Digital Roughness Testers

TR 100

Pocket-sized and economically priced!

Both Ra and Rz parameters in one instrument

Software calibration

Rechargeable batteries

Large measuring range suitable for most materials

Piëzo-electric pick-up stylus for external surfaces

Roughness parameter Ra, Rz

Units µm / µinch

Measuring range Ra: 0.05-15.0 µm

Rz: 0.1-50,0 µm

Cut-off lengths 0.25mm, 0.8mm, 2.5mm

Filter 2CR

Functions Dynamic display during testing, sound signal start-test-ready,

auto-off 90 seconds, back-light LCD

Calibration By CAL function (on keypad)

Min. curvature of 40mm diameter (V-grooved base) cylindrical surface

Tracing length 6mm

Tracing speed 1.0mm/sec

Accuracy Conforms to ISO Class 3

Pick-up stylus Piëzo-electric

Tracer tip Diamond, radius 5 µm ±1 µm

Operating temperature 0°C - 40°C

Power 3.6V / Li-ion batteries low battery indication

Charger 6V DC

Dimensions 110mm x 70mm x 24mm

Weight 200gr

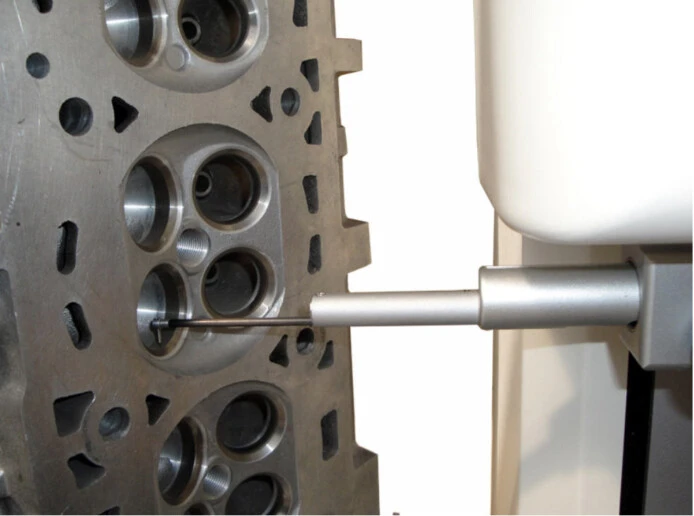

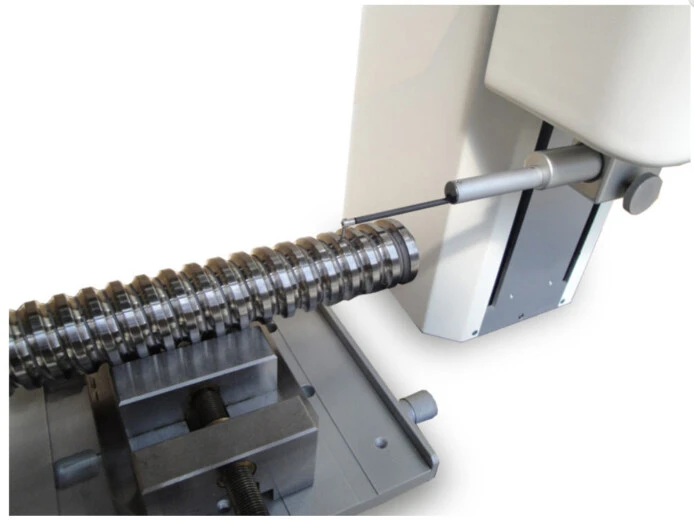

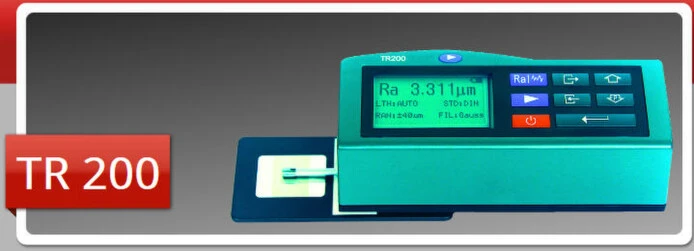

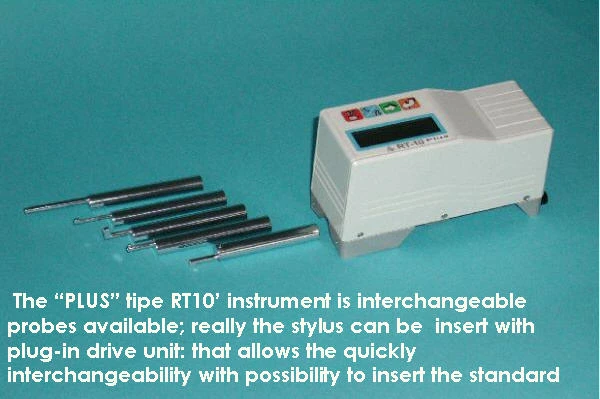

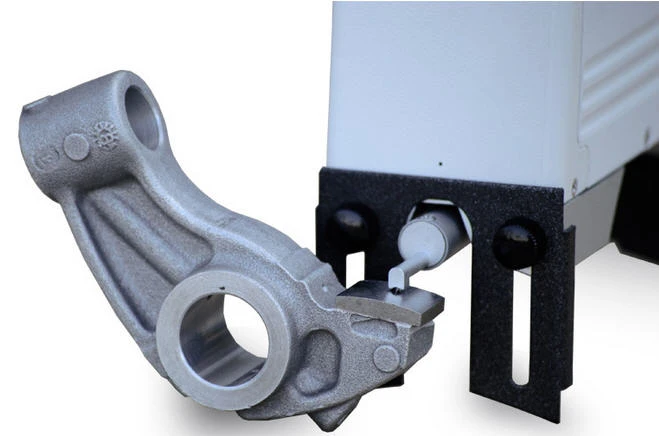

The portable RT-10 PLUS palmtop roughness tester, permits the evaluation of the most important roughness parameters directly on the production site, offering, in a compact package, the advantages of being easy to carry, simple to use and reliability of measurement.

