Different needs

Graphic & Printing Industry > Ink properties > Surface tension

Do you have to increase surface tension ?

Each material has its particular surface tension level.

It is necessary to know the minimal surface tension required to make sure to achieve a good printing or sticking process.

Ex: PP, PE ...

With our test inks, You will find out the surface tension of your material.

If you want to increase it, you can use :

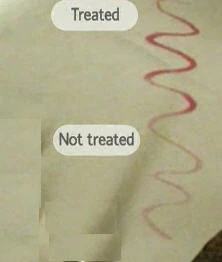

PLASMA Treatment :

Gas plasma surface treatment is an ideal technology for the surface modification of plastic, textile & film products while enabling hydrophilic and hydrophobic coatings.

CORONA Treatment

Corona treatment is the most common method of increasing surface energy on substrates to promote adhesion when printing, coating or laminating.

To improve printing

It is necessary to increase the surface tension of your material because too low, the ink doesn't adhere. To determine the surface tension of your materials, you can use our test inks range.

Printing Type : with solvent based inks with water based inks

Flexography 38 44

Heliography 40 46

Offset 42 46

Silk-screen printing 44 46

To improve sticking

If your surface tension is to low, you have to increase it otherwise the glue doesn't adhere.

To find out the surface tension of your materials, you can use our test inks range.

Usually, gluing needs a dyne level of material at least 40 dynes/cm for classic glue.

For metal, ceramic or glass: to test the cleanness

You can test the cleaness of metal, ceramic and glass with our test inks (a range of measure from 28 to 71 dynes).

If the dyne level found with our inks for your material is near his natural dyne level, it means it is clean and vice versa.

If it isn't clean, you can clean it with CORONA and PLASMA