FLow Cups

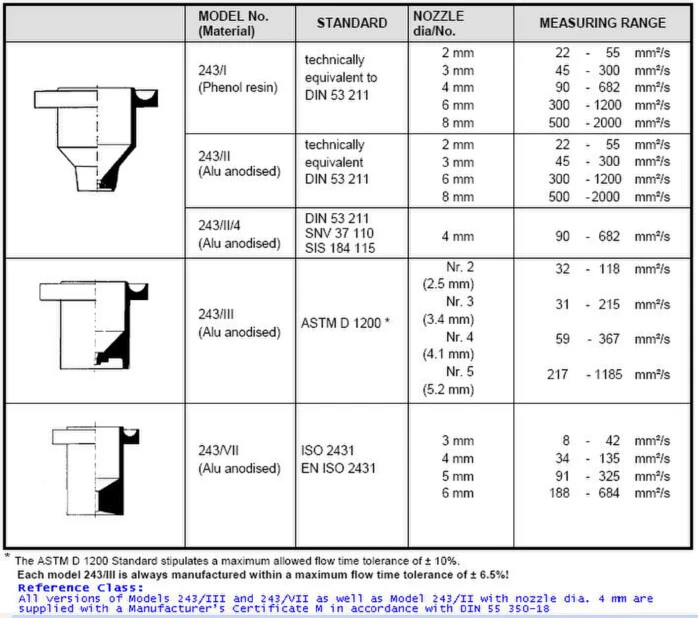

VISCOSITY CUPS, Models 243

Very easy to use instruments in anodized aluminium with a stainless steel orifice, for measuring the consistency of paints, varnishes and similar products.

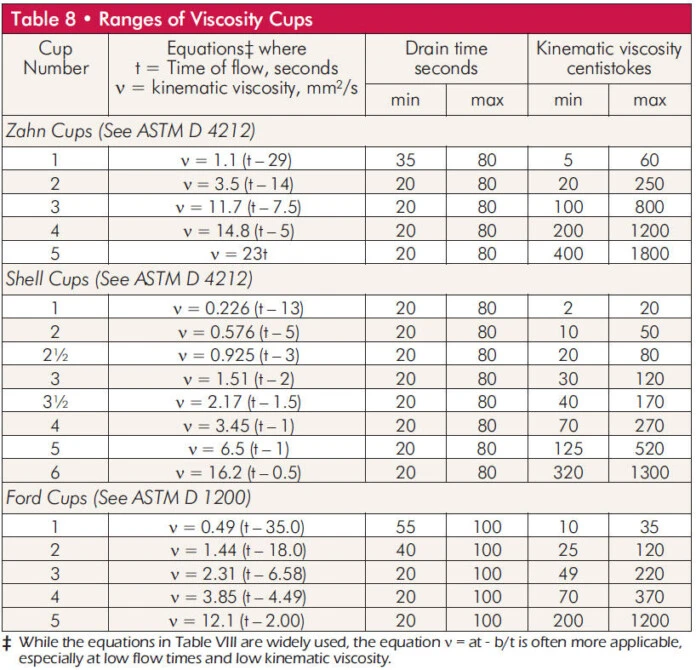

The measured kinematic viscosity is generally expressed in seconds (s) flow time, which can be converted to centistokes (cSt).

The cups can be supplied separately or on an adjustable stand, including a precision level and an overflow glass plate.

The stand can be supplied with a flow jacket for temperature control.

Several capacities are available, according to standards; from 5 to 5000 cSt.

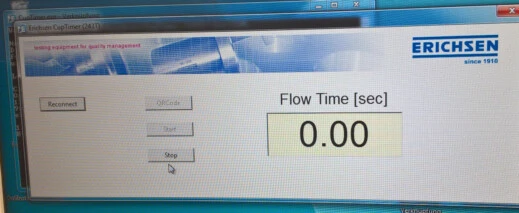

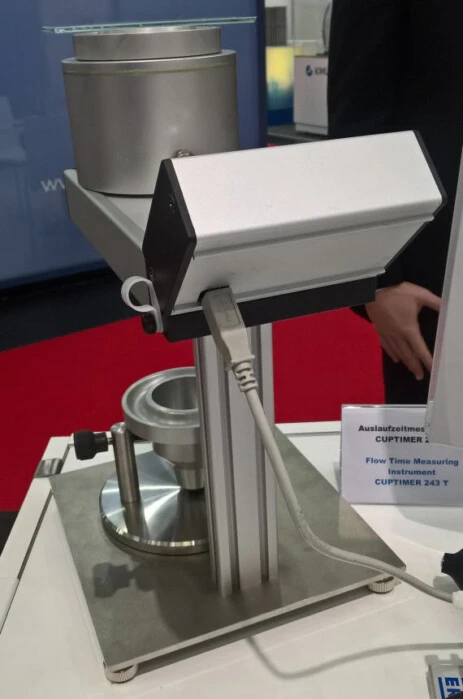

Flow Time Measuring Instrument CUPTIMER 243 T

This opto-electronic measuring instrument offers a number of advantages to the user.

