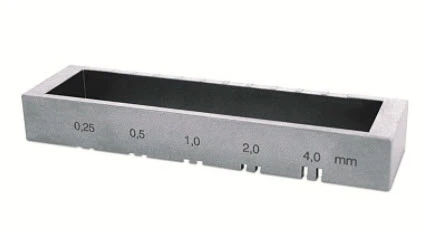

Model 419-ASTM

Using a film-applicator frame made of stainless steel, the parallel wet film strips are applied to a substrate at different gap heights.

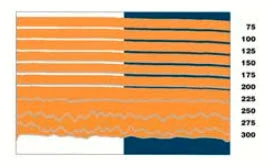

The drainage slope is determined visually when the sample is in a vertical position, and the tendency to flow when the sample is horizontal after curing.

Gaps are ground into two of the applicator edges of the film-applicator frame.

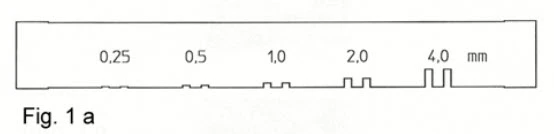

1. The applicator edge for the flow test has 5 pairs of gaps. The gap widths, distances within a double gap, and the distance between the gap pairs are defined and do not vary. The gap heights vary in the range of 250 microns to 4 mm, graduated in doubled steps,

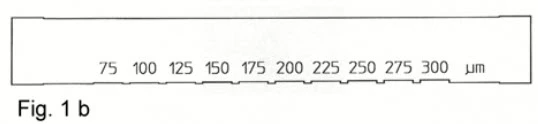

2. The applicator edge for the drainage test has 10 gaps of increasing height. They range from 75 μm to 300 μm, graduated in 25 μm increments.

After the product has been spread, the contrast chart is immediately placed in vertical position, with the thinnest film at the top. The thickness at which the strips join indicates the tendency to sagging.

Testing principle

Parallel strips of wet film are applied to a substrate using a special paint applicator frame made of stainless steel and featuring slots of

various heights.

The sag tendency is determined in a vertical flow test, the levelling tendency is ascertained when the specimen is horizontal. The specimen

panel is examined visually after the coating has hardened.

Technical specifications

Width : 115 mm

Gap Height/ Coat Thickness : 75 µm -1.3 mm

Levelling and Sag Tester, Model 419-ASTM

Design and function

Slots are cut into two sides of the film applicator frame:

• The drawing blade for the levelling test features 5 pairs of slots (see fig. 1a). The slot widths, the span of each slot and the distance between the pairs of slots are predefined.

The heights of the individual pairs of slots are graded in doubling steps ranging from 250 µm to 4 mm.

• The drawing blade for the sag test features 10 slots (see fig. 1b) which are graded in 25µm steps, increasing from 75 µm to 300 µm.

Levelling test according to ASTM D 2801 1)

The wet film strips are applied to a predefined substrate using the doctor blade for levelling tests.

After the specimen has hardened in the horizontal position, the number of double strips which have merged with each other is established.

1) This standard was withdrawn in 1990

Sagging test according to ASTM D 4400

Method A

The strips of wet film are applied to a black-and white contrast card using the doctor blade of the applicator for sag tests (application rate approx. 150mm/s).

Immediately after application, the card is positioned vertically in such a way that the strips of film are horizontal, with the thinnest strip at the top.

After hardening, the level is determined which has not quite spread to the strip below.

Further evaluation details are described in ASTM D 4400, Procedure A.

Method B

The strips of wet film are applied to a contrast card (2) as described in method A.

Prior to application, however, two marking lines are drawn on the carton at right angles to the direction of application. 15 seconds after application the specimen is placed in a vertical position in such a way that the strips of film are vertical and the reference markings are horizontal.

After hardening, the level is determined at which a shift of marking is just recognizable in relation to the original reference line.

A detailed description is given in ASTM D 4400, Procedure B.

(2) Contrast cards, model 451, are suitable for this purpose.

Model 419-DIN Specifications

Dimensions: 115 x 30 x 15 mm

Net weight: approx. 0.12 kg

Thickness of drawing blade: 5 mm

Slot heights:

- 75 µm - 300 µm (in 25-µm steps)

- 350 µm - 700 µm (in 50-µm steps)

- 800 µm - 1300 µm (in 100-µm steps)

Slot width: 10 mm

Distance between slots: 2 mm

Ordering Information

REF. Product Name

101-0053.01.31 Levelling and Sag Tester Model 419-ASTM, incl. case

101-0229.01.31 Sag Tester Model 419-DIN incl. case