Coil Coatings Oven

Laboratory Product > Heating

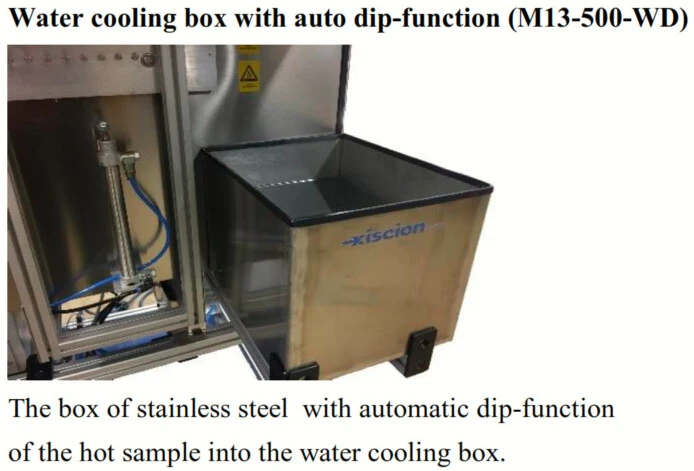

Coil Coating Laboratory Oven M13-500

Improved model !

- Only 12 kW heat effect instead of 18 kW and with better test results. Energy efficient in comparison.

- More accurate sample results

- Ergonomic and servicefriendly construction

Auto Load System

The oven gives total control of the full heatings process of the sample:

- Repetetive process to change samples

- Safe and fast handling for the operator

- Superior ergonomics

Warranty

- One-year warranty for fabrication disorder at application

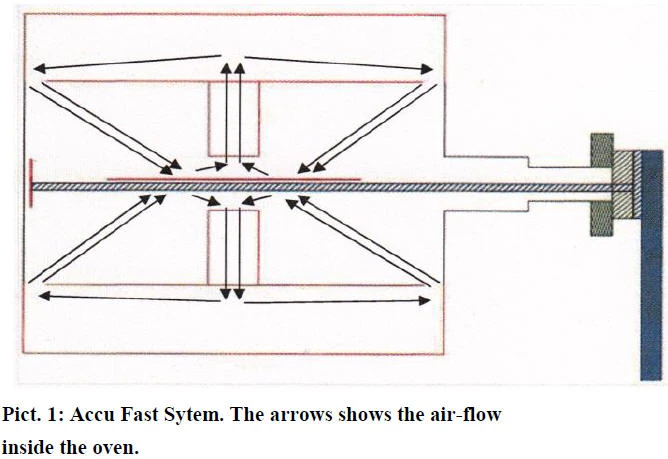

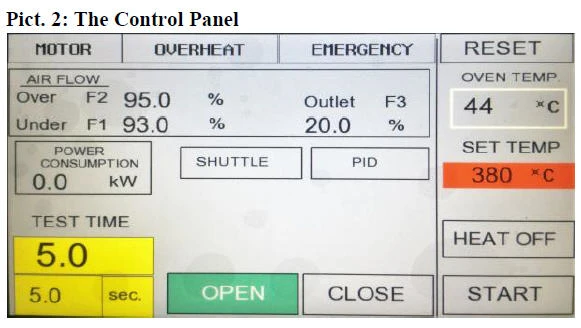

Separate frequency converters to control the air-flow for upper heat, lower heat and ventilation.

Thermocouples to measure upper heat, lower heat and for overheat protection.

The temperature regulator is controlled by the PLC.

