Non-dest Traditional Digital

Coatings & Industry > Physical properties > Thickness Dry Film

MiniTest 650

The rugged coating thickness gauge MiniTest 650 follows its long-time proven predecessor model MiniTest 600 in the line of gauges with a fixed external probe offering measurement of all non-magnetic coatings on steel.

It was especially designed to work in rough environments as well as on on abrasive surfaces, e.g. shot-blasted steel, plasma spray coated surfaces.

Enables 1-point and 2-point calibrations.

Performance features

- Coating thickness measurement up to 3 mm

- Probe for quick measurements on steel

- Wear-resistant probe tips with practically unlimited durability

- USB-interface to transfer measuring data to a PC

- Statistical evaluation of readings

Applications

Non-destructive coating thickness measurement:

non-magnetic coatings, e.g. paint, enamel, chrome, zinc on ferromegnetic substrates (e.g. steel)

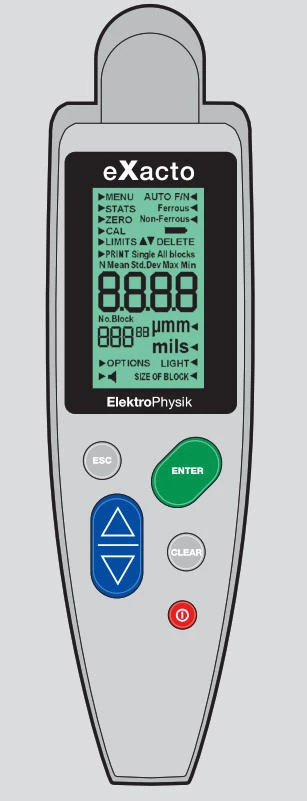

eXacto

Compact coating thickness gauge with self-explanatory menu operation for measurements of non-magnetic coatings on steel

0 ... 3000 µm

Innovative technology for precise and reliable measurements with internal probe.

Product features

■ Compact gauge with integrated compartment for storing standards for checking accuracy

■ Manual preselection of the measuring principle possible

■ Convenience through backlit display

■ Tolerance monitoring through limit function and alarm signal

■ Single and block value statistics

■ Data memory for up to 90 single readings

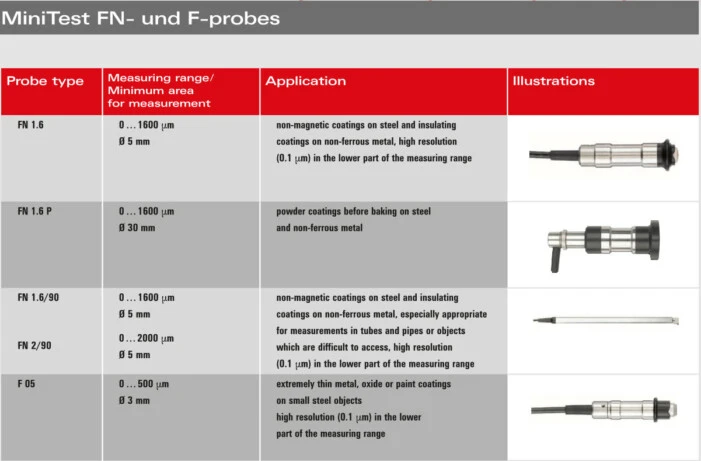

MiniTest 3100

Application: Non-destructive measurement of:

non-magnetic coatings, e.g. paint and zinc on ferrous substrates

insulating coatings, e.g. paint and anodizing coatings on non-ferrous metals

non-ferrous metal coatings on insulating substrates

MiniTest 3100

- Memory structure to be defined variously for users with different applications

- Statistical evaluation from various groups

wide range of wear-resistant probes which can be adapted to different applications

universal probe for measurements on steel and non-ferrous metals

high measuring accuracy and reproducibility

storage and evaluation of measuring values

MiniTest 3100 possesses a total memory capacity of 10,000 readings and the possibility to store readings in 10 application memories with 10 batches each. A calibration once performed remains in the application memory. Statistical evaluation of a measuring series allows the user to assess the coating with mean value, max., min., standard deviation and number of readings taken within one measuring series.

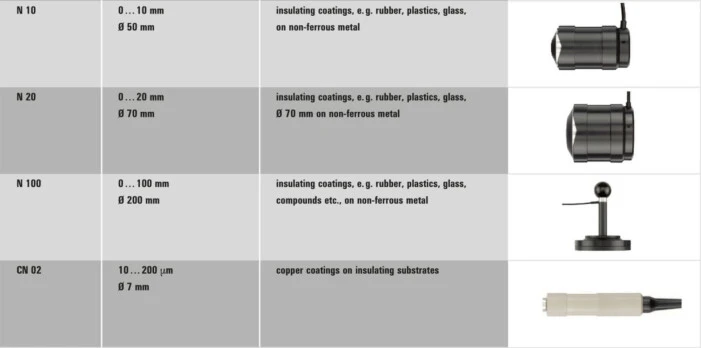

Coating Thickness Gauge LAYERCHECK 700 FN

Model 700 FN & universal probe (FN) with automatic measuring technique for measurements on all non-magnetic coatings on steel and all insulating coatings on non-ferrous metals.

Including probe for measurements :

- on steel (measuring range 0 - 2,000 µm )

- and on on non-ferrous metals (measuring range 0 - 2,000 µm ),

with statistics, two-point calibration, readings in microns or mils at choice, backlight display and interface RS 232

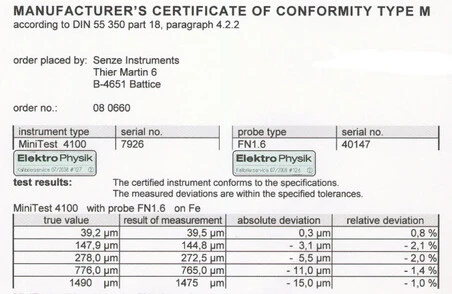

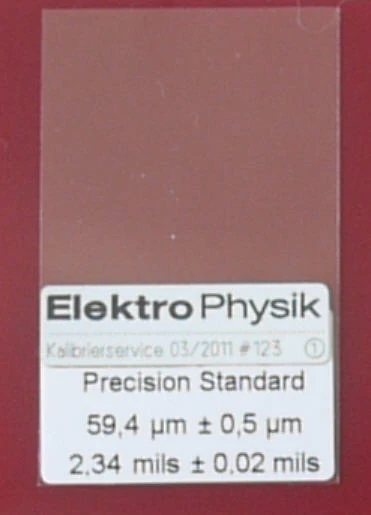

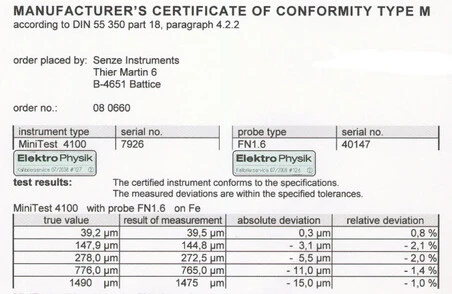

Calibration foils

Calibration foils with thicknesses ranging from 10 μm up to 8 mm

Option: Manufacturer’s certificates M according to DIN 55350 part 18 proving the accuracy of calibration foils and/or gauge