The Testing Machine is driven electro-hydraulically.

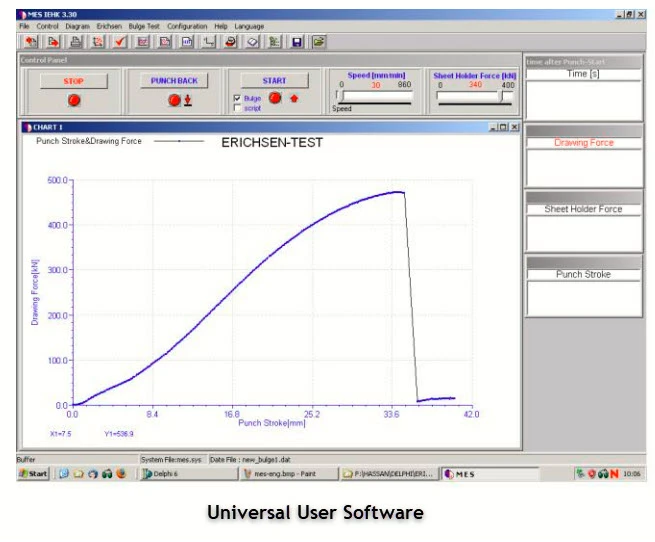

The test sequence can be controlled automatically or manually, as desired.

A programmable logic controller is used to control the functions of the machine.

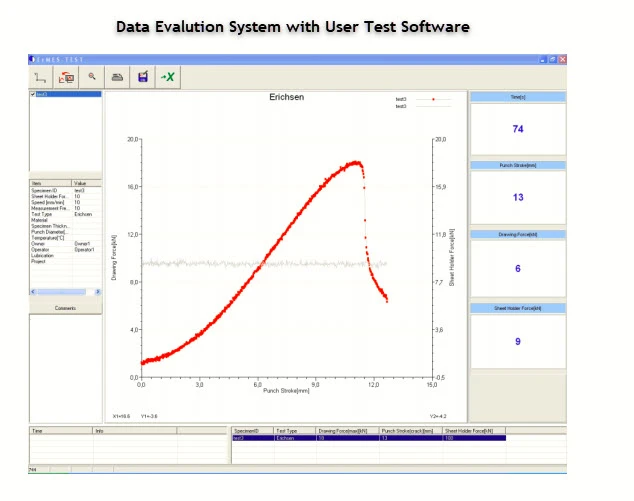

The testing machine is equipped with digital displays for indicating the sheet holder force, the drawing force. as well as the drawing punch stroke.

The triple-acting hydraulic system in conjunction with the general design results in the following cost saving simplifications:

- Blanking press in the test head

- Hydraulic cup ejector

- Fully-automatic test sequence with stop at specimen failure (as of 0.3 mm sheet thickness)

The Sheet Metal Testing Machine, Model 142-Basic, was developed for testing as a means for continuous production control using standardised and other established methods, but also for research into all aspects of testing of sheet metal for deep drawing by studying all that is relevant to sheet metal forming.

Technical Data

Drawing force 142-20 200 kN

Blanking force 142-20 260 kN

Blankholder force 142-20 up to 100 kN

Drawing punch stroke 142-20 approx. 80 mm

Blankholder stroke approx. 38 mm

Drawing punch dia. 142-20 up to 50 mm

FLC test (drawing punch-ø) up to 100 mm

Bulge test (bulge-ø) up to 100 mm

Blank diameter 142-20 up to 120 mm

Drawing speed 142-20 approx. 800 mm/min

Digital displays Resolution:

Drawing punch stroke 0.1 mm (on request 0.01 mm)

Drawing force 0.1 kN

Blankholder force 0.1 kN

Mains supply 400 V / 3 -, 50/60 Hz (other voltages on request)

Power required 9.4 kW

Dimensions 142-20 approx. 2000 x 1120 x 1300 mm

Weight, net 142-20 approx. 1300 kg

Working material approx. 230 l hydraulic oil (HLP 32 ISO)