Designed for use on the shop floor, it is shielded against external agents by a special protective membrane. It may measure in difficult positions, including when held in the hand, in the vertical traverse position.

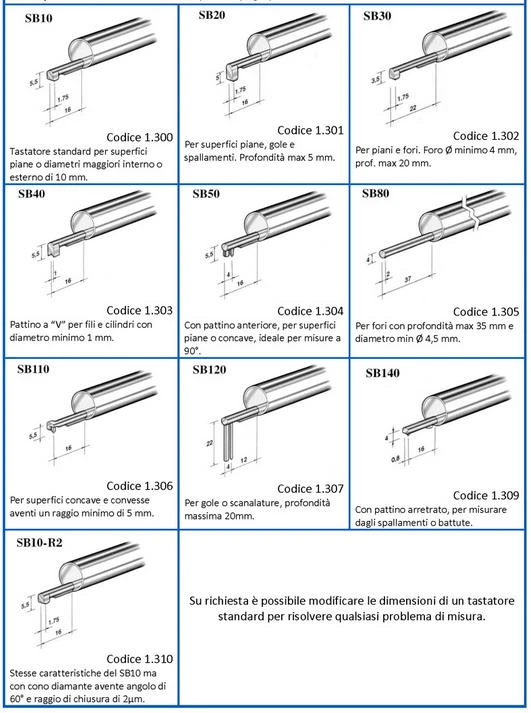

The RT10 Plus (code 1.101) roughness tester features a plug-in connector that allows to

interchange the pick-up, thus being able to take measurements on all

types of surfaces, by simply mounting the most suitable pick-up.

| Measurement range: | ±200 μm |

| Resolution: | 0,001 μm |

| Cut-off lenght: | 0,25 – 0,8 - 2,5 mm |

| Cut-off number: | Selectable from 1 to 5 |

Traverse lenght : | Up to 16 mm |

| Pick-up: | Inductive, it can be rotated of 90° for lateral measurements |

Measurement parameters: | 11 parameters (Ra, Rq, Rt, Rz, Rc, RSm, Rmr- Pt, R, AR, Rx) |

| Measurement range: | ±300μm |

| Resolution: | 0,001 μm |

| Cut-off Lenght: | 0,25 – 0,8 - 2,5 mm |

| Cut-off number: | Selectable from 1 to 5 |

| Traverse lenght: | Up to 16 mm |

| Pick-up: | Inductive, it can be rotated of 90° for lateral measurements |

| Measurement parameters: | 31 parameters (Ra, Rq, Rt, Rz, Rp, Rc, Rv, Rsm, Rdc, Pa, Pq, Pt, Pp, Pc, Pv, Psm, RPc, PPc – Rk, Rpk, Pvk, Mr1, Mr2 – Pt, R, Rx, AR-R3, R3zm, Rmax) |

