Foil Thickness gauge

Coatings & Industry > Material properties > Material Thickness

Analog Foil Thickness Gauges

This handy instrument is used exclusively to measure the thickness of thin foils (aluminium, tinplate,paper...)

The frame has the required rigidity, the insulation of the handle prevents transfer of heat from the hand of the user to the sensitive mechanical parts of the Dial Gauge.

Model 497 :

Net weight, approx.: 100 g

Measuring range: 0 - 1000 μm over 5 pointer revolutions

Scale : 0 - 200 μm with 1 μm divisions

Readout accuracy: ± 1 μm

Depth of throat: 30 mm

Size of support face: approx. 6 mm dia., flat, = approx. 30 mm2

Measuring pressure: approx. 1.2 N, = approx. 0.04 N/mm2

Foil Dial Thickness Gauge F 1000/30

Reading 0.001 mm

Range 1 mm

Depth of jaw 30 mm

Range per revolution 0.2 mm

Dial reading 0-100 / 0-100

Plexi glass glare free

Bezel-Ø 58 mm

Accuracy according to manufacturing standard 0.0500.9.0001, hysteresis fu however not checked

Standard contact point 6.35 mm Ø flat

Optional contact :

- points 10 mm Ø flat,

- upper contact point convex r 15 or r 40,

- lower contact point 6.35 mm Ø flat

- lower contact point convex r 15

- spherical

Foil Dial Thickness Gauge F 1101/30

Reading 0.001 mm

Range 1 mm

Range per revolution : 0,1 mm

Depth of jaw 30 mm

Maximum error 3 μm

Standard contact points 6,35 mm Ø flat

Another similar Foil Dial Thickness Gauge, but only with 1 hand and a range of 0.1 mm:

Foil Dial Thickness Gauge F 1101/30-0.1

Reading 0.001 mm

Range 0.1 mm

Range per revolution : 0,1 mm

Depth of jaw 30 mm

Maximum error 1.5 μm

Standard contact points 6,35 mm Ø flat

The initial contact force is approximately 1.5 N.

On request the instrument can be supplied with a lower initial contact force of 0.7 N.

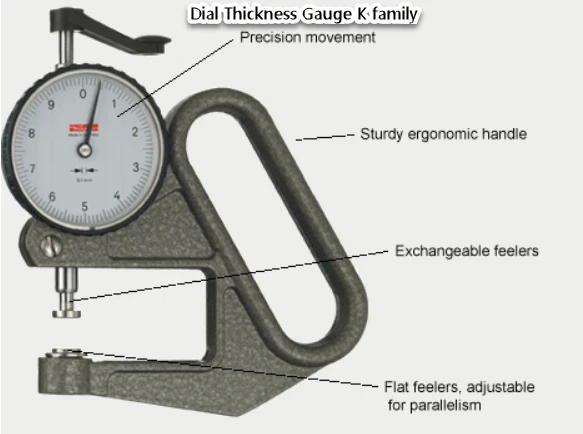

Dial Thickness Gauge K 50/2

Reading 0.1 mm

Range 20 mm

Range per revolution 10 mm

Bezel-Ø 58 mm

Depth of jaw 50 mm

Accuracy according to manufacturing standard 0.0100.9.0004,

hysteresis fu however not checked

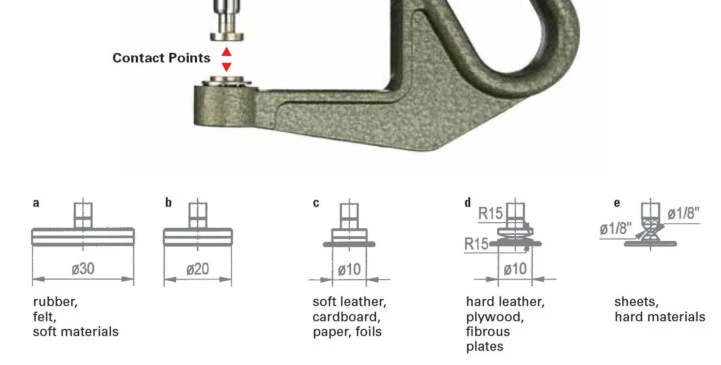

Standard contact point form c

Optional contact points forms a, b, d or e

Resolution 0.001 mm

Range 3 mm

Depth of jaw 30 mm

Pressure : 1,7 N +/- 20%

Output RS 232 / USB

Maximum error 3 μm

Power supply : Lithium batterie 3 V (8000 hours)

