Cathodic Delaminator

Coatings & Industry > CORROSION > Corrosion Quick Test

Cathodic Delaminator, Model 602

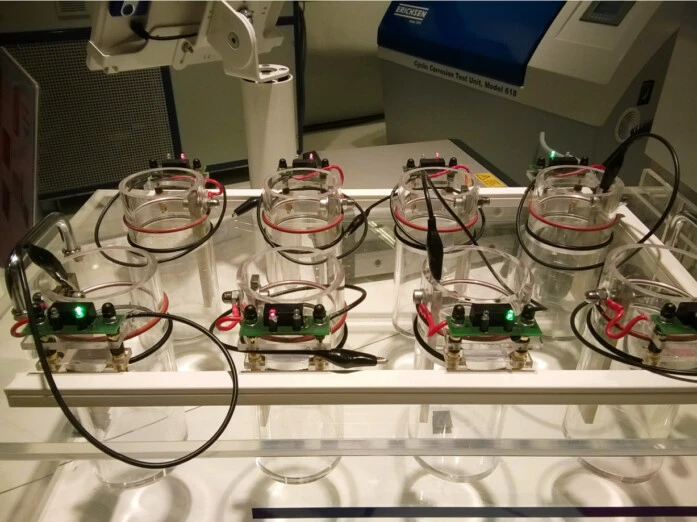

The Cathodic Delaminator, Model 602, is used for rapid checking of product quality and frequently quality control of coated metals.

The apparatus consists of a control unit and a temperature control vessel (immersion container) with 8 test receptacles and circulator.

Each test vessel has its own constant current source.

So you can use up to 8 specimen for testing, independently of each other.

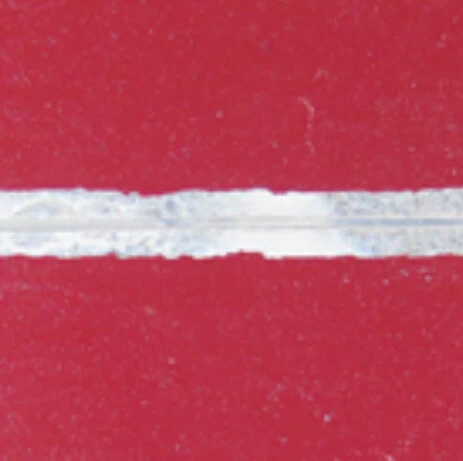

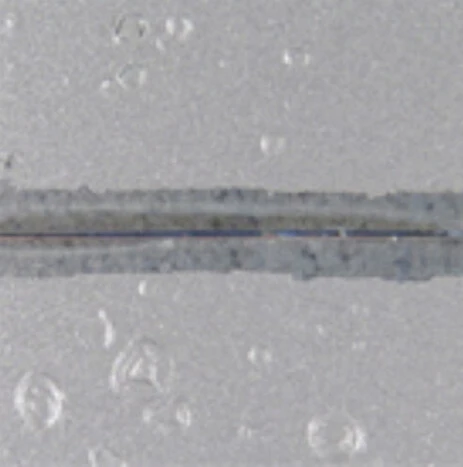

The cathodic delamination allows the determination of infiltration of the coating in the damaged area and erroneous pretreatments can be made visible (formation of bubbles during pinholes, scratches or stone impact).

Purpose and Application

Mechanical injury of organic coatings on metal cause the loss of corrosion protection.

Known examples of the mechanical destruction of coatings are : stone impact on motor vehicles, transport and installation damage.

Corrosion will be affected by corrosion protection system.

Particularly the preparation of the substrate surface before coating and the composition of the coating are important for corrosion protection systems.

The Cathodic Delaminator, Model 602, is used for rapid checking of product quality and frequently quality control of coated metals.

The apparatus consists of a control unit and a temperature control vessel (immersion container) with 8 test receptacles and circulator.

Each test vessel has its own constant current source.

So you can use up to 8 specimen for testing, independently of each other.