Densitometers

Graphic & Printing Industry > Ink properties > Colorimetric and densitometric Control

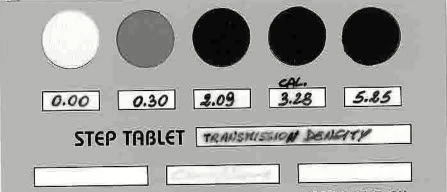

DTP 642 Transmission Densitometer

High precision mini densitometer with built in light source.

The BIGGEST among the small densitometers.

The only high precision densitometer for imagesetter set up and inspection of film processor.

Reliable density readings 0.00 to 6.00 D and extreme precision and repeatability in the reading of dot percentages, even the low ones.

These are the performances that the DTP 642 guarantees thanks to its stabilized light source and to the design reproducing in small the constructive solutions of professional bench densitometers.

Thanks to the DTP 642 your measurements will be accurate and the densitometric data detected reliable.

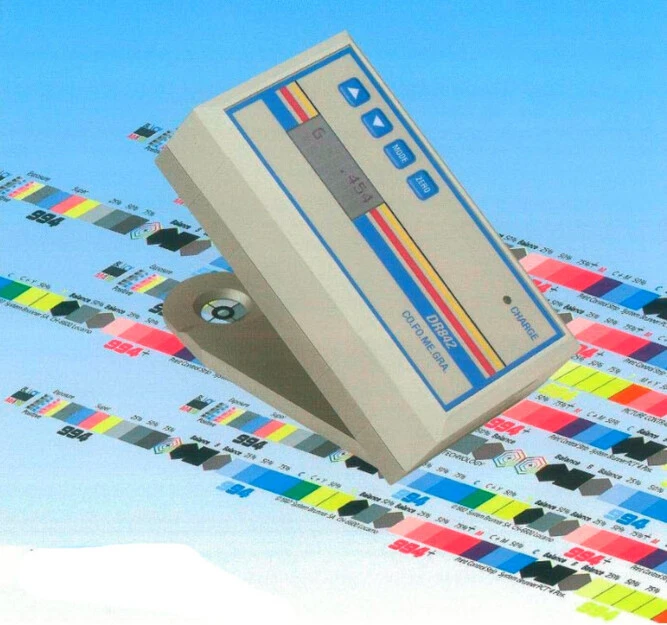

DR 842 DENSITOMETER FOR COLOR REFLECTION

Mini densitometer using extremely innovative technologies.

This mini densitometer has been realized with extremely innovative technologies and solutions that allow performances up to now never found in such a compact and low cost instrument.

The ultra-low-power micro-controller allows over 20000 measurements per charge.

The converter with 14 bit ensures extremely high precision and repeatability so as to allow the density readings up to 3 decimal points and the dot percentage readings to 1 decimal point.

The optical system developed in accordance with the ISO CD 14981 standard uses a light source of 9 LED (3 for each color), completely eliminating problems of rapid aging of the filters and of incandescent lamps, typical of densitometers of the past generation.

Measuring area of 3.5 mm diameter, on request of 2 mm diameter. Complete with carrying case, AC adapter charger, calibration tablet, RS232 serial interface, operation manual.

Tailored Models for Maximum Productivity

The SpectroEye portfolio has a solution for every need and price point

SpectroEye LT: an affordable entry-level solution that delivers the primary functions required for process control at the press. SpectroEye LT supports all the densitometric functions from density to trapping, as well as the CIE L*a*b* function.

SpectroEye LT: an affordable entry-level solution that delivers the primary functions required for process control at the press. SpectroEye LT supports all the densitometric functions from density to trapping, as well as the CIE L*a*b* function.

It is the ideal device to check CMYK prints according to ISO standards. SpectroEye LT can easily be upgraded to SpectroEye through the purchase of a software access code.

Also available in small aperture (SA) (see below for SA description)

SpectroEye: SpectroEye is ideal for customers who print CMYK and spot colors and who track systematic process control.

SpectroEye: SpectroEye is ideal for customers who print CMYK and spot colors and who track systematic process control.

Also for use in QA and ink mixing. Measures standard control bars utilizing 4.5mm aperture.

