142-40

Metal Testing > Sheet Metal Testing > Model 142

142-40 Universal-Sheet Metal Testing Machine

The Universal Sheet Metal Testing Machine Model 142-40 with electro-hydraulic drive, fully automatic test sequence and switch off at specimen failure, max. drawing force of 400 kN.

Order number: 101-00480331

Application: This Testing Machine can be used not only to perform effortlessly, quickly and accurately all important and known deep drawing tests for ferrous and non-ferrous metals, but it is also designed for a large number of additional technological investigations like the ERICHSEN Cupping Test and the ERICHSEN Deep Drawing Cup Test on sheet and strip.

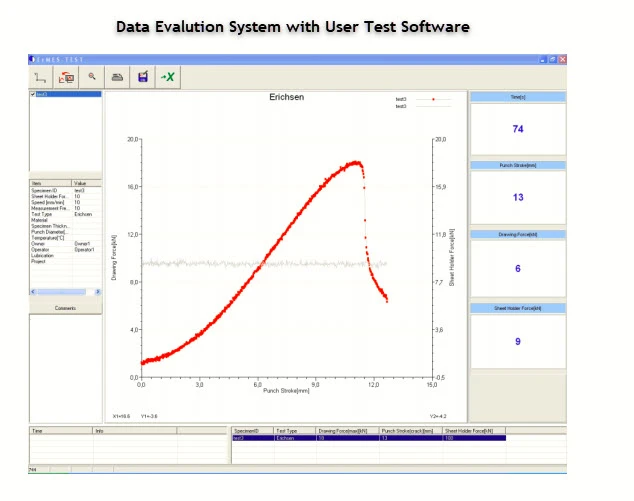

ErMES

Data logger for recording the measurements such as drawing force, blank holder force and stroke; the connection is made by an USB connection.

The software included in the scope of supply runs under WIN VISTA, 7, 8 and 10.

The scope of supply includes PC, VDU and printer.

142-40 Basic vs 142-40

The basic model is oriented towards production control, and specific needs in Research and Development. The 142-40 model is the ideal tool for the R&D department whose concern is the response to current needs and adaptation to future needs.

Model 142-40 |

Proportioning valve control |

ErMES Data logger for recording the measurements |

MES for control, adjustment, documentation and filing of measuring data;recording of the measurements and creation of scripts (test sequences) |

Hydraulic test head opening |

Blankholder force 400kN |

Drawing speed 900mm/min |

Oil volume: 230l |

Oil/Water Cooling System for use at increased ambient temperatures |

MODEL 142-40 BASIC |

| Manual valves |

ErMES Data logger for recording the measurements |

Manual test head opening |

Blankholder force 220kN |

Drawing speed 500mm/min |

Oil volume: 90l |

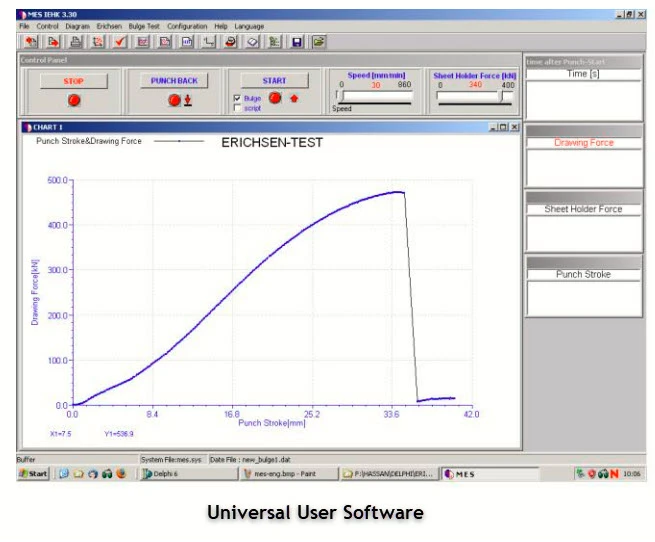

MES - Universal User Software

for control, adjustment, documentation and filing of measuring data of the sheet metal testing machine.

Software for recording of force displacement diagrams such as drawing force and blank holder force, stroke.

Creation of scripts (test sequences); presetting of freely selectable parameters such as drawing and blank holder force as well as drawing speed.

The measuring system integrated in the sheet metal testing machine is designed in modular system with analogue and digital inputs and outputs.

Hereby drawing force, blank holder force and stroke are acquired:

The data are exchanged with the PC via a USB connection.

This programme enables to create and evaluate test sequences for tests e.g. Erichsen deep-drawing cup test, bore expanding test, bulge test, Erichsen deep drawing test.

The scope of supply includes PC, VDU and printer.

Mes Soft : for sheet holder force data and drawing punch speed data the 142-40 requires two options :

- the Proportioning valve control of sheet holder force in the range between 0 kN and 400 kN- the Proportioning valve control of drawing punch speed in the range between 0 and 900 mm/min