0/45

Coatings & Industry > Color > Portable

Erichsen Color and Gloss Unit SPEKTROMASTER 565-45

for simultaneous measurement of color (geometry 45/0, aperture 11 mm) and gloss (geometry 60°, aperture 5 x 10 mm) in accordance with DIN, ISO and ASTM.

Purpose and Application

The overall appearance of a product is influenced by color and gloss. A sample of the same color but higher gloss level is visually perceived darker and more saturated than a low gloss sample. In order to get a uniform appearance, both attributes need to be controlled.

With the new SPEKTROMASTER you can measure any color: dark - brilliant - steep reflectance curves.

The 10 nm spectral resolution not only ensures highly precise color results, but also an excellent agreement with competitive color instruments - even bench-top units.

The Spectrometers of the very most other suppliers are only able to measure the color value.

In comparison with this, the SPEKTROMASTER 565 is able to measure color and gloss both simultaneously!

Thus, the cause of a mismatch can be clearly defined in any situation.

- Color and 60° gloss are displayed at the same time

- In compliance with international specifications

- Tolerances for color and gloss allow quick pass/fail decisions in production

45°/0° For measurements due to the allusion to a visually valued impression.

Also for a lot of Automotive relevant applications as well as oftentimes for measurements within the final inspection.

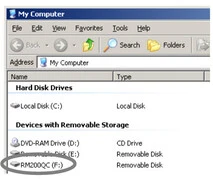

X Rite CAPSURE™ RM200QC Portable Spectrophotometer

Overview

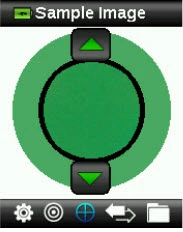

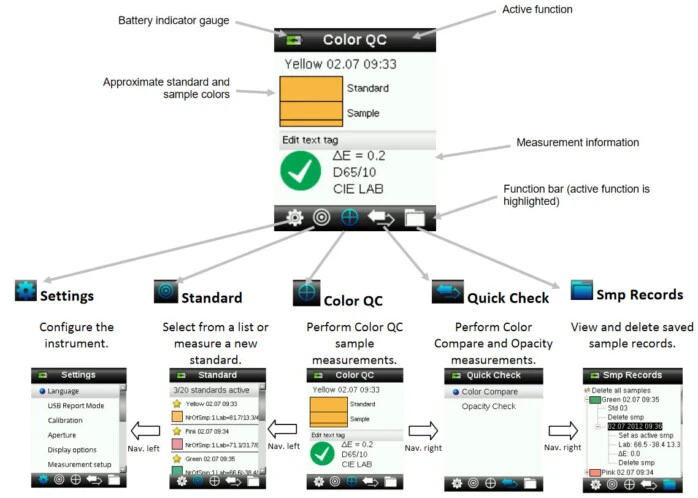

The X-Rite RM200QC Imaging Spectrocolorimeter is a handheld unit that simplifies color measurement from incoming material to outgoing product shipments.

It is designed to provide stable color comparisons for materials and products wherever color control is important.

It is an elegant, portable instrument that fits comfortably in your hand or pocket to take with you wherever you go – from the quality control lab to the manufacturing floor to supplier inspections in the field.

Key Benefits

The X-RiteRM200QC, is an handheld spectrocolorimeter that provides an inexpensive yet powerful way to record and communicate color difference to speed introduction of new products and reduce instances of scrap.

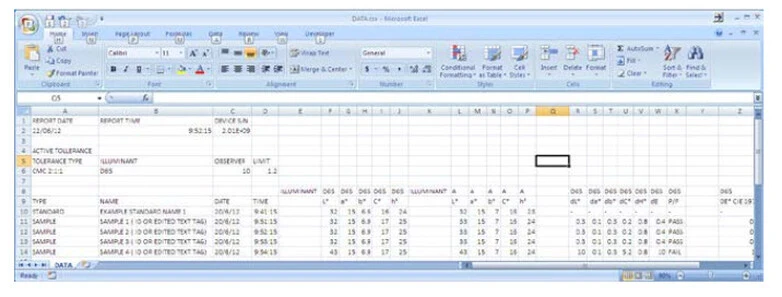

It simplifies how textiles, coatings, plastic molding and other industries can compare color parts in production with set standards, and then create reports.

