Mobile Measuring Systems

Coatings & Industry > Material properties > Material Testing Machines

Mobile Measuring Systems

Mobile and stationary measuring systems, with up to four channels for simultaneous data acquisition of physical quantities such as force, distance, pressure as well as speed, torque or angle of rotation. The flexibly equipped measuring amplifiers allow the connection of strain gauge sensors, digital encoders and analog signal sources.

Hydraulic load cells: Hydraulic force measuring devices for measuring forces that occur. The method is based on the hydraulic transmission of forces acting on the piston of the force transducer. This hydraulic pressure is directly displayed on a display unit scaled in Newton. The force gauges are ideal for maintenance and adjustment work and for use in plants, machines and systems of all kinds.

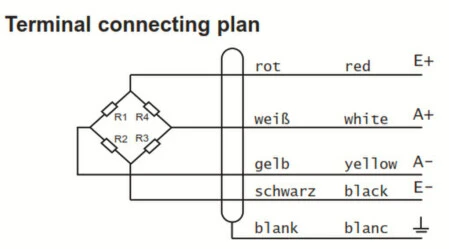

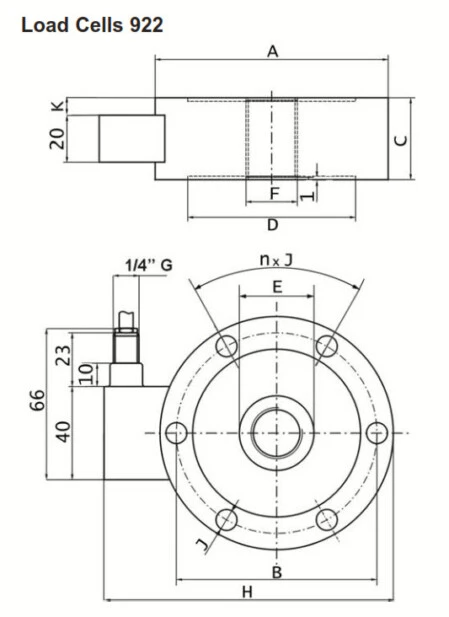

Force measuring system: For the acquisition of mechanical quantities on the basis of strain gauge sensors.

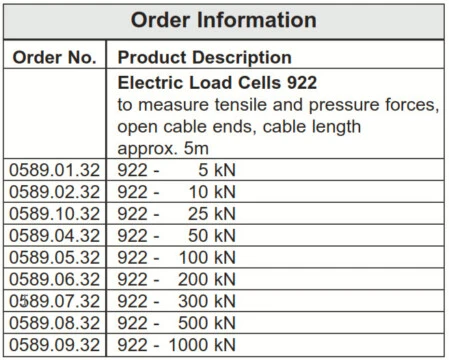

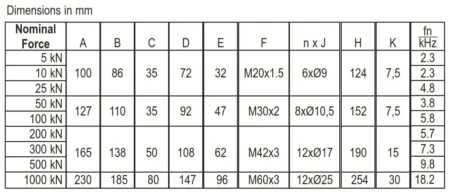

Electrical force transducers: The electrical force transducers reflect the latest state of sensor technology and take into account the most varied customer requirements. These force transducers are used wherever tensile and compressive forces are measured with maximum accuracy, e.g. in materials testing and in research and development. But also in the industry these force transducers are used in the fields of

automation, the control of press-fit processes and the joining technology the right choice.

automation, the control of press-fit processes and the joining technology the right choice.