. Automatic measuring sequence with optical detection of the stream of sample.

. Flow times up to 1000 s can be read off from the LC display with a resolution up to 0.01 s.

. Equally suitable for all liquids (transparent calibration oils and opaque lacquers).

. Practical temperature adjustment: Temperature jacket removable from the basic unit; with adaptors for different shapes of flow cups.

. Easy to handle: One-button-operation.

. Designed as a mobile measuring station: sturdy, compact stand construction mounted on an adjustable base; plug-type tube connections; operated via plug-in supply unit.

Two models are available : one Flow Time Measuring Instrument CUPTIMER 243 T with temperature jacket, and one without temperature jacket.

Specially designed for the demanding technician working with toxic liquids.

For his comfort no hand contact with the measured product ; and the assurance of an excellent reproducibility.

Orifice diameter No. 4 (4.1 mm)

Viscosity Range : 31-215 mm²/s Viscosity Range :

Material : anodised aluminium, nozzles of stainless steel

Orifice diameter No. 3 (3.4 mm)

Viscosity Range : 31-215 mm²/s

Material : anodised aluminium, nozzles of stainless steel

Orifice diameter 2 mm

Viscosity Range : 101-

Material : anodised aluminium, nozzles of stainless steel

Orifice diameter 6 mm

Viscosity Range : 101-

Material : anodised aluminium, nozzles of stainless steel

Orifice diameter 4 mm

Viscosity Range : 90 - 682 mm²/s

Material : anodised aluminium, nozzles of stainless steel

Orifice diameter 4 mm

Viscosity Range : 90 - 682 mm²/s

Material : anodised aluminium, nozzles of stainless steel

Flow Time Measuring Instrument CUPTIMER 243 T “REFERENCE CLASS”

Mobile measuring station for exact determination of the flow time (incl. temperature jacket, adapters for ISO, ASTM and DIN flow cups, filling support stand, glass plate, spirit level and plug-in supply unit)

Flow Time Measuring Instrument CUPTIMER 243 T “REFERENCE CLASS” as Ord.-No. 0177.01.31, but without temperature, jacket, filling support stand, glass plate

Nozzle Dia. : 3 mm

Viscosity Range : 10 - 40 mm²/s

Material : Aluminium alloy

Nozzle Dia. : 6 mm

Viscosity Range : 190 - 680 mm²/s

Material : Aluminium alloy

Nozzle Dia. : 5 mm

Viscosity Range : 90 - 330 mm²/s

Material : Aluminium alloy

Nozzle Dia. : 4 mm

Viscosity Range : 35 - 135 mm²/s

Material : Aluminium alloy

Orifice diameter No. 5 (5.2 mm)

Viscosity Range : 31-215 mm²/s

Material : anodised aluminium, nozzles of stainless steel

Orifice diameter No. 2 (2.5 mm)

