Metallic Coating Gauge

Coatings & Industry > Physical properties > Thickness Dry Film

K5-C

Metallic coating Thickness gauge

Dry film coating thickness

Thickness measurement of:

— dielectric (paint, lacquer, enamel, plastic, teflon, anodic oxide, mastic and other) coatings on products from ferrous and non-ferrous metals;— galvanic (nickel, zinc, chrome, cadmium, tin, silver, copper and other) coatings on products from ferrous and non-ferrous metals;— multilayer coatings (layer by layer);— plated coatings;— special conductive coatings on products from metals and plastics;— lacquer, paint and galvanic coatings on inner surfaces of pipes and cylindrical products;— protective layer of concrete and determination of steel reinforcement position in concrete;— wall thickness of large products from fiberglass and carbon fiber reinforced plastics during manufacture and delivery with one side and two sides access;

K6-C Multifunctional Coating Thickness Gauge

Purpose

K6-C Multifunctional coating thickness gaugeThickness measurement of:

— galvanic (zinc, chromium, nickel, cadmium, silver, tin and other) coatings on steel products;— galvanic (zinc, chromium, nickel, cadmium, silver, tin and other) coatings on products from non-ferrous metals;— paint, lacquer, enamel, powder, mastic and other dielectric coatings on steel products;— anodic oxide, phosphate and other dielectric coatings on ferrous and non-ferrous metals;— special dielectric and metallic thick coatings, plated coatings;— coatings on the internal surfaces of pipes and cylindrical products;— copper foils on printed circuit boards;— sheets of conductive non-ferrous materials and galvanic coatings on products from dielectric materials;— two layers coatings;— protective layer of concrete and determination of steel reinforcement position in concrete;— wall thickness of large products from fiberglass and carbon fiber reinforced plastics during manufacture and delivery with one side and two sides access;

Measurement of groove depth and evaluation of surface roughness after sand blasting or grit blasting;

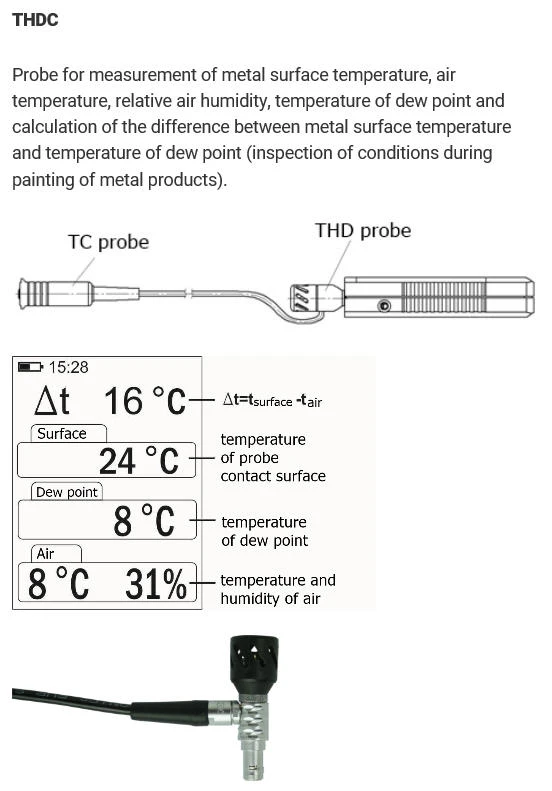

Control of climatic conditions (air humidity, air and metal surface temperature, dew point temperature and determination of TΔ parameter).

| COATING | BASE | PROBE |

Paint, powder, plastic, enamel and other non-ferrous dielectric coatings | Conductive ferrous and non-ferrous materials | FNF |

