Hardness Test Pencil

Coatings & Industry > Physical properties > Hardness

Hardness Test Pencil, Model 318

For the Measuremen of the Hardness of Protective Coatings

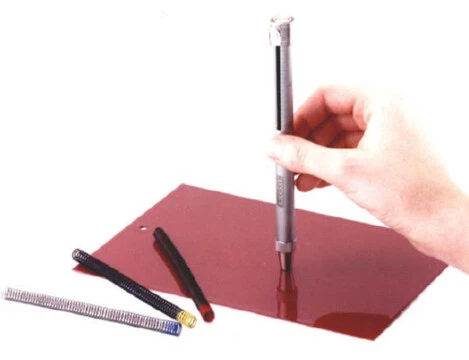

The degree of hardness of paint films, plastic coatings, etc. can be accurately measured and recorded with the Hardness Test Pencil, Models 318 and 318 S, no matter whether on a level or curved surface, small or large.

The instrument is always ready for use and, because of it’s small size easy transportable, an asset which will be appreciated by all concerned with hardness tests.

The handling of the Hardness Test Pencil is extremely simple.

The estimated or known spring tension is set with the help of the slider. Holding the instrument upright and placing its point on the test surface one draws a 5 to 10 mm long line at a rate of approximately 10 mm/sec.

The stylus should produce a scratch which is just visible with the naked eye. If the spring pressure is too high, the scratch is clearly visible; if too low, no scratch appears. The applied pressure, fixed by locking the slider, is marked in Newtons

The handling of the Hardness Test Pencil is extremely simple.

The estimated or known spring tension is set with the help of the slider. Holding the instrument upright and placing its point on the test surface one draws a 5 to 10 mm long line at a rate of approximately 10 mm/sec.

The stylus should produce a scratch which is just visible with the naked eye. If the spring pressure is too high, the scratch is clearly visible; if too low, no scratch appears. The applied pressure, fixed by locking the slider, is marked in Newtons

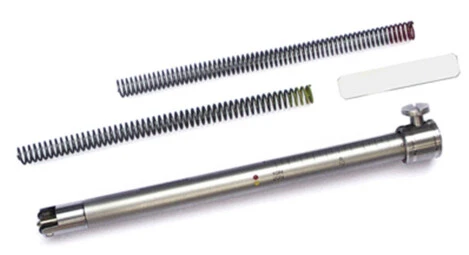

3 Pressure Ranges:

- 0 - 3 N (blue marked)

- 0 - 10 N (red marked)

- 0 - 20 N (yellow marked)

4 Test Geometries:

- 0.75 mm (Bosch)

- 1.0 mm (ISO)

- 0.5 mm (van Laar)

- 0.5 mm (Opel)

1 Diamond test tip :

- Ref : 101-02180132 455.00

- 413-318 Diamond test tip acc. to DIN EN 438-2 and ISO 4586-2 (with 90 degree included angle and 90 µm radius on the point).

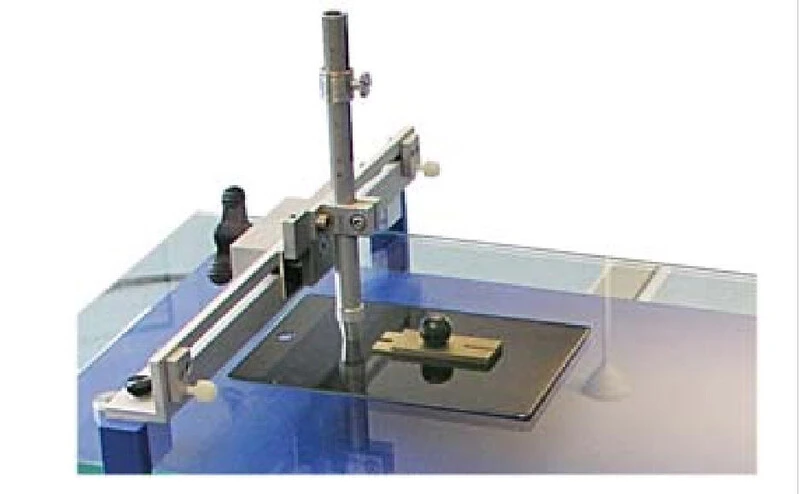

Hardness Test Pencil, Model 318 S with rolling head

For the Measurement of the Hardness of Protective Coatings

Technical Data:

