EDA 300

AFFRI EDA300-MKII

Increase your production quality

Perfect and effective measurements including the first test by checking your products directly during manufacturing. Selective sampling is ineffective. 100% testing of production is possible at a lower price than the price of sampling.

• Conform with standard DIN 50157 - ASTM E110 - B 724

• Accurate rapid and reproduceable results from mesurement of penetration depth and low constant force the most repatable instrument in the world + / - 0,5 HRC

• Indenpence of body dimensions from 0.05 mm thickness can be measuresd

• Direct reasult in 10 different hardness scales and N mm2 sigma range to measure from 10 HRB to 1800 HV

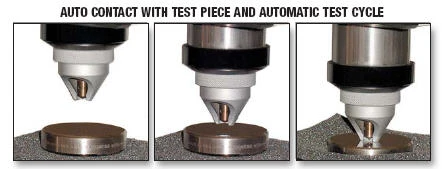

• A single start input to activate without interruption phase: move down head indenter to take the conatct with test surface, clamp sample and execute the test and goes back

• A test is perfomed in only 3 seconds independently from every distance of test sample

• Extreme precision and repeatability also on instable surface,not clean surface, deflective surface also for more 50 mm

• Large free area to support special fixture for small parts and hevy part till 2000 Kg weight

The EDA300-MKII works with a method similar to the classic unified Rockwell Iaboratory hardness testers, so it is fully certifiable in accordance with DIN 50157 (EN-ISO 10109 and ASTM B724 standards on request).

The force on the diamond point is electronically controlled by an electronic load micro-cell directly inserted in the indenter (AFFRI® Patent).

The displacement detector includes the diamond and its support guide and it assures an absolute measurements with no interference due to movements, flexions and vibrations. It is not influenced by vibration source.

lt is possible to measure in an absolutely accurate way thin layers such as metal sheets, chrome plating only few hundredths of mm thick, very small pieces, nitrided layers and it is possible to measure with ease very large structures such as steel castings and moulds. It does not work using rebound, but with a real measurement of the indentation of the material. It is handy, light and very easy to use.

Standard delivery :

- Diamond indenter

- “V“ anvil for Ø from 1 to 10 mm

- “V“ anvil for Ø from 10 to 30 mm

- Flat anvil

Extra

- Printer

- Cable for computer

- The EDA300-MKII executes Automatic and immediate microvickers measurements without the need for optical measurements.

- Less effort, more accuracy, 2 seconds to perform a micro-hardness measurement

- An invaluable help both in the laboratory and in the manufacturing process for rapid,low cost,non destructive , direct and accurate measurements on parts during production.

- Conversion of the results to different Rockwell Brinell scales showed on the display.

- Functions such as: tensile strength, calculation of average, statistics, storage of data and output to printer are already included in the micro-tester software.

-Very high reliability and versatility of use, with a very wide range of supports pieces of any shape can be tested, from the point of a dentist’s drill to razor blades and many other pieces. Simply select the desired hardness scale and pressure to apply the test load. When the audio signal is heard, the test is completed and the results are instantaneously displayed. The EDA300-MKII is now ready for use again. It’s that easy.

- Interface for versatility. The microprocessor based controller can store more than 300 test results simultaneously, or be connected directly to a computer through the RS-232 interface, to a fixed or portable printer, making the EDA300- MKII a practical and versatile hardness tester.

Principle of operation : load with electronic control (49,05 N)

Fields of application : for all metals

Digital scale read out : Rockwell HRA (20...92); HRB (26...100); HRC (0...80);

HR15N (69...93); HR30T (16...83)

Brinell HB5 (5.. .205); HB30 (66...884)

Knoop (25...97)

Vickers (13...1865)

Tensile Module R sigma/Nmm2(226.. .2898N) HZA (0...250)

Webster B 0 – 20 (on request)

Barcol 0 – 100 (on request)

Display resolution : 0.1

Repeatability : ± 0.3% on reference test block

Storage of test results : 300 tests

Data transmission : RS 232 C (USB on request)

Statistics and mean of results : yes

Display : L C D graphic

Printer : Portable, 20 column thermal paper, rechargeable battery, measures (15 x 10 x 4 cm) - on request

Power supply : 1 rechargeable battery 110-240V

Operating time : 1000 tests

Automatic shut off after a pause of 2 minutes. Button reactivation

Total height capacity : from 0 to 170 mm

Minimum thickness measurable : 0.08 mm 600 Vickers

Ø measurable : from 0.5 mm to 150 mm

Total depth capacity : 75 mm

Dimension of electronic box :170 x 90 x 50h mm