Bend & Impact Tester

Coatings & Industry > Mechanical properties > Flexibility and toughness

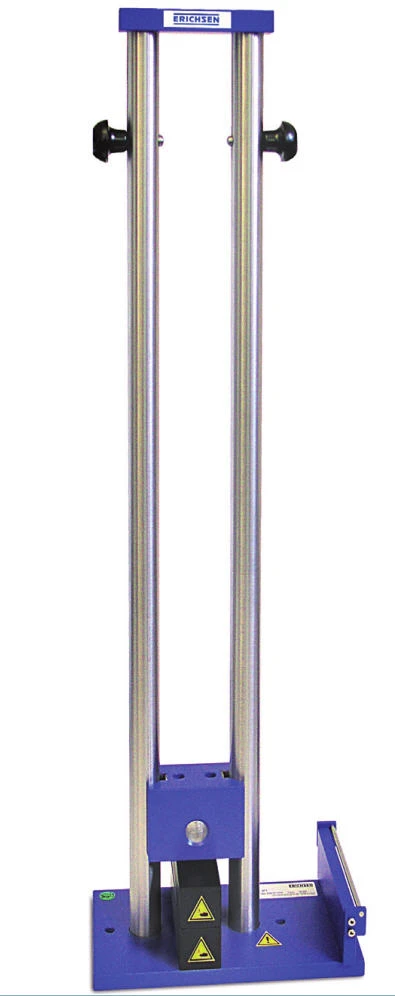

Bend and Impact Tester Model 471

Practical test method to determine the quality of coated metal sheets by deformation in a sudden blow.

Bend and Impact Tester, Model 471

Purpose and application

The Bend and Impact Tester is used to measure both flexibility and impact resistance of lightgauge sheet metal, or tube stock, coatings in a single operation.

The test simulates punching, beading, crimping and similar operations.

Test principle

A bent coated sheet metal panel is subjected to a prescribed impact force thus causing the cylindrical fold in the panel to be squeezed into a conical shape.

The test permits to determine the bending radius at which failure of the coating first occurs.

Evaluation

100 g Copper sulphate (Cu SO 4 x 5 H 2 O)

50 g Citric acid

0.5 ml Sulphuric acid (concentrated, spec. gravity 1.84)

are dissolved in 1 litre distilled water.

The test panel is submerged in this solution for 5 minutes and then rinsed under running water.

Any failures in the coating become visible in the form of lines or dots of corrosion.

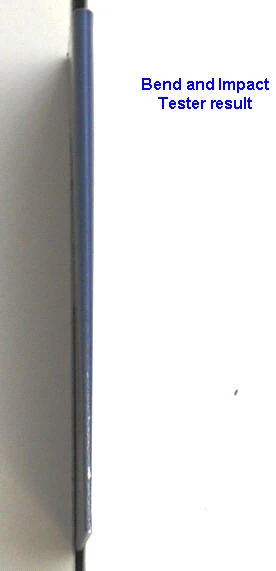

Test result

The length of the corrosion line is measured in mm together with the points starting from the buckling point (maximum fold). If this line is shorter, the better the formative qualities of the coating.