Compression Springs: spring steel

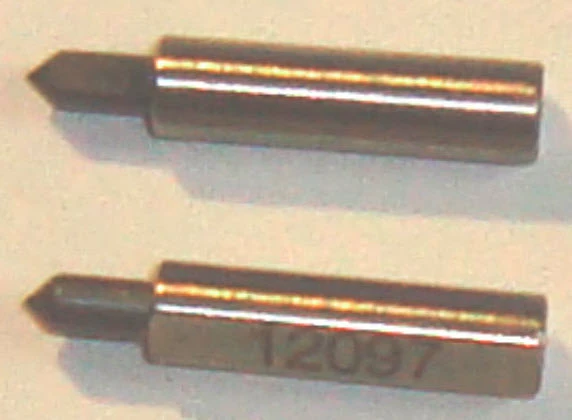

Marking pins

- nos. 1, 2 and 3: tungsten carbide spheres

- no. 4 spring steel, with special tip geometry

Stylus point diameter:

- no. 1 0.75 mm (Bosch)

- no. 2 1.0 mm (technically equivalent to ISO 1518)

- no. 3 0.5 mm (van Laar)

- no. 4 0.5 mm (Opel)

1 Diamond test tip :

- Ref : 101-02180132 455.00

- 413-318 Diamond test tip acc. to DIN EN 438-2 and ISO 4586-2 (with 90 degree included angle and 90 µm radius on the point).

Total length: 160 mm

Diameter: 16 mm

Weight, net: approx. 250 g

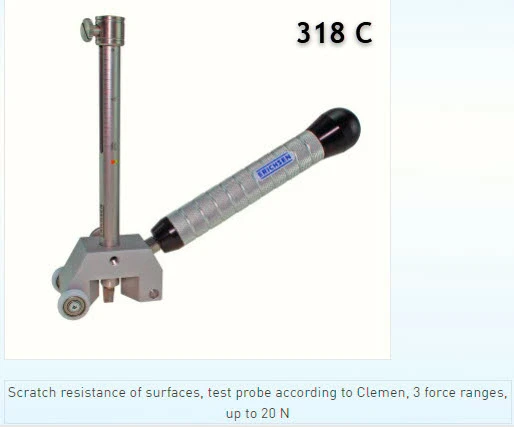

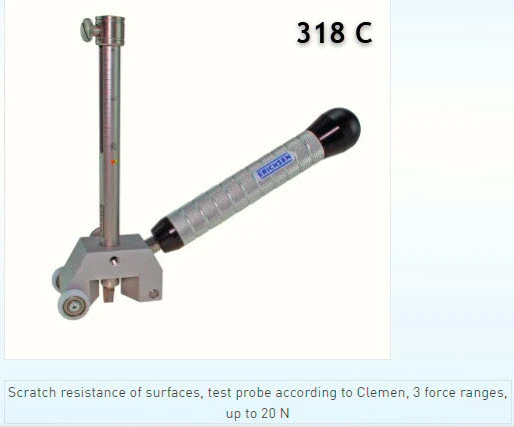

318 C

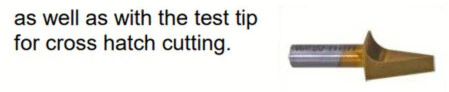

The hardness test rod, model 318 C can be equipped with two types of sharp-edged tool: With the test tip in accordance to Clemen as well as with the test tip for cross hatch cutting.

The vertical positioning is achieved by the use of the rolling chucking adapter with handle (lockable).

The pointer finger of the guiding hand presses directly onto the rolling chucking adapter and ensures by that the preset test force, whereas the rest of the hand just guides the testing performance by pulling the handle.

