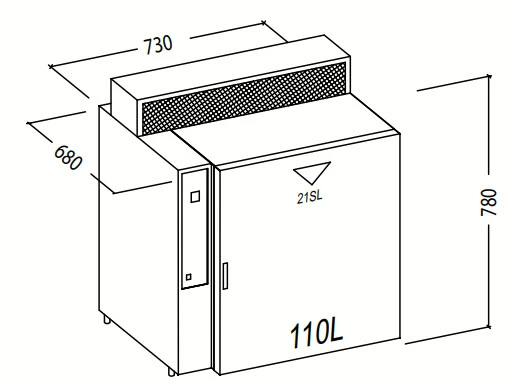

21SL Safety Drying Oven +250°C : 110 L (Suitable for coil coating test procedures, glues, adhesives) (Maximum solvent allowed to +180°C=7,0 g)

21 CB Precision Prove e Test IEC +300°C : 27, 64, 96, 180 L ( for applications: test cables and aging plastics, precise thermostating, heating, drying, polimerization, expansion, cooking, stabilization, tempering, fixing, bonding, heat treatment, accelerated aging, sterilizing, burn-in, inert atmosphere treatments

GOVEN Precision Thermostatic Oven +260°C + 350°C : 300 L Horizontal Forced Air System (suitable for your applications: precise thermostating, heating, drying, polymerization, expansion, cooking, bonding, hardening)

GOVEN ASTM12 Precision Thermostatic Oven Amb. +10,0°C to +350°C : Special Oven 300L (suitable for applications: precise thermostating, heating, drying, polimerization, expansion, cooking, stabilization)

GOVEN 0220 HP Fast Precision thermostatic Oven +450°C ( for Fast Temperature Test, precise thermostating, heating, drying, polymerization, expansion, cooking, bonding, hardening, failure analysis, polyamide curing, accelerated aging, sterilizing, burn-in, inert atmosphere treatment, long-term storage.)

5100 Horizontal Flow Oven +120°C, +260°C +350°C : 306, 504, 840, 1008, 1520, 2080 L (for applications: precise thermostating, heating, drying, polimerization, expansion, cooking, stabilization, […])

5150 Horizontal Flow Oven +120°C, +260°C, +350°C : 730, 1200, 2160, 2850, 2900 L (for applications: precise thermostating, heating, drying, polimerization, expansion, cooking, stabilization)

GLadyBug Small & Compact Laboratory Ovens +200°C : 13 & 30 L ( ideal for your applications: precise thermostating, heating, drying, polimerization, expansion)

HIGH TEMPERATURE OVEN :

Muffle Furnaces High temperature : +1100°C, +1200°C, +1400°C

Muffle Tubular furnaces from +600°C to 1400°C

The High-Performance Thermostatic Ovens model 2100 with Forced Air System are ideal for all those applications where an accurate, reliable, and high-performance device is needed, and are used in research and biological, chemical, and pharmaceutical laboratories.

2100 Thermostatic Ovens are essential in a wide range of tests and drying process, in stability tests, accelerated ageing tests and sterilization treatments.

Control System AGS NOVA

- Touch Screen Color Display.

- AUTOMATIC Function with continuous temperature monitoring.

- PROGRAM Function with 20 Programs, 12 Steps with Ramps and Soaks.

RECORDING Function with Graphic Temperature Recording.

- Set Point and Inner Temperature Visualization.

- Optimized Control Algorithm with PID Actions.

- Autotuning Function.

- Platinum PT100 Probe, Class A.

- “Zero Crossing” Solid State Relays. USB Port.

Temperature Range from Ambient Temperature +5°C to +300°C