Date output : Rs232 or USB

Standard contact points 6,35 mm Ø flat

Dial Thickness Gauge K 50

Reading 0.1 mm

Range 10 mm

Range per revolution 10 mm

Bezel-Ø 58 mm

Depth of jaw 50 mm

Accuracy according to manufacturing standard 0.0100.9.0004,

hysteresis fu however not checked

Standard contact point form c

Optional contact points forms a, b, d or e

Dial Thickness Gauge K 50/3

Reading 0.1 mm

Range 30 mm

Range per revolution 10 mm

Bezel-Ø 58 mm

Depth of jaw 50 mm

Accuracy according to manufacturing standard 0.0100.9.0004,

hysteresis fu however not checked

Standard contact point form c

Optional contact points forms a, b, d or e

Dial Thickness Gauge K 50/5

Reading 0.1 mm

Range 50 mm

Range per revolution 10 mm

Bezel-Ø 58 mm

Depth of jaw 50 mm

Accuracy according to manufacturing standard 0.0100.9.0004,

hysteresis fu however not checked

Standard contact point form c

Optional contact points forms a, b, d or e

Dial Thickness Gauge K 300

Reading 0.1 mm

Range 30 mm

Range per revolution 10 mm

Bezel-Ø 58 mm

Depth of jaw 300 mm

Accuracy according to manufacturing standard 0.0100.9.0004,

hysteresis fu however not checked

Standard contact point form c

Optional contact points forms a, b, d or e

Model shown: K 300 special version with additional weights and special contact points Ø 50 mm

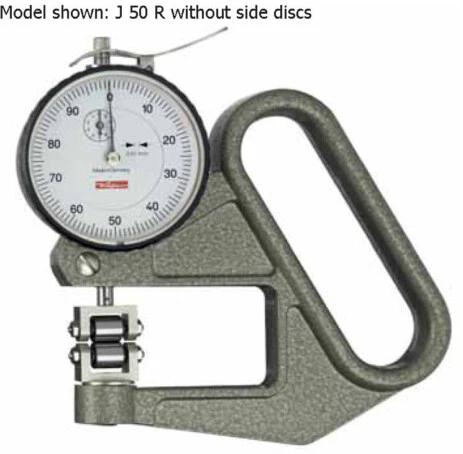

Dial Thickness Gauge J 50 R

This model has side discs at the lower roller for guiding the thread. It is therefore suited for measuring the thickness of wires and threads especially in continuous motion.

Dial Thickness Gauge J 50 R without side discs

This model has no side discs at the lower roller.

It is therefore suited for the measurement of paper, foil, metal and sheet. without side discs

Dial Thickness Gauge J 50 R

Dial Thickness Gauge J 50 R with side discs

Reading 0.01 mm

Range 5 mm

Range per revolution 1 mm

Bezel-Ø 58 mm

Depth of jaw 50 mm

Standard contact point rollers with side discs

Width of the rollers 8.7 mm

Ø of the rollers 8.4 mm

Thickness Gauges with roller contact points are available in many variants:

- Dial Thickness Gauge K 50 R reading 0.1 mm, range 10 mm

- Dial Thickness Gauge J 50/3 R reading 0.01 mm, range 20 mm

- Dial Thickness Gauge K 100 R reading 0.1 mm, range 10 mm depth of jaw 100 mm

- Dial Thickness Gauge K 200 R reading 0.1 mm, range 10 mm depth of jaw 200 mm

- Dial Thickness Gauge J 200 R reading 0.01 mm, range 10 mm depth of jaw 200 mm

- Dial Thickness Gauge F 50 R reading 0.001 mm, range 5 mm depth of jaw 50 mm

- Digital Thickness Gauge JD 50 R resolution 0.01 mm / .0005” range 10 mm / .400” depth of jaw 50 mm

