LINEARTESTER 249 Smart

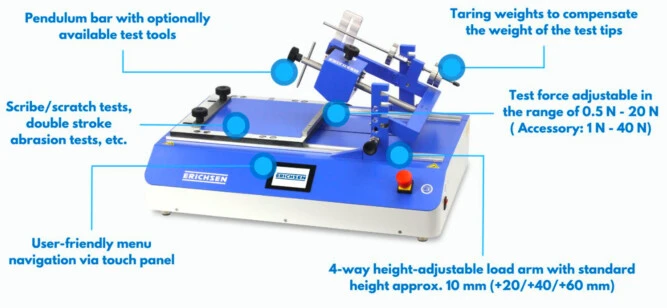

- Scribe/Scratch tests;

- To and fro-cycle abrasion tests;

- Crockmeter tests;

- MEK tests;

- tests determining the resistance against solvents in general or wipe test, respectively.

Principle of the Test

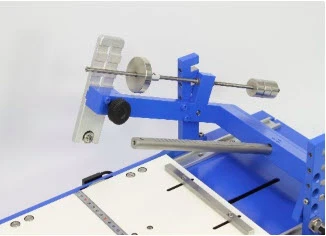

The test panel can be moved sideways so that a series of scratches can be carried out side by side with different force settings.

When testing insulating coatings on conducting substrates, an electric recognition of the throughscratching offers an additional security for setting the scratching force.

For abrasion tests, crockmeter tests, MEK or wipe tests the test movement is carried out with the tool lowered onto the specimen, in preset cycles to and fro.

We introduce two advancements for precise and efficient cross hatch cutting:

The SledCutter 295 XVII elevates manual cross hatch cutting to a new level.

The Multi-Cut Adapter enhances the functionality of our LINEARTESTER 249 Smart, enabling precise, right-angled cross-cut patterns with adjustable cutting forces from 2 to 40 N. This guarantees consistently accurate cuts, revealing the substrate clearly.

Both devices contribute to making your testing processes more efficient and accurate

Spherical inserts for the clamping adapter (short shaft without clamping device)

Test tip acc. to van Laar (Ø 0.5 mm)

Test tip acc. to Bosch (Ø 0.75 mm)

Test tip acc. to ISO (Ø 1.0 mm)

Test tip acc. to ISO (Ø 1.0 mm) – additionally covered with an extremly hard layer

Test tip acc. to BMW (Ø 3.0 mm)

Asymmetric inserts (short shaft with clamping device)

Test tip acc. to Clemen (R 1.0 mm)

Test Tip for cross hatch cutting (30°) – additionally covered with an extremly hard layer

Inserts (Ø 16 mm/R 0.5 mm) for the disc adapter

Test discs made of Duroplast (p. 10 pcs.)

Test discs made of copper (p. 10 pcs.)

Test discs made of stainless steel (p. 10 pcs.)

Test discs made of stainless steel, additionally covered with an extremly hard layer (p. 10 pcs.)

Adapter for abrasion tests

Squarish adapter (egde length 25 mm)

Cylindrical adapter (dia. 25 mm)

Accessories

Test Tip with long shaft

Test tip acc. to Clemen (R 1.0 mm)

Test tip acc. to van Laar (Ø 0.5 mm)

Test tip acc. to IHD (Ø 0.6 mm)

Test tip acc. to ISO (Ø 1.0 mm)

Test tip acc. to VW (3 mm/60°)

Test tip acc. to (0.5 mm/90°)

Test tip acc. to (1.0 mm/90°)

Equipment for MEK test

MEK-Attachment

Test plugs made of high dense special felt (per 100 pcs.)

Equipment for Crockmeter test

Test set for MEK test

Crocking cloth (per 1000 pcs.)

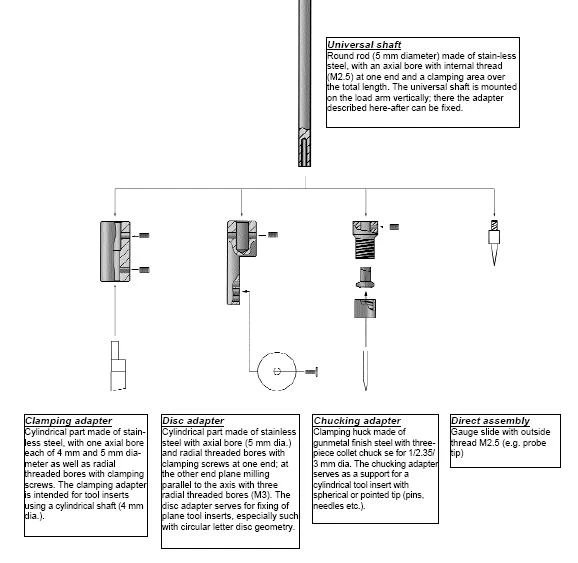

Universal adapter set and accessories

Universal Adapter Set