SpectroEye SA: For customers who have smaller control elements, SpectroEye SA is equipped with an aperture of 3.2mm designed specifically for reading patches as small as 3.5mm. With the identical accuracy of SpectroEye, SpectroEye SA offers customers who work with smaller control elements the option for unparalleled quality control, representing an incredible increase in production power. SA also available for SpectroEye LT

SpectroEye

Measurement functions Colorimetry : CIE L*a*b*, CIE L*C*h (a*b*), delta E* CIELAB

Special color deviation formulas : deltaE*2000,deltaE*94, deltaE CMC, delta E FMCII

Densitometry : Density, All densities (Grey Balance), Dot gain, Dot area, Trapping, Contrast, Print characteristic, Auto Function

Spectrum : Reflection spectrum

Range : from 380nm to 730nm - every 10 nm

Special functions : Best Match

Color guides : PANTONE PLUS SERIES FORMULA GUIDE Solid Coated & Solid Uncoated, DIC Color Guide; HKS E, K, N and Z

Software:

KeyWizard : included

Color Quality Basic version incl., Full version optional

Densitometry : Density, All densities (Grey Balance), Dot gain, Dot area, Trapping, Contrast, Print characteristic, Auto Function

Spectrum : Reflection spectrum

Range : from 380nm to 730nm - every 10 nm

Special functions : Best Match

Color guides : PANTONE PLUS SERIES FORMULA GUIDE Solid Coated & Solid Uncoated, DIC Color Guide; HKS E, K, N and Z

Software:

KeyWizard : included

Color Quality Basic version incl., Full version optional

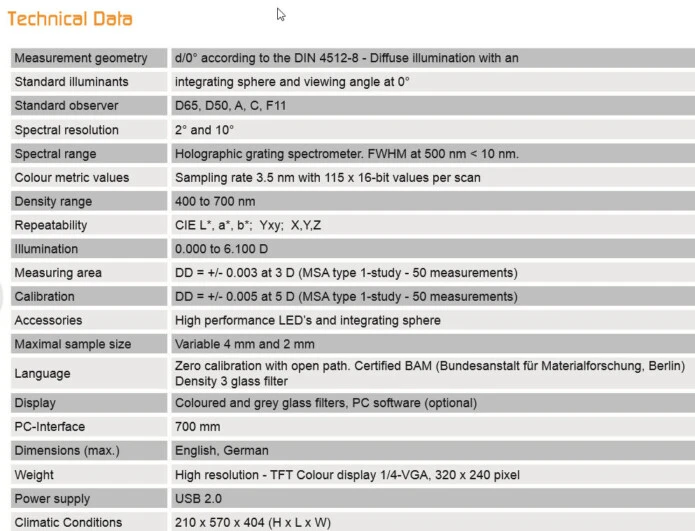

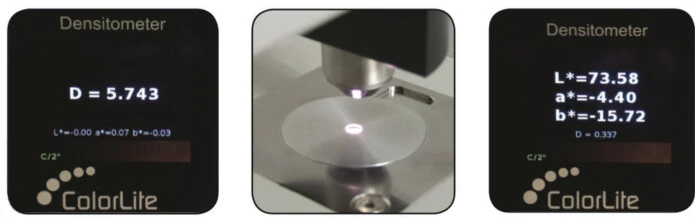

The new spectral densitometer sd350

The ColorLite sd350 is a spectral densitometer designed for the high demands of the automotive industry.

It measures transmission density values of optical film in the printing and screen printing industry.

- LED light source - over 20 year life span

- True grating spectrometer - over 100 sampling points in the VIS range

- Solid aluminium integrating sphere as an ideal diffuse illumination source

- 2 Channel system measuring density values from 0.000 to 6.000 +/- 0.003

- Designed and “Made in Germany”

The high quality device is characterised by a number of features which are not available in other densitometers on the market.

From the integrating sphere light source to the high resolution spectrometer, the sd350 sets a new standard for measuring the quality of optical films.

Using high performance LED’s, with a life span of over 20 years, and a grating spectrometer we can ensure perfect stability over its life time.

Apart from a long life, this results in high accuracy which makes it possible to directly communicate absolute values.

A high dynamic range is guaranteed by a 2-channel system.

Depending on the density of the film to be measured two separate measuring systems are used.

This means density values between 0D and 6D can be measured with 3 digits after the decimal point with a precision of 0.003 density values.

The spectral transmission function is evaluated with any number of response curves that can be programmed into the software.

Hereby evaluating with the CIE (Commission internationale de l’éclairage) colour matching functions, colour metric data such as L*, a*, b* can also be measured.

Unique selling points

• High accuracy through integrating sphere illumination and real grating spectrometer

• Changeable aperture for flexible application

• LED light source with a life span of over 20 years means high long term stability and low maintenance

• High resolution colour display

• Settings made with simple 2 button operation

• 115 measuring points per scan

• 2 channel system means high repeatability of +/- 0.003 D even at highest density values

• 350 mm maximum width of sample

• Calibration with BAM (Bundesanstalt für Materialforschung, Berlin) certified 3D glass filter • Simple zero calibration function

• Software variable response functions