Universel

Metal Testing > Hardness Testers > AFFRI > Benchtop > UNIVERSAL HARDNESS TESTER

Universal hardness testers LD250 and LD750

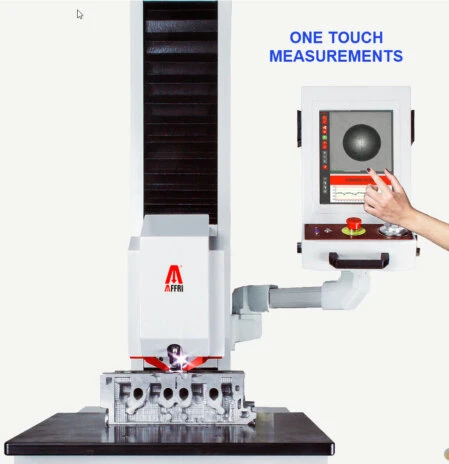

Fully motorized and automatic, the test is not affected by operator influences and can easily be used by operators of every level

Universal hardness testers LD250 and LD750 include all hardness testing methods: Rockwell, Superficial Rockwell, Brinell, Brinell HBT, and Vickers.

Hardness measurements on every metal and alloys conforming to ASTM and DIN EN ISO international standards.

Test loads

- LD250: From 1 to 250 kgf (9,807 to 2452 N).

- LD750: From 3 to 3000 kgf (29.4 to 29421 N)

Rockwell ISO 6508 / ASTM E-18:

HRA – HRB – HRC – HRD – HRF – HRG – HRL – HRM – HRR / HRN – HRT – HRS – HRW – HRX – HRY

Brinell HBW ISO 6506 / ASTM E-10

HBW1/30 – HBW2.5/15.625 – HBW2.5/31.25 – HBW2.5/62.5 – HBW2.5/187.5 – HBW5/25 – HRW5/62,5 – HBW5/125 – HBW5/250 – HBW5/750 – HBW10/100 – HBW10/250 – HBW10/500 – HBW10/1000 – HBW10/1500 – HBW10/3000

Brinell HBWT ASTM E103

HBWT2.5/62.5 – HBWT2.5/187.5 – HBWT5/125 – HBWT5/250 – HBWT5/750 – HBWT10/500 – HBWT10/1000 – HBWT10/1500 – HBWT10/3000

Vickers ISO 6507 / ASTM E-384 / ASTM E-92

HV1 – HV2 – HV3 – HV5 – HV10 – HV20 – HV30 – HV50 – HV100

TECHNICAL SPECIFICATIONS

Standards

EN-ISO 6506-2 / EN-ISO 6507-2 / EN-ISO 6508-2 / EN-ISO 2039 / ISO 868 / ASTM-E10 / ASTM-E18 / ASTM-E103 / ASTM 2240 / ASTM-E384 / JIS

Indenter stroke

Motorized 30 mm / 1.2" with automatic contact

Height Capacity

LD750: Motorized 720mm / 28″ (more on request)

LD250: Motorized 390mm / 15″ (more on request)

LD250: Motorized 390mm / 15″ (more on request)

Depth Capacity

D750: 265 mm / 10.5” (more on request)

LD250: 190 mm / 7.5” (more on request)

LD250: 190 mm / 7.5” (more on request)

Working table:

LD750: 480 x 675 mm / 19 x 26 “ (more on request)

LD250: 330 x 390 mm / 13 x 15.5 “ (more on request)

LD250: 330 x 390 mm / 13 x 15.5 “ (more on request)

Preload

29.4 - 98.1 N (3 - 10 kgf)

Force range*** Depending on the models***:

Rockwell:

Rockwell:

588.4 - 980.7 - 1471 N (60 - 100 - 150 kgf)

Superficial Rockwell:

Superficial Rockwell:

147.1 - 294.2 - 441.3 N (15 - 30 - 45 kgf)

Brinell:

Brinell:

9.807 - 24.52 - 49.03 - 61.29 - 98.07 - 153.2 - 245.2 - 294.2 - 306.5 - 612.9 - 1226 - 1839 - 2452 - 4903 - 7355 - 9870 - 14710 - 29421N

(1 - 2.5 - 5 - 6.25 - 10 - 15.625 - 25 - 30 - 31.2 - 62.5 - 125 - 187.5 - 250 - 500 - 750 - 1000 - 1500 - 3000kgf)

Vickers - Knoop:

(1 - 2.5 - 5 - 6.25 - 10 - 15.625 - 25 - 30 - 31.2 - 62.5 - 125 - 187.5 - 250 - 500 - 750 - 1000 - 1500 - 3000kgf)

Vickers - Knoop:

9.807 - 29.42 - 49.03 - 98.07 - 147.1 - 196 - 294.2 - 490.35 - 980.7 N (1 - 3 - 5 - 10 - 15 - 20 - 30 - 50 - 100 kgf)

Optional tests:

Optional tests:

49 - 132 - 358 - 961 N (For plastics and rubbers as per EN-ISO 2039 std)

Shore A - D

Shore A - D

Feasible tests***Depending on the models***:

Rockwell:

Rockwell:

HRA - HRB - HRC - HRD - HRE - HRF - HRG - HRH - HRK - HRL - HRM - HRP - HRR - HRS - HRV

Superficiale Rockwell:

Superficiale Rockwell:

HR15N/T/S/W/X/Y - HR30N/T/S/W/X/Y - HR45N/T/S/W/X/Y

Brinell

Brinell

HBW: HBW 1/1 – HBW 1/1.25 – HBW 1/2.5 – HBW 1/5 – HBW 1/30 – HBW 2.5/6.25 – HBW 2.5/7.8125 - HBW 2.5/15.625 – HBW 2.5/31.25 – HBW 2.5/62.5 – HBW 2.5/187.5 – HBW 5/25 – HBW 5/31.25 – HBW 5/62.5 – HBW 5/125 – HBW 5/250 – HBW 5/750 – HBW 10/100 – HBW 10/125 – HBW 10/250 – HBW 10/500 – HBW 10/1000 – HBW 10/1500 – HBW 10/3000

Brinell HBWT:

Brinell HBWT:

1/30 - 2.5/15.6 - 2.5/31.5 - 5/125(3) (Aluminum and alloys) - 2.5/62.5(2) (Aluminum and alloys) - 2.5/187.5(6) (Aluminum and alloys) - 2.5/187.5(5) (Carbon steel) - 2.5/187.5(1) (Cast iron) - 5/125 - 5/250 - 5/750 - 10/500 - 10/1000 - 10/1500 - 10/3000

Vickers - Knoop:

Vickers - Knoop:

HV1 - HV3 - HV5 - HV10 - HV15 - HV20 - HV30 - HV50 - HV100

Shore A - D

Shore A - D

Load accuracy

Better than 0.1%

SERIE VRS

Universal hardness tester for micro/macro Vickers, Knoop, Rockwell, Superficial Rockwell, Brinell and Shore test methods, in compliance with ASTM and ISO hardness standards.

VRS Series are top level bench hardness testers for tough or lab applications.

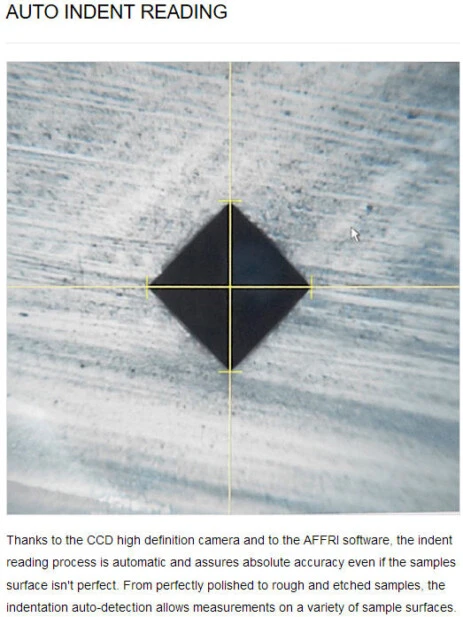

Fully motorized for fully automatic test cycles, with Vickers and Knoop indentation autoreading through a CCD high resolution camera and the relative software.

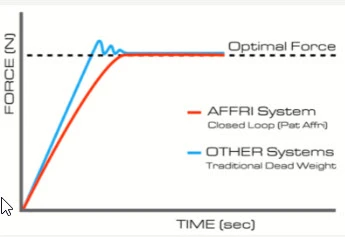

Absolute accuracy (better than 0.5 %) in every condition.

Load forces are applied through load cells and electronically controlled in Closed Loop (Pat. Affri).

Exact hardness result on the first test and R&R data are at the top of its class.

