3D topography

Coatings & Industry > Surface inspection

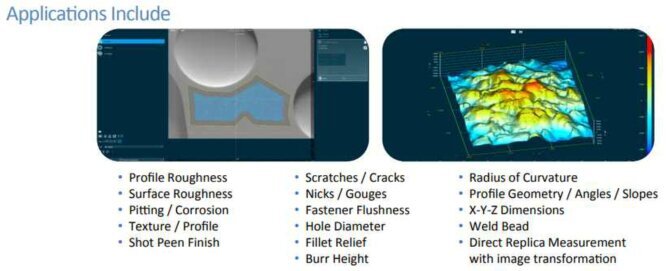

Improve productivity and lower cost across a wide range of NDT workflows:

• Incoming Inspection and Vendor Qualification• Production Quality Control• Field Installation and Flight Line• MRO (Maintenance, Repair, and Overhaul), and Sustainment• Research & DevelopmentThe GelSight Max 3D surface analysis system transforms workflows by putting lab-grade surface measurements in the palm of your hand, with fully traceable, digital results in seconds.• Academia

For use in hard-to-reach areas, the Replica Transformation feature enables direct, in-situ measurements of metrology-grade replica materials

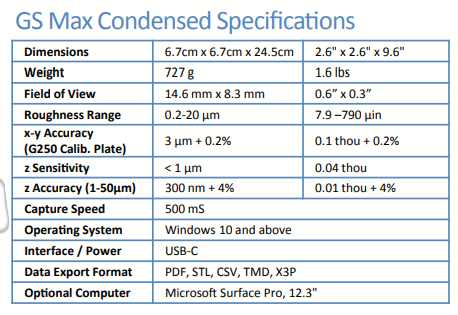

The GelSight Max is our highest resolution handheld surface analysis solution and designed for the most demanding applications, including surface and profile roughness from 0.2 to 20 µm.

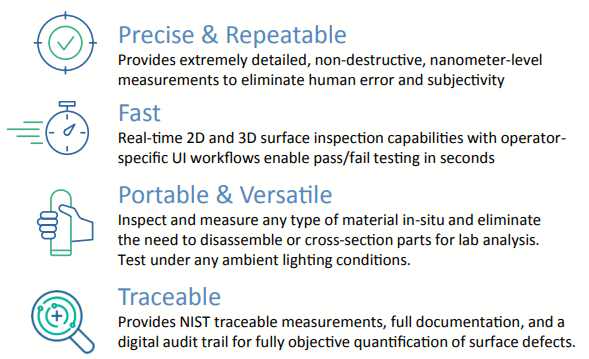

The GelSight Max immediately quantifies the surface characteristics of any material at any workflow location, regardless of composition, reflectivity, transparency, or ambient lighting conditions. Its precise, repeatable, in-situ measurement capability can save tens of thousands and/or man-hours per year in unnecessary scrap, re-work, down-time, or poor yields by eliminating false failures and boosting productivity.

Handheld, nanometer scale surface measurements in seconds

The GelSight Max is our highest resolution handheld 3D surface analysis solution and is designed for the most demanding applications, with nanometer scale zaxis accuracy and a surface roughness range from 0.2 to 20 µm Ra.

The GelSight Max immediately quantifies the surface characteristics of any material at any workflow location, regardless of composition, reflectivity, transparency, or ambient lighting conditions.

Its precise, repeatable, in-situ measurement capability can lower the cost-per-measurement by 10x or more vs. legacy solutions while eliminating test escapes and boosting workflow productivity.

Industry 4.0 ready

Including an AI Toolbox Automated, high-speed process workflows are enabled by a streamlined ‘Operator Mode’ UI, external triggering, customizable functions with unique pass/fail criteria, batch-mode analysis, STL and CSV outputs, and immediate PDF report generation.

In addition, users can create powerful AI models to apply automated touch sensing to many tasks that had no simple path to digitization.

2D and 3D Measurement and Analysis Capabilities

Unlike manual, mechanical, or optical measurement technologies, GelSight’s patented elastomeric sensor technology conforms to the topology of any surface regardless of material, reflectivity, transparency, or ambient lighting conditions. 2D surface detail is displayed in real time, and micron-level 3D measurement and analysis of surface textures and defects are computed and displayed in seconds.

GS Mobile includes a powerful suite of 2D and 3D tools for surface characterization.

Our BASE software package has a focus on the image itself typically for use in applications where a field portable SEM-like image is desired.

GS Mobile CORE is for users looking to either export their 3D data or focused on scratch and offset measurement.

Our fully featured GS Mobile PRO software offers many tools including the ability to measure profile and surface roughness, automatically detect and characterize defects, pitting, small radii and many more.

For hard-to-reach areas, the updated Replica Transformation feature enables intuitive, direct and in-situ measurement of replica material to eliminate the traditional down-time waiting for lab results with GelSight’s fast report creation options streamlining workflows.