200 mm Stainless Steel

Laboratory Product > TEST SIEVES

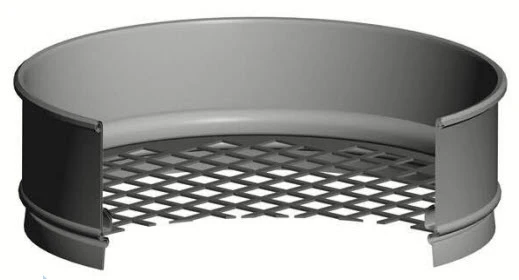

TEST SIEVE 200mm Ø x 50mm H STAINLESS STEEL FRAME

The sieve recommended by ISO, AFNOR, ASTM, BS, DIN, UNE standards.

Suitable for wet sieving.

Each sieve is laser marked with a serial number to ensure traceability.

Delivered with a Certificate of Compliance according to 2.1 EN 10204.Mirror polished. Frame material: AISI-304.

Weight: From 300 grams to 500 grams depending on the mesh opening.

Recommended sample volumes depending on the opening:

Opening Volume Opening Volume Opening Volume

38 µ 25 cm³ 125 µ 50 cm³ 2.00 mm. 200 cm³

45 µ 30 cm³ 250 µ 70 cm³ 4.00 mm. 350 cm³

63 µ 35 cm³ 500 µ 100 cm³ 8.00 mm. 500 cm³

90 µ 40 cm³ 1.00 mm 140 cm³ 16.00 mm 1000 cm

200.1 WIRE MESH SIEVES

200mm Ø x 50mm H STAINLESS STEEL FRAMEISO ASTM Ref. ISO ASTM Ref. ISO ASTM Ref. ISO ASTM Ref.

3310.1 E-11-2013 3310.1 E-11-2013 3310.1 E-11-2013 3310.1 E-11-2013

20 µ Nº 635 0800601 160 µ 0804801 1,00 mm Nº 18 0809001 11.20 mm 7/16 in 0814601

25 µ Nº 500 0800801 180 µ Nº 80 0805001 1,12 mm 0809201 12.50 mm ½ in. 0814801

32 µ Nº 450 0801001 200 µ 0805201 1,18 mm Nº 16 0809401 13.20 mm 0.530 in . 0815001

36 µ 0801201 212 µ Nº 70 0805401 1,25 mm 0809601 14.00 mm 0815201

38 µ Nº 400 0801401 224 µ 0805601 1,40 mm Nº 14 0809801 16.00 mm 5/8 in. 0815401

40 µ 0801601 250 µ Nº 60 0805801 1,60 mm 0810001 18.00 mm 0815601

45 µ Nº 325 0801801 280 µ 0806001 1,70 mm Nº 12 0810201 19.00 mm 3/4 in. 0815801

50 µ 0802001 300 µ Nº 50 0806201 1,80 mm 0810401 20.00 mm 0816001

53 µ Nº 270 0802201 315 µ 0806401 2,00 mm Nº 10 0810601 22.40 mm 7/8 in. 0816201

56 µ 0802401 355 µ Nº 45 0806601 2,24 mm 0810801 25.00 mm 1.00 in. 0816401

63 µ Nº 230 0802601 400 µ 0806801 2,36 mm Nº 8 0811001 26.50 mm 1.06 in. 0816601

71 µ 0802801 425 µ Nº 40 0807001 2,50 mm 0811201 28.00 mm 0816801

75 µ Nº 200 0803001 450 µ 0807201 2,80 mm Nº 7 0811401 31.50 mm 0817001

80 µ 0803201 500 µ Nº 35 0807401 3,15 mm 0811601 35.50 mm 1 1/4 in. 0817201

90 µ Nº 170 0803401 560 µ 0807601 3,35 mm Nº 6 0811801 37.50 mm 1 1/2 in. 0817401

100 µ 0803601 600 µ Nº 30 0807801 3,55 mm 0812001 40.00 mm 0817601

106 µ Nº 140 0803801 630 µ 0808001 4,00 mm Nº 5 0812201 45,00 mm 1 3/4 in 0817801

112 µ 0804001 710 µ Nº 25 0808201 4.50 mm 0812401 50.00 mm 2.00 in. 0818001

125 µ Nº 120 0804201 800 µ 0808401 4.75 mm Nº 4 0812601 53.00 mm 2.12 in. 0818201

140 µ 0804401 850 µ Nº 20 0808601 5.00 mm 0812801 56.00 mm 0818401

150 µ Nº 100 0804601 900 µ 0808801 5.60 mm Nº 3½ 0813001 63.00 mm 2 1/2 in 0818601

6.70 mm 0.265 in 0813401 75.00 mm 3.00 in. 0819001

7.10 mm 0813601 80.00 mm 0819201

8.00 mm 5/16 in. 0813801 90.00 mm 3 1/2 in. 0819401

9.00 mm 0814001 100.00 mm 4.00 in. 0819601

9.50 mm 3/8 in. 0814201 106.00 mm 4.24 in. 0819801

10.00 mm 0814401 112.00 mm 0820001

125.00 mm 5.00 in 0820201

200.2 SIEVES WITH PERFORATED PLATE

200mm Ø x 50mm H STAINLESS STEEL FRAME

Square holes

The sieves with perforated plates included in this list strictly comply with the quality criteria required by ASTM E-323 and ISO 3310.2, as well as with regard to openings and distances between centres and thicknesses.

To avoid partial perforations with possible error in the screening result, the plates are not perforated in the area in contact with the frame.

The standard EN 933-2 recommends the use of sieves with square perforated plates (according to ISO 3310.2), when the opening is 4 mm. or more.

Material of the perforated plates Stainless steel AISI-304

200.3 SIEVES WITH PERFORATED PLATE

200mm Ø x 50mm H STAINLESS STEEL FRAME

The sieves with the perforations 0.50 mm Ø, 1.00 mm Ø, 1.80 mm Ø, 4.00 mm Ø and 4.50 mm Ø are used for testing :

- rapeseed,

- rice,

- soybean

- and other cereals.

Material of the perforated plates Stainless steel AISI-304

200.4 SIEVES WITH PERFORATED PLATE

200mm Ø x 50mm H STAINLESS STEEL FRAME

Elongated holes

The sieves mounted with elongated perforated plates are completely made of AISI-304 stainless steel.

Their main field of application is the grain and cereal industry.

To obtain total accuracy in the tests, the plates are not perforated in the area in contact with the frame, which avoids partial holes that could potentially falsify the results.

200.5 SIEVES WITH ELECTROFORMED

PLATES

Square holes

Sieves with electroformed sheets have much smaller tolerances

than sieves with wire mesh.

The tolerance for this type of sieve is

+/- 2%.

Compared to sieves with metal mesh, this tolerance is

two to ten times higher, depending on the size of the opening.

These sieves with electroformed plates are used both for

small sample sizes and for special materials, and above all

for high-precision quality control. Each sieve is delivered

with a certificate of conformity.

Due to the high price, compared to sieves with wire mesh, their use is limited to applications where the

special qualities of the sieves are required. Sieves with electroformed plates are precision instruments

that have to be treated with care.