The three nylon wheels provide the corresponding stability for the vertical placement and guidance. Fig. Model 318 C with chucking adapter and handle

An existing hardness test pencil 318 can easily retrofitted by separately ordered test head, test tips, chucking adapter and handle.

Scratch Hardness Testing

Gash/metal marking according to Oesterle, 3 test disks: Steel, copper, thermo-set plastic,

3 load available : 0–3 N/0–10 N/0–20 N

Mar Tester Model 435

Adhesion and Resistance Tester Model 435 S

Model 435

Gashes and mars are not nice to look at, especially not on smooth, shiny paint surfaces.

But they can occur quite quickly: fingernails can unintentionally scratch over a matt-polished table.

Or, a branch can grind across the beautiful paint of a Cadillac.

The mar is often from a small cause but can leave a big mess!

Metal marking is another type of mar. Here, the culprits are small metal particles of coins or similar which "rub off", thereby leaving ugly scratches on the surface.

Previously you could "inspect" a surface only with your fingernails.

Now for the first time, the Model 435 Mar tester enables you to specifically define the behaviour of coating surfaces with an exact test value.

Scars on surfaces are unsightly, especially on smooth, glossy surfaces. Surfaces can be ruined so easily - for example marks on the matt polished

surface of a table, by a fingernail, or on the shiny bodywork of a Cadillac, by a twig. Great annoyance can result from such small causes.

Marks can also be caused by metallic objects. The culprits may be metal particles from coins, cutlery or rings on fingers. Any of these can mar surface finishes.

The traditional test for the resistance of surfaces to such damage was to try to mark the surface with a fingernail.

With the Mar Tester, Model 435, the quality of the surface can be measured accurately.

Model 435 S

In principle, the Model 435 S is suitable for testing the adhesion of almost all printed scales, numbers, inscriptions and markings.

When used as an adhesion tester e.g. the coloured coating applied to the dial of a speedometer in the shape of raised numbers, points or scale lines, is tested concerning its adhesion to the substrate, by lateral slipping with a defined “blunt” test body geometry, with a preselected test force.

When used as a scratch resistance tester for testing surfaces against “blunt” effects, it is recommended for testing surfaces on which the Hardness Test Rod 318 is still too “aggressive” – even using the largest tip diameter of 1 mm available for this purpose.

Hadness Test Pencil

Order number: 101-0020.01.31

incl. test tip no. 1 (acc. to Bosch; 0,75 mm Ø) and 3 springs

incl. test tip no. 1 (acc. to Bosch; 0,75 mm Ø) and 3 springs

Hadness Test Pencil

Order number: 101-0273.01.31

with rolling head, incl. test tip no. 1 (acc. to Bosch; 0.75 mm Ø) and 3 springs

with rolling head, incl. test tip no. 1 (acc. to Bosch; 0.75 mm Ø) and 3 springs

Hadness Test Pencil

Order number: 101-0314.01.31

Hardness Test Pencil, Model 318 C (Clemen) incl. test tip acc. to Clemen (R Ø 1 mm), chucking adapter (rolling – for fixing and vertical guidance of the Hardness Test Pencil), handle (anti-slip grip) and 3 springs

1,294.--

Hardness Test Pencil, Model 318 C (Clemen) incl. test tip acc. to Clemen (R Ø 1 mm), chucking adapter (rolling – for fixing and vertical guidance of the Hardness Test Pencil), handle (anti-slip grip) and 3 springs

1,294.--

Hadness Test Pencil

Order number: 101-0428.02.32

Test tip no. 1 (acc. to Bosch (Ø 0,75 mm) for scratch test acc. to BMW GS 97034-9)

Test tip no. 1 (acc. to Bosch (Ø 0,75 mm) for scratch test acc. to BMW GS 97034-9)

Hadness Test Pencil

Order number: 101-0428.03.32

Test tip no. 2 (acc. to ISO 1518 and GME 60280 (Ø 1.0 mm)

Test tip no. 2 (acc. to ISO 1518 and GME 60280 (Ø 1.0 mm)

