ARM

Process > Hardness

Back to the "Process" Menu

Conforms to ASTM E-3246 / ASTM E-18 / ASTM E-103 / ISO 6508 / ISO 6506

TEST LOADS up to 187,5 kgf (1839 N)

- ROCKWELL

- SUPERFICIAL ROCKWELL

- BRINELL HBWT

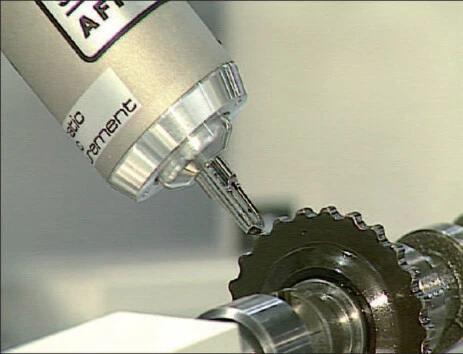

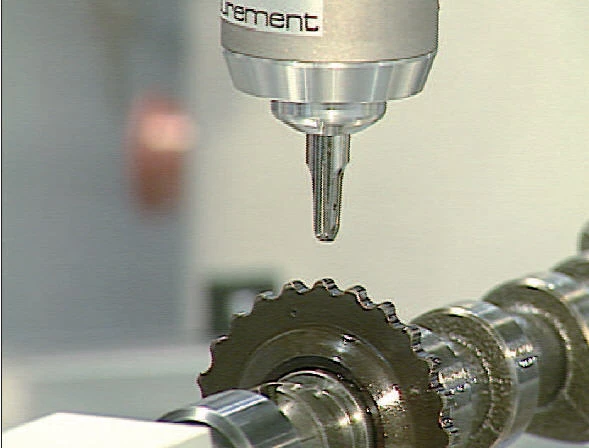

The most advanced technology to measure the hardness on board the CNC machine after milling and preparing the surface to be examined. On components of complex or bulky shape that would be impossible to perform in the laboratory. Know the hardness in a precise point thanks to the coordinates of the CNC machine; prepare the surface before performing a hardness test for perfect and real-time measurements without having to go to the laboratory. These are just some of the benefits with EXPLORER AFFRI thanks to its small size and low weight of only 2 Kg. Connection with all machining centers from which only the commands for positioning the probe are used. The accuracy of the measurements is guaranteed in any bad condition. The data is received by the BT radio receiver unit Data and values can be easily exported to a specific PC via the AFFRI software. A probe with extension is also available to access the most difficult points to measure.

Conforms to ASTM E-3246 / ASTM E-18 / ASTM E-103 / ISO 6508 / ISO 6506

TEST LOADS from 1 to 5,6 kgf (9,807 to 54,92 N)

- ROCKWELL

- SUPERFICIAL ROCKWELL

- BRINELL HBWT

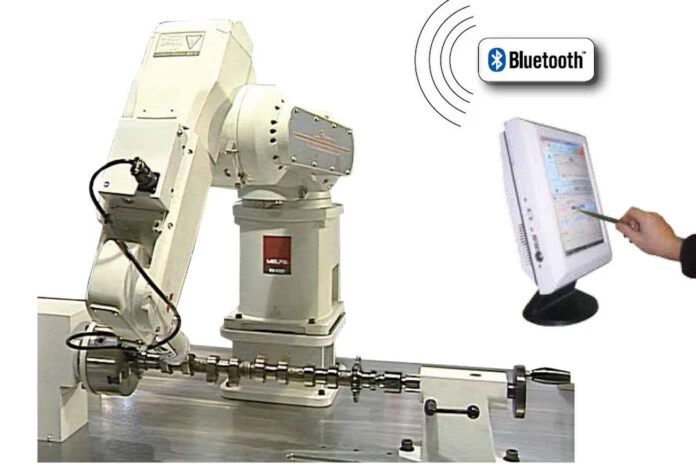

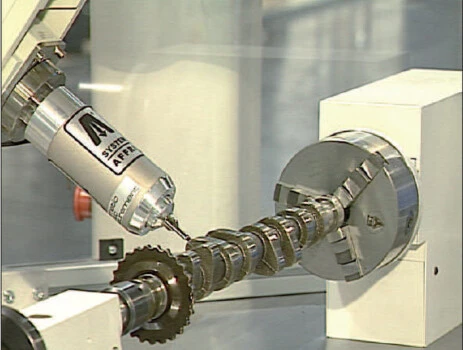

The measuring head of this durometer is anchored to a robotic arm which offers extreme mobility for accurate positioning on any area of the test piece to reach any point to be measured. allows single or multiple tests on any product.

Software dedicated to robot management offers a quick setting of all test parameters and a complete set for analyzing the data received from the instrument. It also has graphical analysis capabilities, test scale shortcuts, quick conversions, real-time statistics and test session storage.

Software dedicated to robot management offers a quick setting of all test parameters and a complete set for analyzing the data received from the instrument. It also has graphical analysis capabilities, test scale shortcuts, quick conversions, real-time statistics and test session storage.