ISO 6270 & ASTM D 2247

Coatings & Industry > CORROSION > Humidity chamber

Humidity Cabinet

For humidity tests in accordance with international standards

For humidity tests in accordance with international standards

HYGROTHERM 519-529

- DIN EN ISO 6270-2 CH

- DIN EN ISO 6988

- DIN 50 958

- DIN 53 771

- DIN 55 991

- NFT 30-055

- ISO 3231

- ISO 4541

- ISO 11 503

- ASTM D 2247

This practice covers the basic principles and operating procedures for testing water resistance of coatings by exposing coated specimens in an atmosphere maintained at 100 % relative humidity so that condensation forms on the test specimens.

This practice uses the technique of creating a slight temperature differential within the exposure area to form condensation on the coated specimens. As the warmer saturated air passes the cooler specimens, water is deposited onto the specimens in the form of condensation.

This practice places the entire specimen in the exposure area allowing condensation to form on all surfaces. This makes this practice suitable for flat panels as well as large or 3D objects. This practice differs from other methods where condensation is only formed on the front coating surface, but the back surface is outside the exposure area.

This practice uses the technique of creating a slight temperature differential within the exposure area to form condensation on the coated specimens. As the warmer saturated air passes the cooler specimens, water is deposited onto the specimens in the form of condensation.

This practice places the entire specimen in the exposure area allowing condensation to form on all surfaces. This makes this practice suitable for flat panels as well as large or 3D objects. This practice differs from other methods where condensation is only formed on the front coating surface, but the back surface is outside the exposure area.

According with DIN EN ISO 6270-2, the condensation-water test atmospheres are designated as follows:

- Test atmosphere CH Condensation atmosphere with constant humidity

- AHT Condensation atmosphere with alternating humidity and air temperature

- AT Condensation atmosphere with alternating air temperature

HYGROTHERM 519 - 300 L

Purpose and Application

Corrosion protection systems and materials are tested in the humidity cabinet HYGROTHERM 519 in accordance with international standards and specifications. Examples are the reaction of protection-treaded carrier media in the condensed water climate (constant humidity climates CH in accordance with DIN EN ISO 6270-2).

The humidity cabinet HYGROTHERM 519 corresponds to the latest standards of technology. Setting-up and monitoring functions are kept to a minimum, or are undertaken automatically.

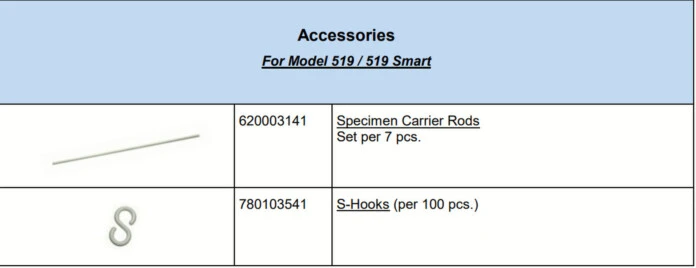

The 300 l standardised test chamber made of acidproof and thermoresistant plastic material ensures that the HYGROTHERM 519 is ideally suited to large-scale batch testing. The large, transparent access door allows easy mounting of specimens, which are hung from seven free-standing cross rails, to be exposed over a certain period aggressive climates or media.

The temperature is set on an electronic temperature regulator and the set value and actual value are shown on LED displays. According to the standards the test temperatures are between 20°C and 40°C (max. temperature 50°C).

HYGROTHERM 529

Purpose and Application

Corrosion protection systems and materials are tested in the humidity cabinet HYGROTHERM 529 (as described under Model 519) in accordance with international standards and specifications. Examples are the reaction of protection-treaded carrier media in the condensed water climate (constant humidity climates CH in accordance with DIN EN ISO 6270-2).

As an alternative to the model 519 with 300 l test volume the HYGROTHERM 529 is available for the testing of large-volume functional parts in the condensation-water climate (without addition of gas) with a test chamber volume of 1000 liters or 2000 liters.

The instrument consits of a control unit (incl. test duration counter and temperature regulator) for wall mounting as well as a separate double-walled test chamber in rectangular design with pneumatically dome opening