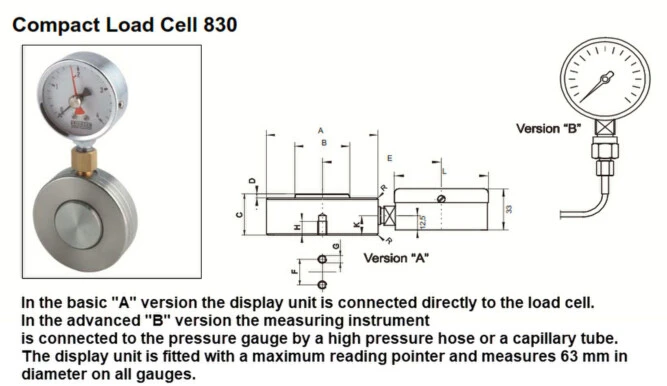

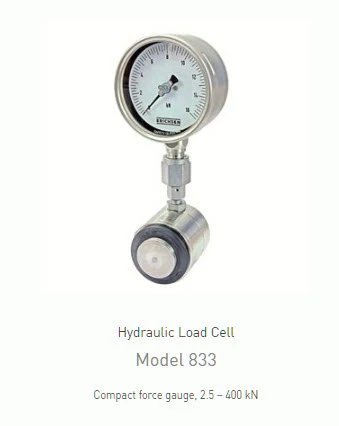

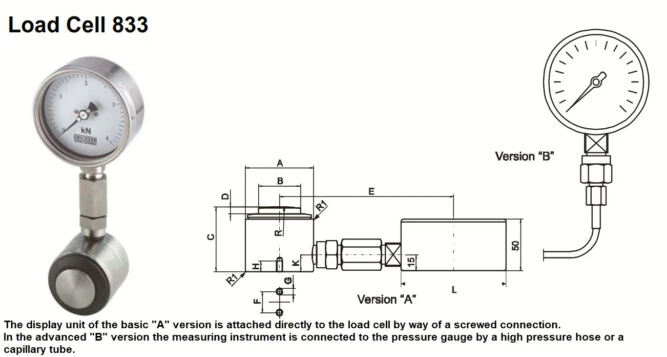

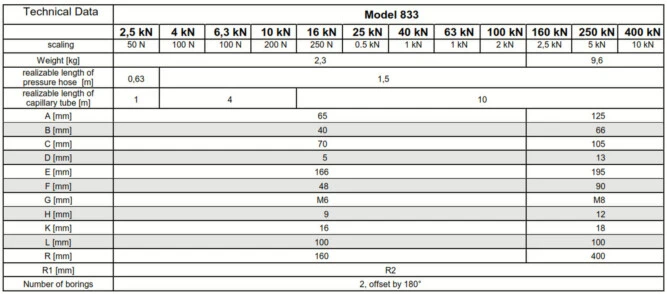

Hydraulic Load Cell Model 830 - 833 - 844

ERICHSEN's force measuring instruments enable you to measure the occurring forces in a simple and cost-effective manner.

The operating method is based on the hydraulic transmission of forces acting on the piston of the force transducer.

This hydraulic pressure is displayed directly on a Newton-scaled display instrument.

Hydraulic force gauges are preferably for static usage.

The force rise time (relative to nominal load) should therefore not be less than one second, since rapid load changes could damage the display instrument.

Blows associated with changing forces can be damped, however, using the appropriate throttles. All force gauges are made of stainless steel.

Fields of application

Compact load cells are ideal for maintenance and adjustment work.

This particular series has been designed primarily for carrying out occasional force checks rather than for continuous loading.

Their compact dimensions make these instruments extremely versatile. By using the appropriate accessories the measured value can also be shown on a remote display.

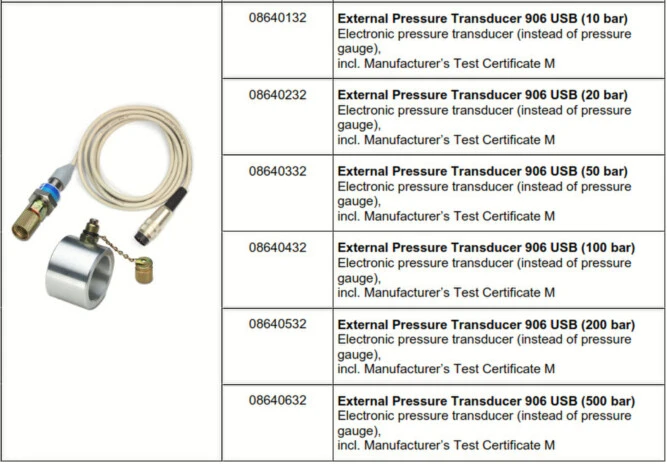

The readings can be transmitted to the PHYSIMETER ® 906 MC-E and 906 USB by way of a pressure transducer.