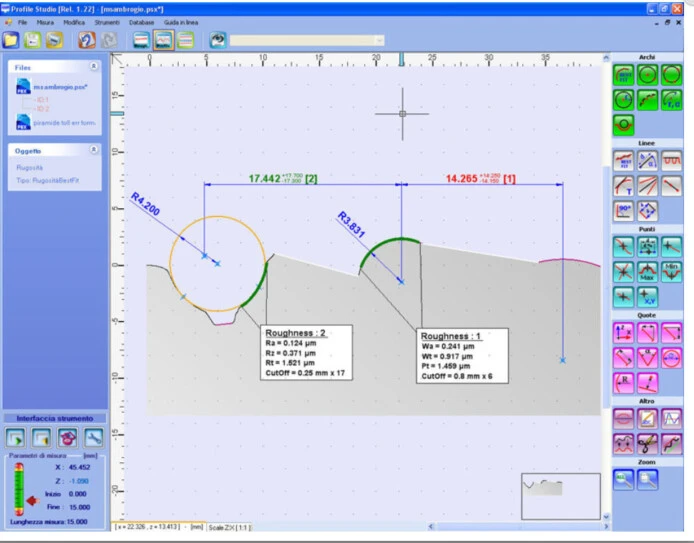

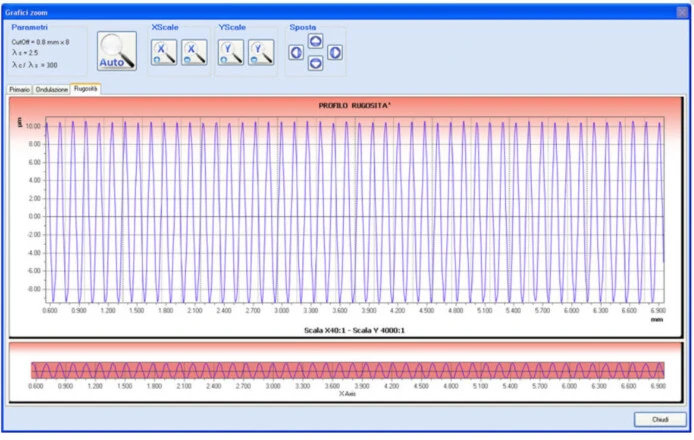

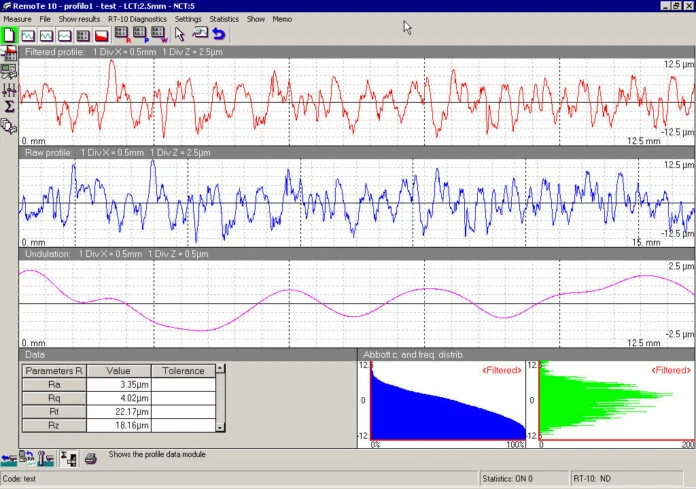

| Parameters calculated: | |

| ISO 4287:09 | Rp, Rt, Rv, Rc, Rz, Rzjis, Ra, Ra75, RSm, RΔq, Rsk, Rku, Rδc, RPc, RmrRel Wp, Wt, Wv, Wc, Wz, Wa, Wq, WSm, WΔq, Wsk, Wku, Wδc, WPc, WmrRel Pp, Pt, Pv, Pc, Pz, Pa, Pq, PΔSm, Pq, Psk, Pku, Pδc, PPc, PmeRel |

| ISO 13565:96 | Rk, Rpk, Rvk, Mr1, Mr2, A1, A2 |

| DIN 4768:90 | Ry5, Rmax, R3z, R3zMax, PtDIN |

| ISO12085:98 | Pt, R, AR, Rx, Wte, W, AW, Wx, Rke, Rpke, Rvke |

| VDA 2007 | WD, WDc, WDt, WDSm |

| Measurement range in X: | 0.15 mm– 120 mm |

| Measurement range in Z: | 3 mm o 5 mm |

| Resolution in X: | 0.1 μm |

| Resolution in Z: | 0.1 nm |