- Digital Thickness Gauge JD 100 R resolution 0.01 mm / .0005” range 10 mm / .400” depth of jaw 100 mm

- Digital Thickness Gauge FD 50 R resolution 0.001 mm / .00005” range 10 mm / .400” depth of jaw 50 mm

Specifications of the Technical data for Metric Dial Thickness Gauge

Type Reading Range Depth of Jaw Form of the feeler available

K 15 0,1 mm 10 mm 15 mm 6,35 mm Ø, flat, 10 mm Ø, flat, convex or spherical

K 15/2 0,1 mm 20 mm 15 mm

K50 0,1 mm 10 mm 50 mm a, b, c, d or e

K 50 with lifting device 0,1 mm 10 mm 50 mm

K 50/2 0,1 mm 20 mm 50 mm

K 50/3 0,1 mm 30 mm 50 mm

K 50/5 0,1 mm 50 mm 50 mm

K 100 0,1 mm 30 mm 100 mm

K 200 0,1 mm 30 mm 200 mm

K 300 0,1 mm 30 mm 300 mm

K 400 0,1 mm 30 mm 400 mm

J 12 0,01 mm 8 mm 12 mm 6,35 mm Ø, flat or spherical

J 15 0,01 mm 10 mm 18 mm 6,35 mm Ø, flat, 10 mm Ø, flat, convex or spherical

J 45 0,01 mm 10 mm 45 mm

J 50 0,01 mm 10 mm 50 mm a, b, c, d or e

J 50 with lifting device 0,01 mm 10 mm 50 mm

J 50 R 0,01 mm 5 mm 50 mm Rollers

J 50 R without side discs 0,01 mm 5 mm 50 mm Rollers without side discs

J 50 W 0,01 mm 10 mm 50 mm Pin with coller for pipe walls

J 50/3 0,01 mm 20 mm 50 mm a, b, c, d or e

J 50/3 WP 0,01 mm 20 mm 50 mm For corrugated boards

J 100 0,01 mm 10 mm 100 mm a, b, c, d or e

J 200 0,01 mm 10 mm 200 mm

J 200/30 0,01 mm 30 mm 200 mm

F 1101/30 0,001 mm 1 mm 30 mm 6,35 mm flat, convex or spherical

Corrugation Dial Thickness Gauge J 50/3 WP to EN 494

This handy Dial Thickness Gauge is used exclusively to measure the thickness of fibre - cement profiled sheet and other corrugated plates or irons. It is equipped with special contact points which have a camber of 2 mm and a width of 10 mm.

The concentric millimetre pointer allows easy and safe reading of the Dial Thickness Gauge.

J 50/3 WP to EN 494

Reading 0.01 mm

Range 20 mm

Range per revolution 1 mm

Bezel-Ø 58 mm

Accuracy according to manufacturing standard 1.0200.9.0014, hysteresis fu however not checked

Standard contact point radius 2 mm

This Stand converts the Dial Thickness Gauges K 50, K 100, J 50, J 100 and F 1101/30 as well as the respective digital models, designed for hand-held use, to table models.

Fleece Dial Thickness Gauge 9073-2

to DIN EN ISO 9073/2 – edition 1997-2

This Dial Thickness Gauge is used exclusively to Fleece Dial Thickness Gauge 9073-2 measure the thickness of normal fleece to DIN EN ISO 9073/2 (part 5.1). It is equipped with special contact

points and has a special contact force to meet DIN EN ISO 9073/2 requirements.

The concentric millimetre pointer allows easy and safe reading of the Dial Thickness Gauge.

Precision Measuring Table P 7

The Precision Measuring Table P 7 is sturdily built and accurately finished. Its surface plate is hardened, ground and lapped.

It is separated from the main body resting on three support points.

The carrying arm is adjustable for height on the

The carrying arm is adjustable for height on the vertical column.

The column is hardened and ground.

Measuring capacity : 100 mm

Depth of throat

Depth of throat : 50 mm

Column-Ø

Column-Ø : 22 mm

Base-Ø

Base-Ø : 50 mm

Holder opening

Holder opening : 8 mm H7

It is separated from the main body resting on three support points.

