Krebs Viscosimeter

Coatings & Industry > Physical properties > Viscosity & Consistency

B-One Plus

Touch the viscosity of your products with your fingers

The B-One Plus has a 7” touch screen and comes with a stylus.

This easy-to-use screen lets you see all measurement parameters at the same time.

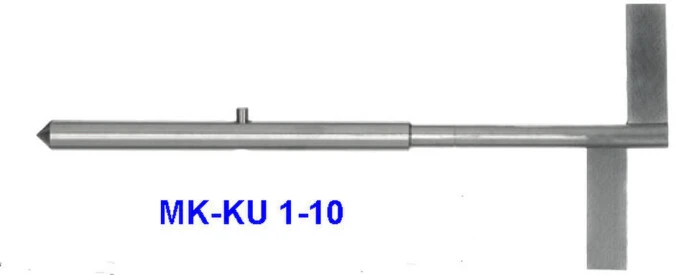

The B-One Plus can be used with the KREBBS MK-KU 1-10 Geometrie.

MS KREBS:

Krebs type measuring spindles compatible with ASTM D562 standard (316L stainless steel).

These systems are ideal for viscosity measurement in Krebs units in control of all types of products.

They can be used for direct measurement in user containers in 600 or 150ml beakers

B-ONE PLUS DIGITAL KREBS VISCOMETER

ASTM D 562, 856, 1131

This is a modern version of the traditional Krebs-Stormer viscometer used in the coatings industry.

This motorised instrument operates at a speed of 200 rpm without weights or pulley, and directly displays viscosity from 40 to 140 KU (Krebs Units).

The Krebs Stormer apparatus mesures a dynamic viscosity of a liquid.

The Stormer viscometer is used to measure viscosity of paints and other materials.

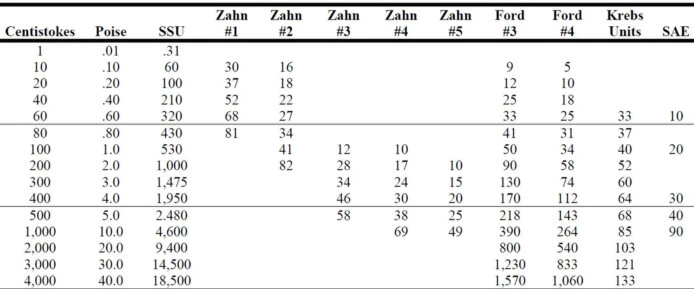

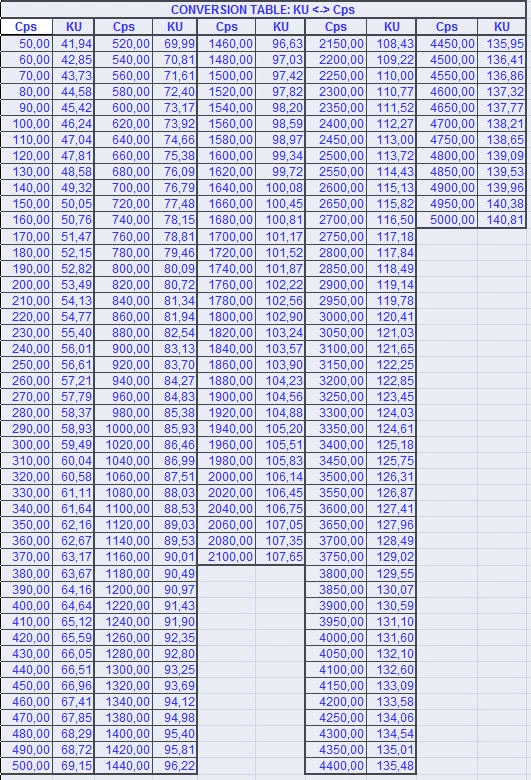

The viscometer uses the Krebs Unit (KU).

Spindle KU 1-10: viscosity range 20 - 5000 mPa·s (40 – 140 KU)

The KREBBS MK-KU1-10 rotational speed comply with ASTM method D 562.

Speed : 200 rpm

Repeatability: +/- 0,2 %

Container of paint : 500 mL (standardized) ; with the KU 1- 10 you can measure with 250 Ml

Display : Krebs Unit (KU), grams and mPa.s (cP)

Measurement time : Astm D 562 require to wait 5 s for the display reading to stabilize.

Two results, each the mean of two measurements on the same material by the same operator at different times are necessary.

Annual Calibration is recommended.

NO TEMPERATURE PROBE.

Option: control oil fluids: 64-79-84-95 or 106 KU (25°C).

VISCOMETER FIRST PRODIG

The viscometer with a 7 ‘’ touch screen allows you to create and save your measurement methods, display results or curves, analyse your data, print reports, manage users and protect data.

+Speed or shear rate control.

+Programming and recording method.

+Constant, step by step or ramp methods.

+Direct curve on display.

+Direct analysis with regression.

+Direct report editing.

+Direct measure with time to stop.

+Data recording and USB transfer.

+Integrated temperature probe.

+Printer connection.

+Display of viscosity limits according to mobile and speed.

+Programming and recording method.

+Constant, step by step or ramp methods.

+Direct curve on display.

+Direct analysis with regression.

+Direct report editing.

+Direct measure with time to stop.

+Data recording and USB transfer.

+Integrated temperature probe.

+Printer connection.

+Display of viscosity limits according to mobile and speed.