Metal Testing > Sheet Metal Testing > Model 126 Plus

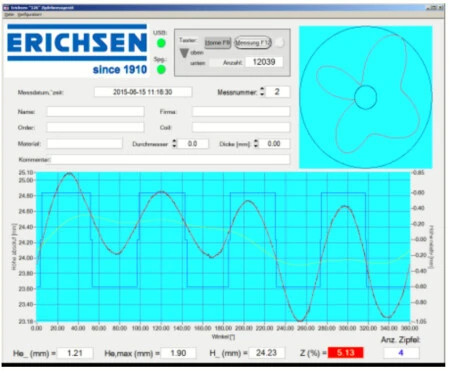

Sheet Metal Testing : Ear Measuring Instrument Model 126 Plus

Ear measuring instrument, Measuring of Deep-Drawn Cups, for cups of 15 – 50 mm diameter, max. 100 mm cup height

The Model 126 Plus ear measuring instrument consists of a turntable and a vertical gauge head with a roller.

By a jaw chuck, the cup is centered and fixed.

The gauge head can be positioned to different cups heights and diameters. While revolving around its own axis, the gauge head is measuring the shape of the cup’s edge.

This waveform of the cup’s edge is called earring.

Technical data:

Cup diameter: 15-50 mm (other diameters on request)

Cup height: 12-100 mm

Centering and fixing: Jaw chuck

Measurement values per revolution: >5000

Sensing device: M2,5 roller

Measurement force: approx. 2,5 N

Measurement stroke: 50 mm

Sensor resolution: 0,00005 mm

Sensor accuracy: ±0,0001 mm

Display accuracy: 0,02 mm

Indicated digits: 0,01 mm

Time per measurement process: approx. 15 s