Fields of application

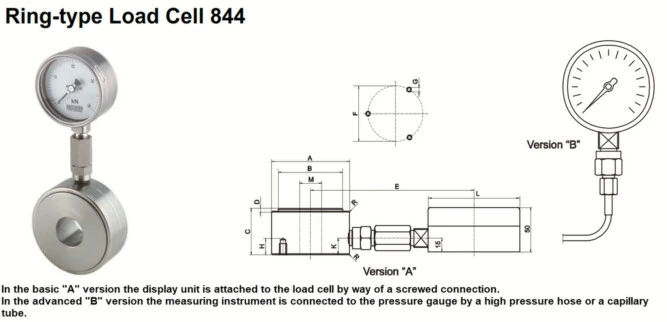

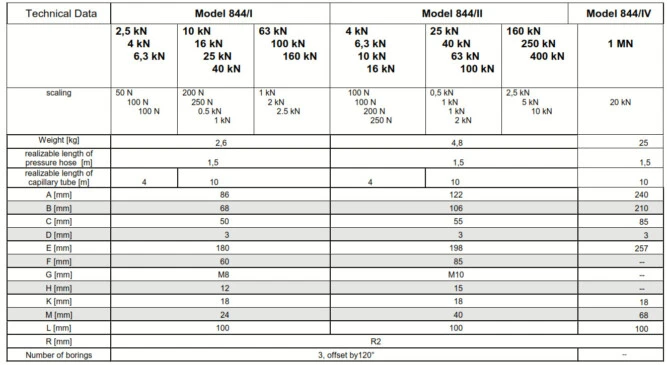

Load cells in the 844 series are suitable wherever a shaft needs to be fitted through the measuring device.

These instruments are specifically designed as a permanent monitoring facility for axial and bearing forces. They are equipped with a high-accuracy dial gauge which has a large diameter (100 mm) and a zero offset compensation.

By using the appropriate accessories, the measured value can also be shown on a remote display.

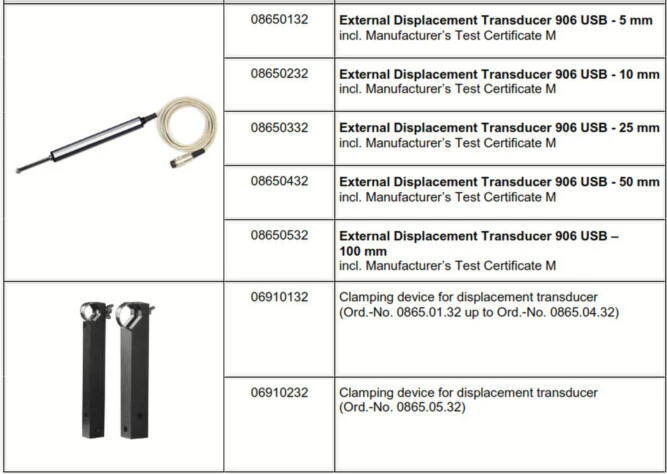

The readings can be transmitted to the PHYSIMETER ® 906 MC-E and 906 USB by way of a pressure transducer.

Load cells - Display instrument Model 975

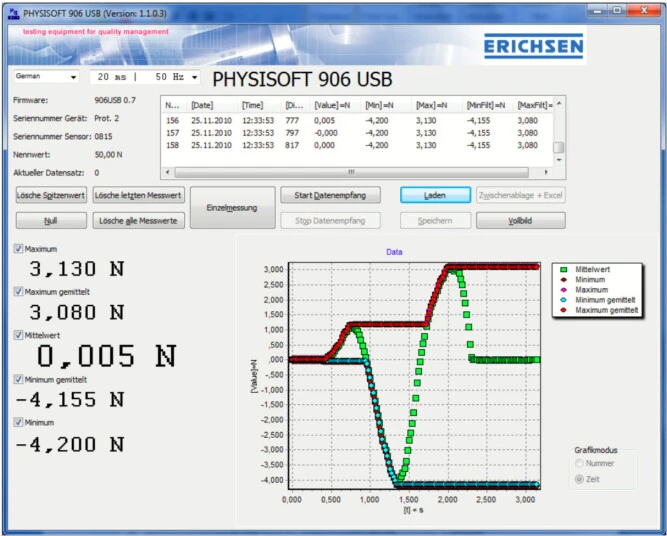

The Model 975 AP display instrument is designed to easily measure and display forces when working with ERICHSEN strain gauge force transducers. It can be used anywhere where forces need to be detected simply and quickly.

