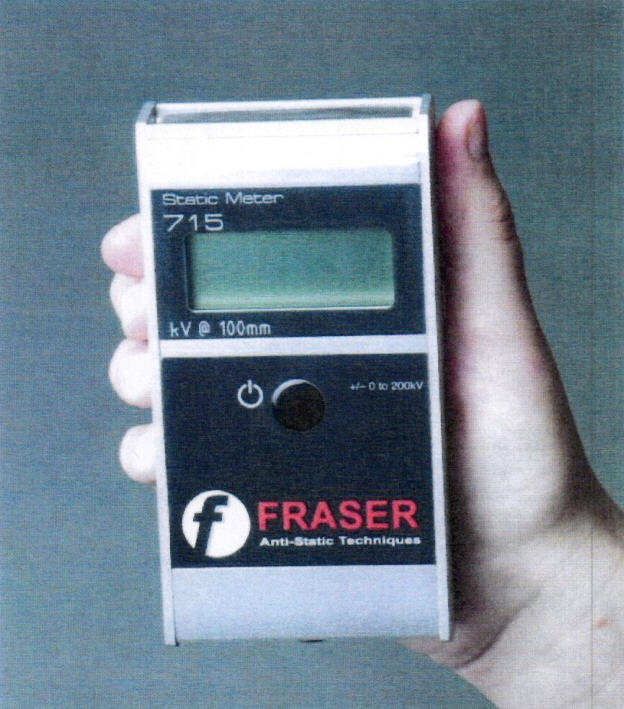

715 Static Meter

Coatings & Industry > Surface Tension

715 STATIC METER

The 715 Static Meter has been developed to enable industrial engineers to investigate static electricity problems.

Its accuracy, stability and ease of use make it the leading instrument in its class.

- The 715 measures static electricity on the surface of a material, at a distance of 100mm.

- The meter can show where and how the static is generated, its magnitude and its polarity.

- The 715 monitors the effectiveness of the action taken to solve the problem. If the solution involves static control equipment, the 715 shows its most effective position.

- The 715 allows the engineer to set standards to avoid future problems.

- These can range from an acceptable level of charge in materials, to charge levels in products being produced by the process.

- The 715 has two ranges selected automatically

- The high range measures up to 200kV with a resolution of 100V.

- The low range measures up to 20kV with a resolution of 10V.

There is a "hold" facility to freeze the reading on the display.

How the 715 works:

Static electricity is a potential problem in many industrial areas.

It slows production, reduces product quality, attracts contaminants and gives shocks to operators.

The 715 enables the engineer to investigate these static electricity problems scientifically.

Static is a coulombic charge - forming current when it moves, but difficult to measure when it is not moving.

The 715 measures the surface voltage using Q=CV : the 100mm reading distance is the constant capacitance which allows the voltage to vary directly with the charge.

EX 715 Atex Static Meter

- 2 switchable ranges of measures (0 to ±200kV/100V and 0 to ±20kV/10V)

Maintenance kit

It consists of a brush and a special cleaning liquid.

Static control products become dirty for three reasons:

1. The strong electric field naturally attracts airborne dust and contaminants.

2. Carbonisation of the air by the high voltage results in a deposition of carbon onto the body of the electrode.

3. In some applications, such as coating and printing, the contamination may be from the ink or coating. Some plastics applications produce gases which can cover the electrode with a conductive coating.

Contamination reduces performance by diverting energy away from the emitter pins - the dirtier the ioniser, the less efficient it is.

In some cases the contamination may overload the system, causing it to shut down.