Corrosion Tests Analysis

Coatings & Industry > CORROSION > Corrosion ANALYSIS

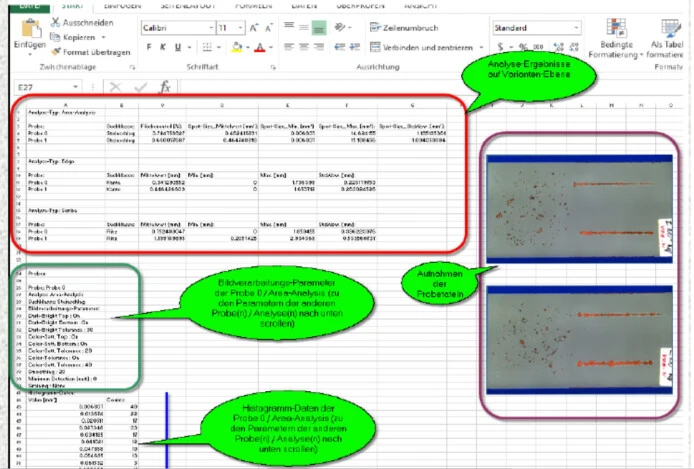

Analysis System QUANTIZ® QUANTIZ® Light

Combination of hard- and software, especially for image capture and image analysis at corrosion tests

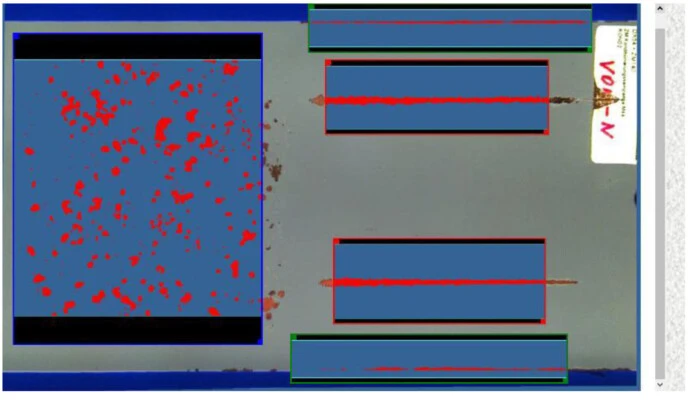

- Scribe delamination

- Edge corrosion

- Corrosion on the surface

Purpose and Application

QUANTIZ® provides an automatic evaluation and documentation of various corrosion samples.

The Analysis System QUANTIZ® and QUANTIZ® Light are a combination of hardware and software, especially for the automatic evaluation and documentation of various corrosion samples; connectable via USB cable to standard laptops / PCs (must be provided by the user).

The specially designed lighting technology enables the analysis on different contrast levels and allows specifically for filiform corrosion samples to evaluate them without manual removal of the affected paint coats.

Evaluation of results by camera system vs. manual result evaluation

- Any visual or manual evaluation, y ranking or classifying of the results is sufferingof the following:

- Visual evaluation & judgment trough the users'eyes include the "human error"

- Individual impression by the user is time-limited in his mind & remembrance.

- No digital documentation.

- An automatic evaluation by a digital vision system can provide the following advantages:

- Exclusion of the "human error".

- "Impression" is exchanged against measurement and the validity & access to the values is not time-limited.

- Objective, precise and repeatable results.

- Digital communication

- EN ISO 21227-2 is making a good approach to describe a standard vision system to achieve reliable results.

- Design parameters of EN ISO 21227-2 as the following:

- Pixel resolution: min 6 pixel / mm

- Illumination: Diffuse bright field (recommended)

- Area of Interest (AOI): 70 mm x 70 mm (recommended)

- Threshold setting: by means of reference samples according ISO 20567-1

- Available vision system for evaluation of chipped samples

- Quantiz can be used to analyze chipped samples and corrosion samples.

- For chipped samples Quantiz provides

- damaged area (specified in %)

- number of impacts

- Storage of numerical results together with image