This instrument is versatile because it is easy to handle.

The measuring and display electronics are designed to operate with mains power. They are enclosed in a robust aluminium housing.

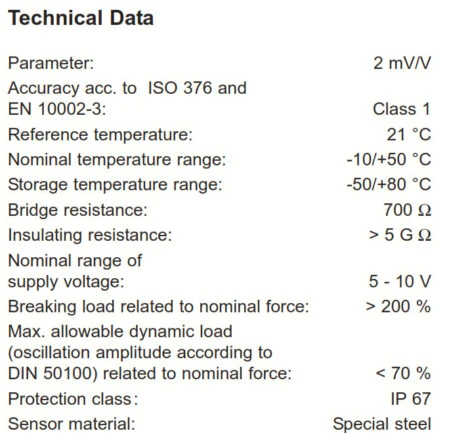

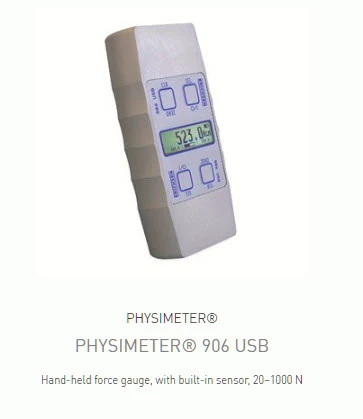

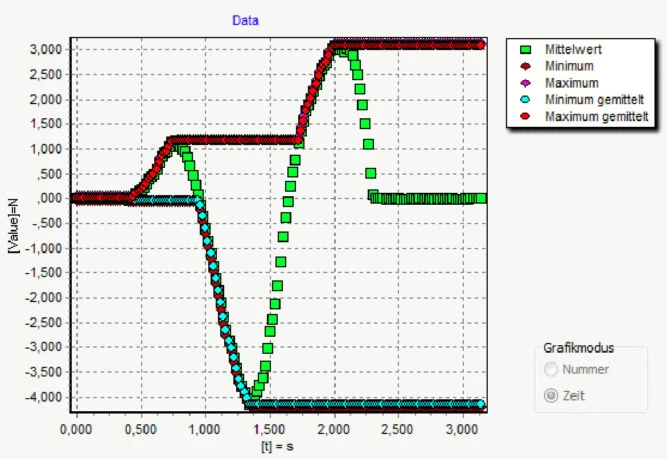

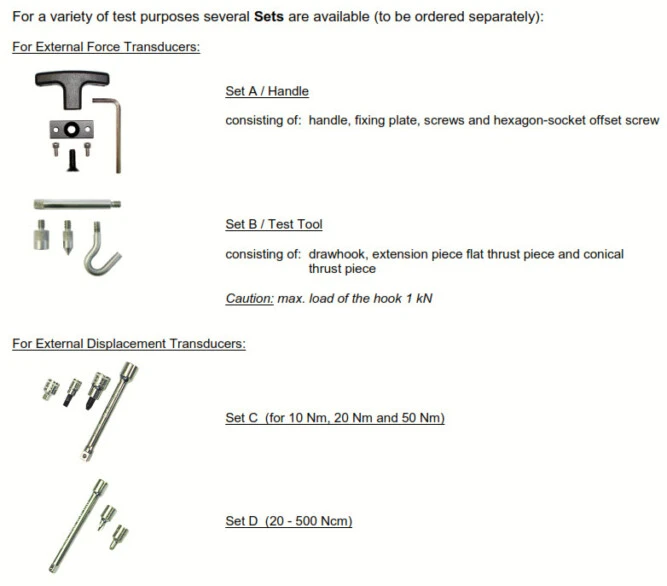

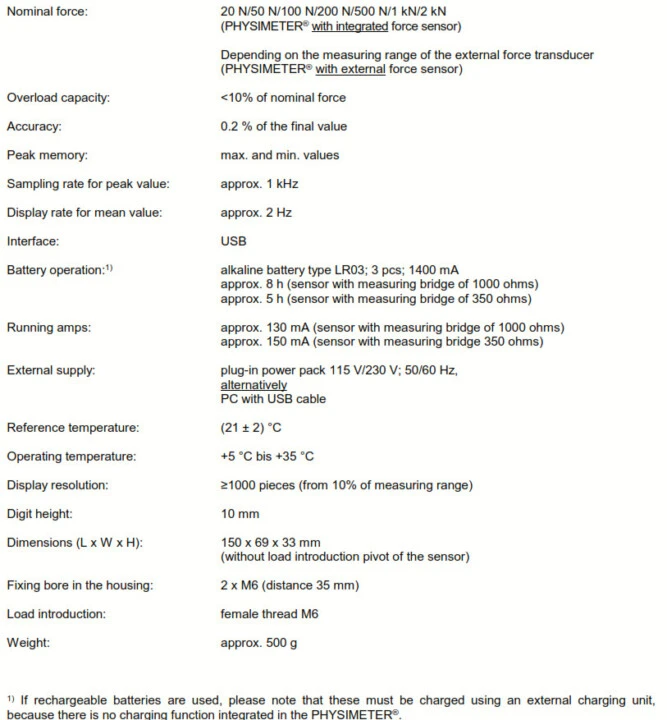

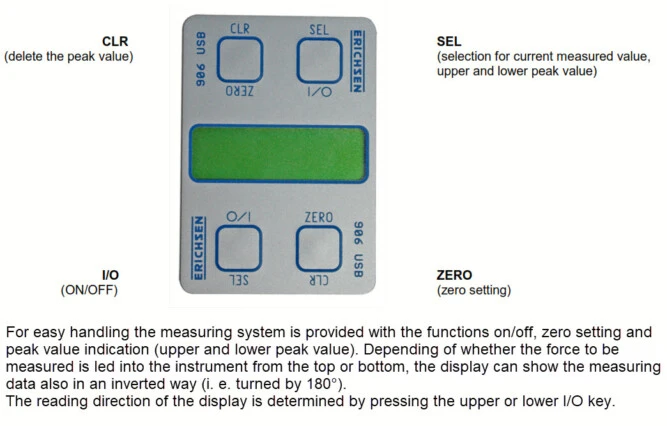

The Measuring System PHYSIMETER ® 906 USB is used for the acquisition of mechanical parameters based on wire strain gauge sensors.

Two versions are available:

PHYSIMETER ® 906 USB with an integrated force sensor and

PHYSIMETER ® 906 USB to connect an external sensor.

For the power supply three micro-batteries (type LR03) or alternatively a plug-in power pack is required.

