CORROTHERM 610

Coatings & Industry > CORROSION > Salt Spray Cabinet

CORROTHERM 610

The CORROTHERM 610 is an extremely compact, space-saving corrosion tester with an all-plastic construction (polypropylene). It contains all the necessary equipment for carrying out the most common spray mist and condensation water tests according to the standards (DIN 50 021, DIN EN ISO 6270-2, DIN EN ISO 7253, ISO 11503, ASTM B 117, ASTM B 368 T "CASS TEST").

The volume of the cabinet is 400 litres.

The cabinet construction with a front door ensures simple operations and easy access to the testing area.

The spray nozzle is located on the inside of the rear wall so that the entire test space can be used for loading samples.

Within the test chamber itself is the storage tank for up to 100 litres (400 l Version) of spray solution.

This enables the test apparatus to work over the weekend without supervision.

The Corrosion Test Apparatus of the CORROTHERM 610 series is manually operated.

Clearly arranged buttons are available for functions such as the salt spray test, condensation water test and vapour evacuation.

Via the control buttons, which are at eye level, the temperature display, time switch, and the test duration display functions are available and also permits the automatic switch off function on completing the pre-programmed test time (i.e. 240 h).

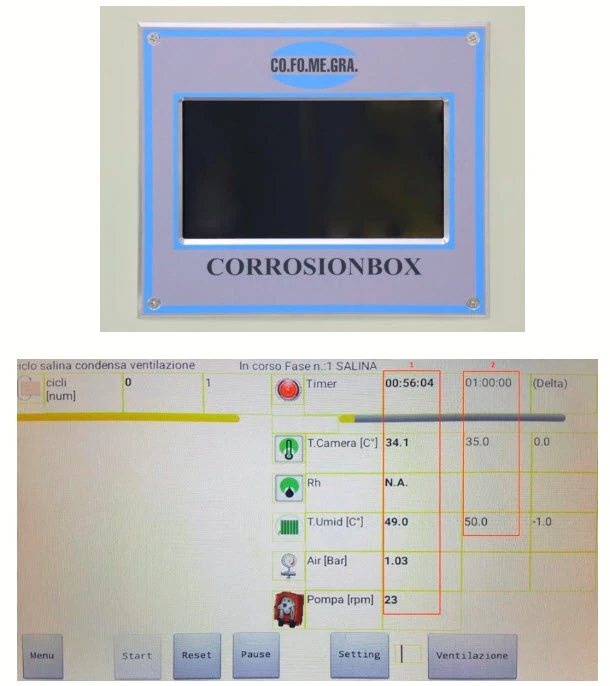

CORROTHERM 610e-PLUS

The CORROTHEM 610e-PLUS has the same

capacity as Model 610, but is operated

with a microcontroller.

Free programming of different test programs, inputs via touch screen control panel and

easy to use structure

of the menu.

Test status is continuously displayed on the large 7” display.

Control and monitoring of test chamber and humidifier temperature, monitoring of nozzle air

pressure and dosing pump RPH.

Self-diagnostic including warning messages, alarm messages and safety shut down.

Complete test report: chamber and humidifier temperature, nozzle air pressure and dosing pump RPH are periodically measured and stored in the controller memory together with test interruptions or alarms. Ethernet interface for PC connection.

CORROTHERM 610/610e-PLUS

400 l 1000 l

Capacity in l (approx.) 400 1000

Dimensions (W x D x H) in mm 1320 x 820 x 1450 1640 x 920 x 1800

Dimensions without dome 800 x 700 x 800 1100 x 800 x 1140

area (W x D x H) in mm

Net weight in kg (approx.) 168 300Capacity of test panels (approx.) 80 150

Test temperature range in °C from ambient temperature up to +50

Capacity of salt solution in l (approx.) 110 260

Power supply 230 V/AC, 50/60 Hz

Power consumption in VA (approx.) 2100 3500

Compressed air supply in bar,

approx. 5 - 8 Nm³/h 4 - 6 4 - 6

Water supply in bar (water de-mineralised),

approx. 1l/h 2 - 4 2 - 4

CORROTHERM 610/610e-PLUS

Order No. Description

101-01830131 CORROTHERM 610

test chamber volume 400 l incl. 3 specimen holders for weathering panels

101-01830231 Corrosion Test Apparatus CORROTHERM 610e-PLUS test chamber volume 400 l

incl. 3 specimen holders for weathering panels

101-01830331 Corrosion Test Apparatus CORROTHERM 610

test chamber volume 1000 l incl. 4 specimen holders for weathering panels

101-01830431 Corrosion Test Apparatus CORROTHERM 610e-PLUS test chamber volume 1000 l

incl. 4 specimen holders for weathering panels

Accessories

Specimen Holder for Weathering Panels

101-01830332 for 400 l version

101-01830432 for 1000 l version

101-01610232 Compressed Air Cleaning Unit

101-02240132 Condensate receptacle