Pinhole Detector

Coatings & Industry > Physical properties > Porosity & Permeability

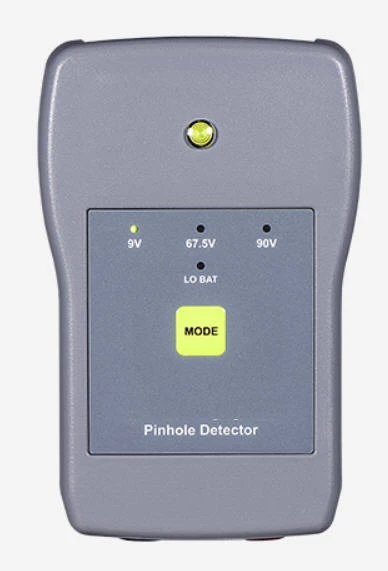

Pinhole Detector

Low Voltage Holiday Detector : Pinhole Tester 9V/67.5V/90V

ISO 29601: Paints and varnishes. Corrosion protection by protective paint systems.

Assessment of porosity in a dry film.

The Pinhole Detector uses the wet sponge principle to detect through-pinholes, cracks and damaged areas

on non-conductive coatings on conductive substrates.

These flaws would eventually lead to corrosion and premature failure of the coating.

Operation is by a wet sponge, moistened with a wetting agent, being moved over the coating.

The wetting agent penetrates any pinhole and makes a conductive path through to the substrate.

The Pinhole Detector detects this conductive path and indicates that a pinhole has been detected by

sounding an audible alarm and giving a visual warning by a red flashing indicator.

The Pinhole Detector has test voltages of 9 Volts, 67.5 Volts and 90 Volts, which are easily selectable.

The Calibration Certificate with traceability to UKAS is an optional extra.

The Certificate is supplied as hard copy.

Supplied in an industrial foam-filled Carrying Case with 150 mm Sponge Assembly and 5 m Earth Cable.