Mek Test

Coatings & Industry > Physical properties > Curing effect

Surface Hardness Abrasion Tester & Crock Meter

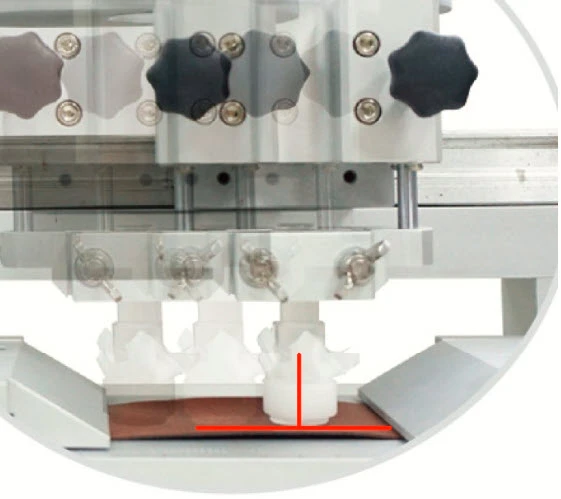

319-QC-621H of main purpose is for measure surface treatment such as painting, plating, coating, dyeing and finishing the design of the machine.

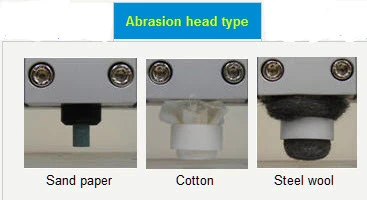

It can use cotton, sand paper, steel wool and eraser to test specimen of wear condition.

This tester can cater various different standard of requirement to set condition for testing such speed, stroke, specimen appearance, abrasion head and load.

"Solvent rubbing resistance" is another way of determining the curing effect.

The solvent rub technique is use for assessing the MEK resistance of ethyl silicate .

The MEK resistance of some two-component ethyl silicate zinc-rich primers has been shown to correlate well with the cure of the primer as determined by diffuse reflectance infrared spectroscopy.

Industry: Plastic, Electronic, Textile, Print, Coatings

Warning : The astm D 4752 prescribes to place the properly protected index finger into the center of the pad, with the index finger at a 45° angle to the test surface, with this instrument the index is at 90 °.