The data transmission of PHYSIMETER to PC is made via USB interface (USB cable included in scope of supply).

The measuring and evaluation software PHYSISOFT 906 USB is available free of charge at https://www.erichsen.de/en-gb/service/downloads.

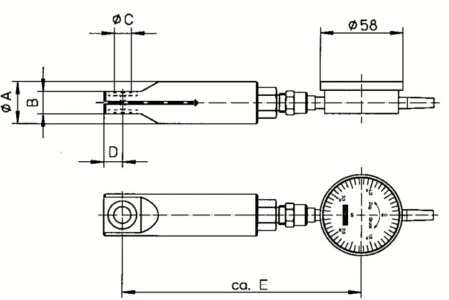

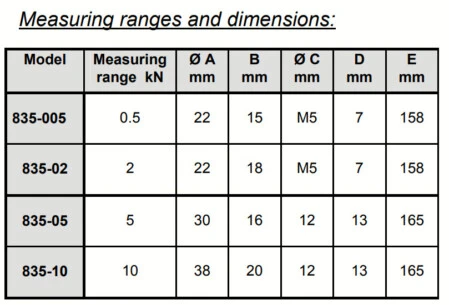

Point Force Transducer Model 835

Point force measuring gauge, 500 N – 10 kN

Special versions:

Customized versions can be designed for special applications, e.g. for measuring the tensile force of through-running wires, or equipped with tension shackles for installing overhead lines at prescribed tensile strain rates, etc.

Finishes:

High-gloss chromium-plated

Accessories:

- Pressure piece (chromium-plated)

- Universal joints (galvanized) for tensile force