The carrying arm is adjustable for height on the

The carrying arm is adjustable for height on the vertical column.

The column is hardened and ground.

Measuring capacity : 100 mm

Depth of throat

Depth of throat : 50 mm

Column-Ø

Column-Ø : 22 mm

Base-Ø

Base-Ø : 50 mm

Holder opening

Holder opening : 8 mm H7

If desired, the Measuring Table P 7 is also available with special fittings:

Measuring Table P 7 with fluting

Measuring Table P 7 with measuring ball Ø = 30 mm

Measuring Table P 7 with measuring height of 165 mm

Measuring Table P 7 with measuring height of 215 mm

Measuring Table P 7 with measuring height of 315 mm

Measuring Table P 7 with circular support plate of Ø 80 mm

Measuring Table P 7 with circular support plate of Ø 90 mm

Measuring Table P 7 with adjustable support plate for use as base for table-thickness gauges

Delivery without Dial Gauge.

Measuring Table P 7 with fluting

Measuring Table P 7 with measuring ball Ø = 30 mm

Measuring Table P 7 with measuring height of 165 mm

Measuring Table P 7 with measuring height of 215 mm

Measuring Table P 7 with measuring height of 315 mm

Measuring Table P 7 with circular support plate of Ø 80 mm

Measuring Table P 7 with circular support plate of Ø 90 mm

Measuring Table P 7 with adjustable support plate for use as base for table-thickness gauges

Delivery without Dial Gauge.

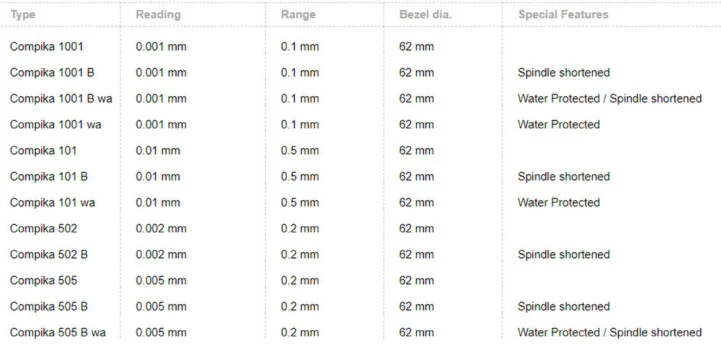

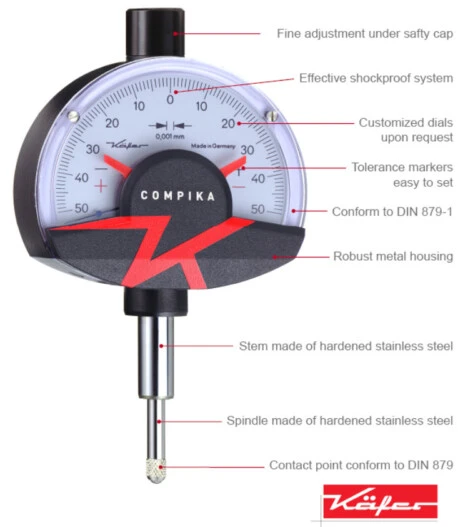

Compika - Comparator Gauges

The Comparator Gauges Compika offer a high degree of security and precision.

They are based on a solid and well thought-out construction taking into account the latest technology.

They are manufactured by the most up-to-date methods.

The following quality features characterize our manufacturing programme of Comparator Gauges Compika:

- Their design conforms to the requirements of DIN 879-1. This applies not only to the dimensions but also to permitted spans of error, hysteresis and measuring pressure. Effective shockproof system

- Pinions and shafts of the movement are jewelled

- After removal of the safety cap the adjustment screw on top of the case allows simple and safe zero setting of the instrument over the total measuring range. A safety cap prevents unintentional turning of the fine adjustment facility.

- Stem and spindle are made of hardened stainless steel.

- The measuring spindles are very sensitive on account of their accurate guides.

- Additional overtravel assists with the insertion of workpieces into the measuring device.

- The clear scale is shadow free.

- The red tolerance markers are easy to recognize and to set.

- On request all our models are available with a reduced pressure of 0.5 N.