Machu-Test-Bath

Coatings & Industry > CORROSION > Humidity chamber

Machu Tests

Machu-Test-Bath, Model 530

Qualicoat

The container with lid is made of polypropylen, with an integrated small container with grooved base for setting up samples, equipped with a thermostat and a circulating pump.

The Machu-Test-Bath, Model 530, is developed for short-term immersion corrosion tests. The test is made in a warm and acidic test solution at a temperature of 37 °C for a duration of 48 h.

The Machu test is an accelerated salt spray test.

It's an excellent screening tool for quick evaluation of coating products, specially developped for research and developpment, and customer service.

24 hours test duration is equivalent to 500 hours salt spray.

48 hours test duration is equivalent to 1.000 hours salt spray.

The Machu test gives you the opportunity to evaluate the weathering performance of powder coating system. Pigments fading, film haziness, loss of gloss and film softening after 48-96 hurs test duration.

A simply wat to point out outdoor durability problems.

The test solution consists of natrium chloride, acetic acid and hydrogen peroxide. After a test period of 24 h the test solution has to be renewed and the pH value corrected by using hydrogen peroxide.

The Machu test is used to obtain the QUALICOAT label and works according to the requirements of QIB (Quality Community for Industrial Coating).

The Machu-Test-Bath container with top cover is made of Polypropylen, and is equipped with a thermometer and circulation pump.

Because of the aggressive test solution a smaller container is integrated to place the test panels inside. The bottom of the test container is equipped with slots to place the test panels with an angle of 15° or 20°.

Qualicoat recommends :

"Before immersion, a cross-cut incision with a width of 1 mm shall be made on the significant surface with a special tool to cut the coating down to the metal. If the dimensions of the sample are smaller than 70 x 70 mm, one scratch will be made lengthwise."

"Accelerated corrosion test, on extruded sections of AA 6060 or AA 6063 only"

The test panels need to be scratched crosswise with a 1 mm cutting tool through the coating to the metal by a scratching tool. We recommend our Scratching Tool according to Sikkens, Model 463.

Technical Data

Dimensions: Bath-Container approx. 540 x 400 x 260 mm

Test-Container approx.. 350 x 300 x 240 mm

Weight (net): approx. 18 kg

Temperature: 37 °C +/- 1 °C

Test duration: 48 h +/- 0,5 h

Power supply: 230 VAC

REF : 101-530.01.51 Machu-Test-Bath, Model 530

Accessory

Cutting tools :

REF : 101-0100.01.31 Scratch Stylus acc. to Sikkens, Erichsen Model 463 for the application of cross-cuts

Samples :

REF : 206-6060 63-1 Aluminium test panels AA6060/6063 (150x70x0,8 mm) 100 pces

REF : 206-6060 63-1/S Aluminium test panels AA6060/6063 (70x70x0,8 mm) 100 pces

Also available per 200, 300 and 400 units

Machu Tests Stainless Steel Thank

Baths model SPL and Gbath1800 particularly indicated for Machu Tests

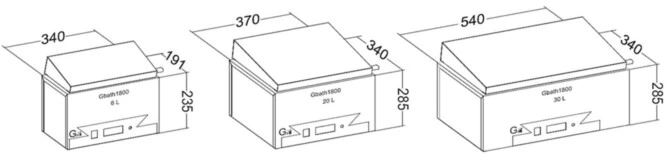

GBath 1800 Laboratory Thermostatic Bath AGS SMART +95,0°C

* Stainless Steel Tank, AISI 304 with rounded corners* Eco-friendly Insulation, high energy saving* Stainless Steel External Structure, AISI 304* Non-Slip Rubber Feet* Drain Tap* Predisposed for the addition of Gable Cover with Hinges (OPTION)* Main Green Switch* Bipolar Fuses

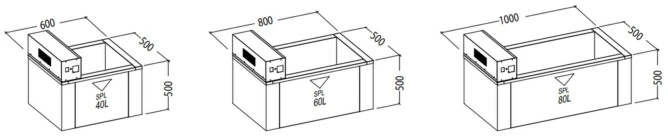

SPL Thermo baths

SPL Large Capacity Thermostatic Bath +100,0°C

- Stainless Steel Tank, AISI 304, TIG-welded

- Stainless Steel AISI 304 External Structure

- Bipolar Main Green Switch

- Motorized Stirrer with Deflectors and False Bottom

- Armored heating resistors

- Drain Tap

- Independent Safety Thermostat