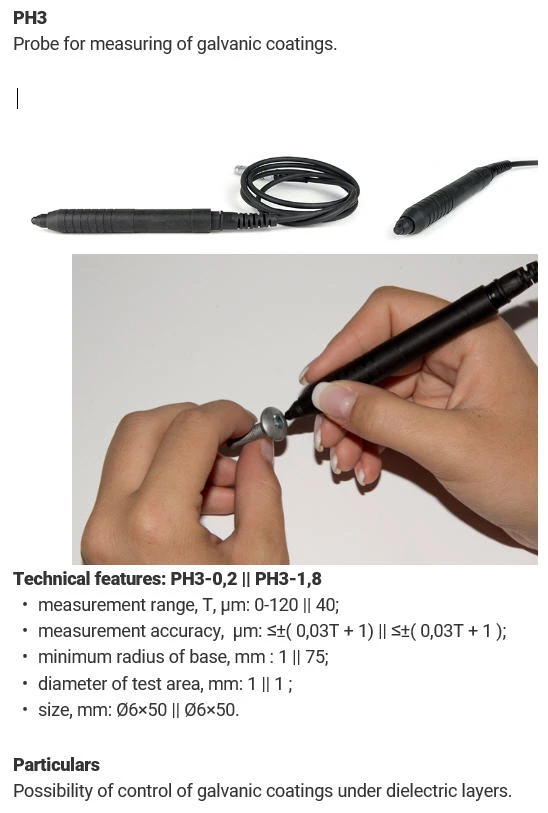

| Electrolytic Nickel | Steel, ferromagnetic stainless-steel | PH1 / Ph3-0,2 |

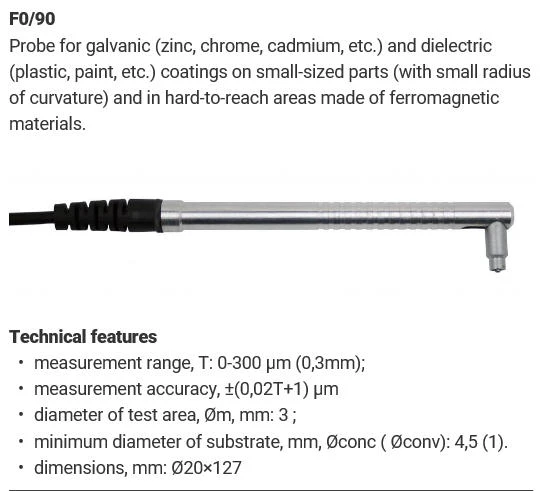

| Tin, Chromium, zinc, copper-zinc alloys, cadium, silver | Steel, ferrous, stainless-steel | PH3-1,8 / Ph3-0,2 F0, F1 |

| Chemical nickel, phosphating | Steel, ferrous stainless steel | F1 |

Zinc, cadmium | Copper, brass, bronze | NF0 |

| Chemical nickel | Aluminum and aluminum alloys, titanium and titanium alloys | NF0 |

| Tin, tin alloys (Sn-Bi Sn-S, etc.), chromium | Copper and copper alloys, titanium alloys, aluminum and aluminum alloys | NF0 |

| Aluminum (plating) | Aluminum alloys | Ph3 |

| Electrolytic nickel | Non-ferrous materials (copper, brass, bronze, aluminum and its alloys, titanium alloys, alloyed stainless steel, etc.), dielectrics | Fl Ni |

Copper | Dielectrics (fiberglass, synthetic resin bonded paper | Ph3 |

| Electrolytic nickel | Copper or brass Samples are necessary for settting of the probe. | FG |

| Tin, zinc, gold, silver | Brass Samples are necessary for settting of the probe. | NFG |

| Tin, zinc | Copper Samples are necessary for settting of the probe. | NFG |

| Three calibration characteristics can be saved in NFG probe memory. | ||

First we can look at the samples free of charge and say what will be possible for sure.

We have to investigate for the electrophysical properties of your materials

Then we can provide an inexpensive thickness verification of your samples (destructive measurements) of one set of samples to set of the probe. Destructive measurement is very time consuming task.

Technical details of the coated parts which are important:

coating thickness range: minimum and maximum thicknesses (eg. it would not be a good idea to try to measure 2 um of gold as such thickness more or less lies in the measurement error of the device), dimensions shape of the parts, surface roughness, other sublayers or layers above if present.

F1Ni — Thickness measurement of galvanic coatings (with the exception of nickel electrolytic), paint-and-lacquer and other non-ferromagnetic coatings on small-sized components made of ferromagnetic materials.