Hadness Test Pencil

Order number: 101-0428.04.32

Test tip no. 3 (acc. to van Laar; 0.5 mm Ø)

Test tip no. 3 (acc. to van Laar; 0.5 mm Ø)

Hadness Test Pencil

Order number: 101-0428.01.32

Test tip no. 4 (acc. to Opel; 0.5 mm Ø)

Test tip no. 4 (acc. to Opel; 0.5 mm Ø)

Hadness Test Pencil

Order number: 101-0428.05.32

Hadness Test Pencil

Order number: 101-0218.02.32

Hadness Test Pencil

Order number: 101-05640132

Test tip for cross hatch cutting (30°) additionally covered with an extremly hard layer

(short shaft with flat clamping area)

Test tip for cross hatch cutting (30°) additionally covered with an extremly hard layer

(short shaft with flat clamping area)

Hadness Test Pencil

Order number: 101-02180132

Diamond test tip acc. to DIN EN 438-2 and ISO 4586-2

(with 90 degree included angle and 90 µm radius on the point).

Diamond test tip acc. to DIN EN 438-2 and ISO 4586-2

(with 90 degree included angle and 90 µm radius on the point).

Hadness Test Pencil

Order number: 101-0429.01.32

Spring 0 - 3 N blue marked

Spring 0 - 3 N blue marked

Hadness Test Pencil

Order number: 101-0429.02.32

Spring 0 - 10 N red marked

Spring 0 - 10 N red marked

Hadness Test Pencil

Order number: 101-0429.03.32

Spring 0 - 20 N yellow marked

Spring 0 - 20 N yellow marked

Hadness Test Pencil

Order number: 101-30070132

Test head „318“ for using test tips no. 1 up to no. 4 and test tip for writing

inclination test acc. to BMW

Test head „318“ for using test tips no. 1 up to no. 4 and test tip for writing

inclination test acc. to BMW

Hadness Test Pencil

Rolling test head „318 S“ usable with:

- test tips no. 1 up to no. 4 and

- test tip for writing inclination test acc. to BMW

- test tips no. 1 up to no. 4 and

- test tip for writing inclination test acc. to BMW

Hadness Test Pencil

Order number: 101-30120132

Rolling test head „435“ for using test discs made of Duroplast, Copper and Stainless Steel

Rolling test head „435“ for using test discs made of Duroplast, Copper and Stainless Steel

Hadness Test Pencil

Order number: 101-30120232

Rolling test head „435 S“ for using a test tool made of Steel

Rolling test head „435 S“ for using a test tool made of Steel

Test head „C“ (movable/retrofit) for models 318/318 S, for using the Clemen test tip

Hadness Test Pencil

Order number: 101-2109.01.32

Attention: Requires a Clemen test tip as well as a chucking adapter (rolling – for fixing and vertical guidance of the Hardness Test Pencil) and handle (anti-slip grip)

Attention: Requires a Clemen test tip as well as a chucking adapter (rolling – for fixing and vertical guidance of the Hardness Test Pencil) and handle (anti-slip grip)

Order number: 101-1972.01.32

Hadness Test Pencil

Order number: 101-1969.02.32

Handle for the chucking adapter adaptable anti-slip grip made of aluminium with engraved grid pattern, with freely rotating axis for constant force application. When using Model 318 C, the rotation function has to be locked.

-

Handle for the chucking adapter adaptable anti-slip grip made of aluminium with engraved grid pattern, with freely rotating axis for constant force application. When using Model 318 C, the rotation function has to be locked.

-

Order number: 101-0708.01.32

Order number: 101-0769.01.32

Hadness Test Pencil

Order number: 101-04300132

Test disc made of Duroplast

Test disc made of Duroplast

Hadness Test Pencil

Order number: 101-04300231

Test disc made of Copper

Test disc made of Copper

Hadness Test Pencil

Order number: 101-04300332

Test disc made of Stainless Steel

Test disc made of Stainless Steel

Hadness Test Pencil

Order number: 101-07960132

Test tool made of Steel

Test tool made of Steel