Options : three models available

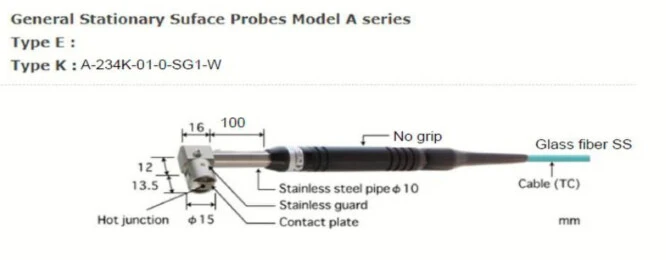

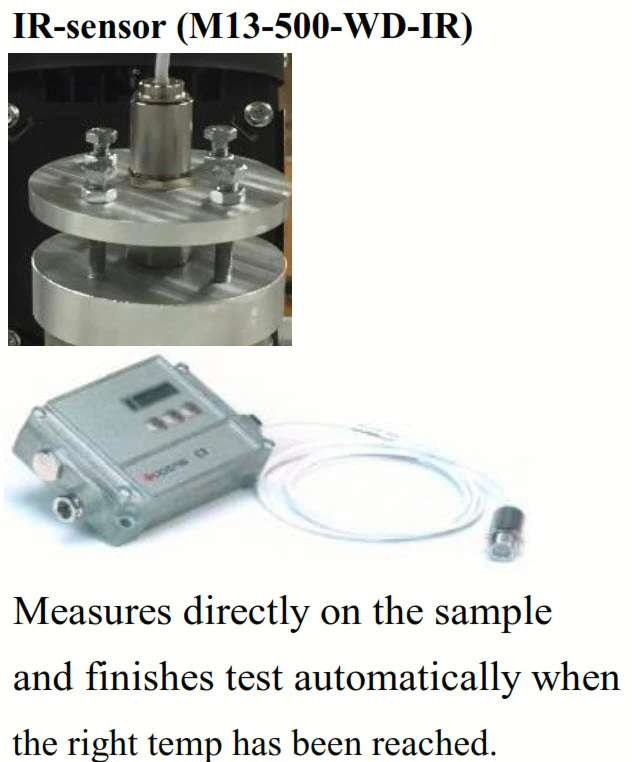

Temperature sensor technical data

Temp. range : -50°C to 500°C

Tolerance ; -50°C ... 333 °C : +/- 2,5 °C

333°C...500°C : +/- (0.0075 x measured t°)°C

Response time : 1,5 sec

Durability : more than 75.000 contacts

Cable type and length : Type K: SG-K 1 m

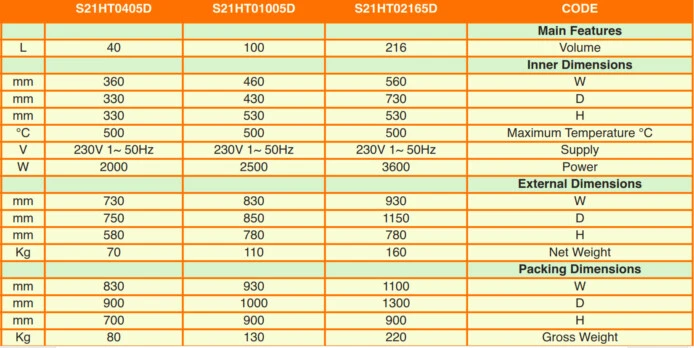

21HT High Temperature Ovens + 500°C

21HT Thermostatic Ovens by Galli suitable for your applications: precise thermostating, heating, drying, polimerization, expansion, cooking, stabilization, tempering, fixing, bonding, heat treatment, accelerated aging, sterilizing, burn-in, inert atmosphere treatments.

PLUS

• AG-System Control: PID Digital Microprocessor, careful and sensitive. Version DAILY, PRO, TALENT

• Range Temperature: from +50°C to 500°C, on request max + 700°C

• Double Digital Display visualize simultaneously the set point and the inner Temperature

• Safety Device, Class 3.1

• Accessories, custom versions, temperatures available on request

• Dynamic and homogeneous Forced Air Circulation System

• 3 sizes, bench top model: 40, 100, 216 Litres

• Made in Italy

• Range Temperature: from +50°C to 500°C, on request max + 700°C

• Double Digital Display visualize simultaneously the set point and the inner Temperature

• Safety Device, Class 3.1

• Accessories, custom versions, temperatures available on request

• Dynamic and homogeneous Forced Air Circulation System

• 3 sizes, bench top model: 40, 100, 216 Litres

• Made in Italy

The High-Performance Thermostatic Ovens model 2100 with Forced Air System are ideal for all those applications where an accurate, reliable, and high-performance device is needed, and are used in research and biological, chemical, and pharmaceutical laboratories.

2100 Thermostatic Ovens are essential in a wide range of tests and drying process, in stability tests, accelerated ageing tests and sterilization treatments.

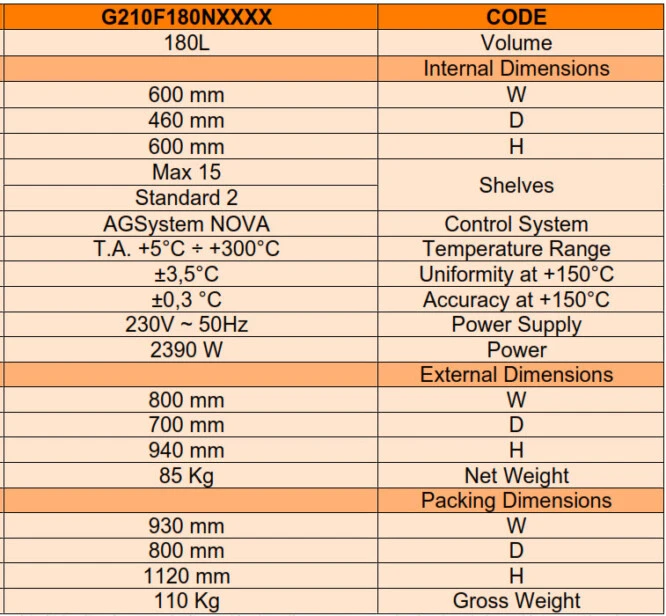

Control System AGS NOVA

- Touch Screen Color Display.

- AUTOMATIC Function with continuous temperature monitoring.

- PROGRAM Function with 20 Programs, 12 Steps with Ramps and Soaks.

RECORDING Function with Graphic Temperature Recording.

- Set Point and Inner Temperature Visualization.

- Optimized Control Algorithm with PID Actions.

- Autotuning Function.

- Platinum PT100 Probe, Class A.

- “Zero Crossing” Solid State Relays. USB Port.

Temperature Range from Ambient Temperature +5°C to +300°C

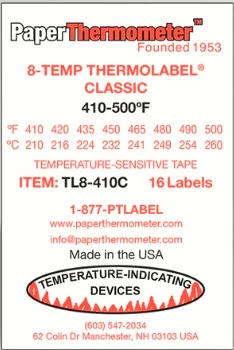

How do you know the curing temperature of your sample?

Paper thermometers make it easy!

Find out instantly the maximum temperature reached by your samples.