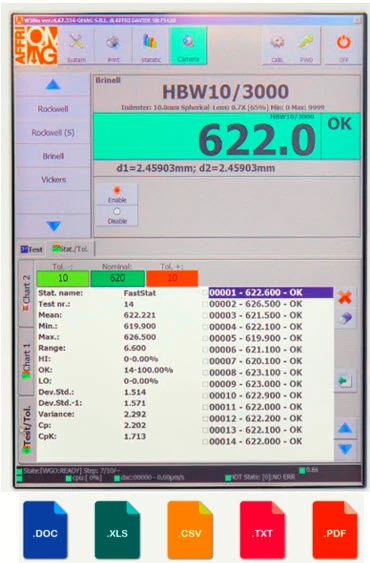

Digital durometers with LCD screen, user friendly interface, real time statistics and graphs and large archive storage.

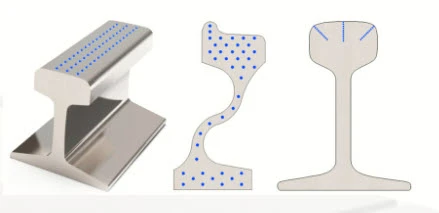

Hardness tests on all metals: Iron, steel, tempered steel, cast iron, brass, aluminum, copper and metal alloys.

Heat treatment, hardening, nitriding, cementation and hardfacing. Hard and soft plastics. Knoop test on ceramic and glass materials.

Test loads:from 0.3 to 250 kgf (From 2.940 to 2452 N)

251 VRSTV/VRSD/VRSA | 270 VRSTV/VRSD/VRSA | 770 VRSTV/VRSD/VRSA | |

Standards | EN-ISO 6506-2 / EN-ISO 6507-2 / EN-ISO 6508-2 / EN-ISO 2039 / EN-ISO 868 / ASTM E-18 / ASTM E-10 / ASTM E-2240 / ASTM E-348 | ||

X-Y Table | ---- | 330x390 mm | |

Vertical head stroke | ---- | 0/380 mm motorized | 0/700 mm motorized (Higher on request) |

| Elevating screw stroke | 0/215 mm | ---- | |

Depth capacity | 190 mm | ||

Reading | VRSTV: Automatic and semi-automatic through CCD camera and software (Computer as optional)

VRSD: Semi-automatic with encoder

VRSA: Semi-automatic with drum scale | ||

| Preload | 29.4 - 98.1 N (3 - 10 kgf) | ||

Test loads | VRSTV/VRSD/VRSA

Vickers - Knoop: 9.807 - 19.60 - 29.42 - 49.03 - 98.07 - 147.1 - 196 -

294.2 - 490.35 - 980.7 N (1 - 2 - 3 - 5 - 10 - 15 - 20 - 30 - 50 - 100

kgf)

Rockwell: 588.4 - 980.7 - 1471 N (60 - 100 - 150 kgf)

Superficial Rockwell: 29.42 - 147.1 - 294.2 - 441.3 N (3 - 15 - 30 - 45 kgf)

Brinell: 61.29 - 98.07 - 153.2 - 245.2 - 294.2 - 306.5 - 612.9 - 1226 - 1839 N (On request 2452 N)

(6.25 - 10 - 15.6 - 25 - 30 - 31.2 - 62.5 - 125 - 187.5 kgf - On request 250 kgf) Optional loads: 49 - 132 - 358 - 961 N (For plastics and rubbers as per EN-ISO 2039 std)

VRSTV-VM/VRSD-VM/VRSA-VM (Micro macro Vickers)

Superficial Rockwell: 29.42 - 147.1 - 294.2 - 441.3 N (3 - 15 - 30 - 45 kgf)

Vickers - Knoop: 2.940 - 4.903 - 9.807 - 19.60 - 24.52 - 29.42 - 49.03 - 98.07 - 147.1 - 196 - 294.2 - 490.35 N (0.3 - 0.5 - 1 - 2 - 2.5 - 3 - 5 - 10 - 15 - 20 - 30 - 50 kgf) | ||

Feasible tests | Rockwell: HRC - HRA - HRD - HRB - HRF - HRG - HRL - HRM - HRR

Superficial Rockwell: HRN - HRT

Brinell: HB30 - HB10 - HB5 - HB2.5 MPa (F/D2)

Vickers - Knoop

Shore A - D | ||

Accuracy | Better than 0,2 % | ||