Viscosity Range : 32-118 mm²/s

Material : anodised aluminium, nozzles of stainless steel

Nozzle Dia. : 6 mm

Viscosity Range : 188 - 684 mm²/s

Material : anodised aluminium, stainless steel nozzle

Nozzle Dia. : 3 mm

Viscosity Range : 8 - 42 mm²/s

Material : anodised aluminium, stainless steel nozzle

Nozzle Dia. : 3 mm

Viscosity Range : 8 - 42 mm²/s

Material : anodised aluminium, stainless steel nozzle

Nozzle Dia. : 4 mm

Viscosity Range : 34 - 135 mm²/s

Material : anodised aluminium, stainless steel nozzle

Nozzle Dia. : 6 mm

Viscosity Range : 188 - 684 mm²/s

Material : anodised aluminium, stainless steel nozzle

Nozzle Dia. : 5 mm

Viscosity Range : 91 - 325 mm²/s

Material : anodised aluminium, stainless steel nozzle

Nozzle Dia. : 4 mm

Viscosity Range : 34 - 135 mm²/s

Material : anodised aluminium, stainless steel nozzle

Nozzle Dia. : 5 mm

Viscosity Range : 91 - 325 mm²/s

Material : anodised aluminium, stainless steel nozzle

Orifice diameter 3 mm

Viscosity Range : 45 - 300 mm²/s

Material : Phenol resin with stainless steel nozzle

Orifice diameter 4 mm

Viscosity Range : 90 - 682 mm²/s

Material : Phenol resin with stainless steel nozzle

Orifice diameter 6 mm

Viscosity Range : 300 - 1200 mm²/s

Material : Phenol resin with stainless steel nozzle

Orifice diameter 8 mm

Viscosity Range : 500 - 2000 mm²/s

Material : Phenol resin with stainless steel nozzle

Orifice diameter 2 mm

Viscosity Range : 22 - 55 mm²/s

Material : Phenol resin with stainless steel nozzle

Orifice diameter 3 mm

Viscosity Range : 101-

Material : anodised aluminium, nozzles of stainless steel

Orifice diameter 8 mm

Viscosity Range : 101-

Material : anodised aluminium, nozzles of stainless steel

Nozzle Dia. : 6 mm

Viscosity Range : 300 - 1,500 mm²/s

Material : Aluminium alloy

Nozzle Dia. : 2 mm

Viscosity Range : 10 - 50 mm²/s

Material : Aluminium alloy

Nozzle Dia. : 4 mm

Viscosity Range : 50 - 800 mm²/s

Material : Aluminium alloy

Nozzle Dia. : 3 mm

Viscosity Range : 30 - 300 mm²/s

Material : Aluminium alloy

Nozzle Dia. : No. 1 (0.078")

Viscosity Range : 5 - 60 mm²/s

Material : Aluminium alloy

Nozzle Dia. : No. 3 (0.148")

Viscosity Range : 100 - 800 mm²/s

Material : Aluminium alloy

Nozzle Dia. : No. 5 (0.207")

Viscosity Range : 400 - 1,800 mm²/s

Material : Aluminium alloy

Nozzle Dia. : No. 4 (0.168")

Viscosity Range : 200 - 1,200 mm²/s

Material : Aluminium alloy

Nozzle Dia. : No. 2 (0.108")

Viscosity Range : 20 - 250 mm²/s

Material : Aluminium alloy

T° scale from 0 to 50°C

Reading accuracy 0.2°C,

Suitable for all models 243/I to 243/VII

Simple consistency test.

The Visco Test Blade is designed for the rapid determination of the viscosity of paints for spray and brush application. On the one hand it is a practical stirring utensil when adding thinner to the paint and, on the other hand, it serves as a device to measure the viscosity of the substance. It is easy to use and to clean, making it a convenient instrument for use in the practice.

The Visco Test Blade is immersed into the test liquid in such a way that the slit is entirely covered, whilst the upper hole remains free. The blade is then lifted quickly out of the liquid, holding it upright, and the time measured until the fluid meniscus in the slit reaches the lower hole. This point is clearly visible since the membrane covering the hole will burst at that moment. The run-off speed in the slit is also influenced by the run-off speed on the remainder of the blade. The immersion depth should therefore be adhered to exactly. Properly wetted the blade prior to the test.

The Nomogram Disk 458 is designed for the conversion of viscosity measurement data in various unitary systems which have a specified reference temperature within any one unitary system.

• The VISCOSITY NOMOGRAM makes it possible to convert viscosity data into the following units reference temperatures between 15°C and 25°C):

• cSt = mm²s-¹

• cP = mPa s

• Engler degrees

• Krebs Stormer units

• Gardner Holdt units

• Efflux times

- ISO 2431 (4 mm)

- ASTM D 1200 (Ford No. 3, No. 4)

- DIN 53 211

The TEMPERATURE-DEPENDENT VISCOSITY SCALE is used for converting viscosity data for reference temperatures in the range between 5°C and 30°C.

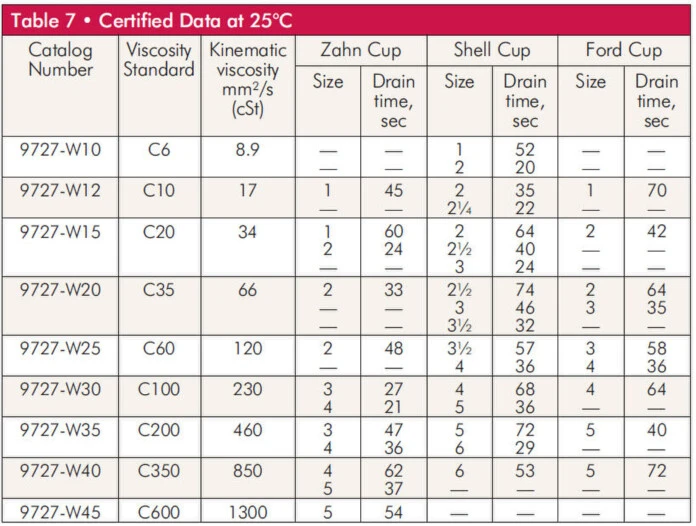

WINDOWS® based software 1 licence (disc)

This software which has been specifically developed to enable rapid conversions between viscosity and efflux times for standardized flow cups.

complete with 5 exchangeable cups of orifice diameter No. 1 (0.078"), No. 2 (0.108"), No. 3 (0.148"), No. 4 (0.168") and No. 5 (0.207"), including carrying case