When color requirements are stringent, relying solely on visual evaluation and comparison to physical color swatches can be problematic, as they can be damaged or deteriorate over time.

In addition, since everyone sees color differently, and color perception is affected by lighting and other conditions, using a color measurement instrument, such as the affordable RM200QC, removes uncertainty and boosts color quality.

The RM200QC was specifically designed with quality control professionals and production managers in mind.

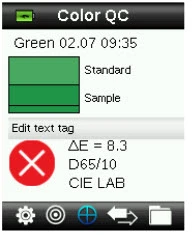

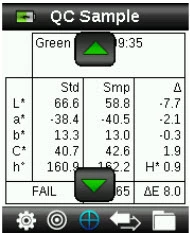

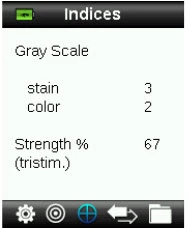

• Simply upload Pantone, Munsell or any other standards, set tolerances, and quickly see pass/fail indicators when measurements are taken, taking the emotion out of color evaluation and speeding customer approvals.

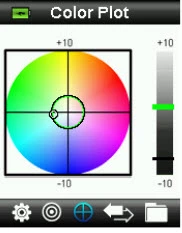

• Create and store up to 30 standards using the averaging function for highest accuracy. An easy-to-understand color plot shows the difference between the standard and the sample being measured.

• Eliminate issues related to staff experience; everyone uses the same convenient, reliable device with an easy pass/fail indication based on approved standards.

• Use the RM200QC to control variations between lab formulation production and final goods, including control of batch-to-batch variations during the manufacturing process, reducing waste and rework.

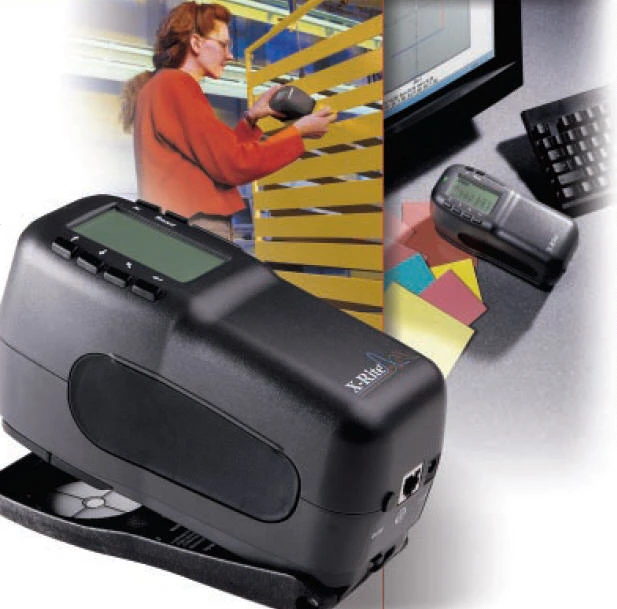

962 & 964 0°/45° Portable Spectrophotometer

The 962-964 Portable 0/45 Spectrophotometer allows you to obtain absolute and difference measurements in the lab, plant, or field for a wide range of colorimetric systems.

Accurate Color On the Go

The 962 portable handheld 0/45 spectrophotometer is a convenient color measurement instrument that allows you to obtain absolute and differential measurements in the lab, plant or field for a wide range of colorimetric systems. It is ideal for distributed workgroups whose members have varying requirements and skill levels but who must deliver color consistency across the supply chain.

The X-Rite 962 features an easy-to-read graphical LCD display and a pass/fail mode that measures against up to 1,024 standards with tolerances that can be stored for easy pass/fail measurement. Its unique Project Mode enables the collection of multiple color standards under an identified project as part of a corporate color standards program. The 962 is available in three models, distinguished by their measurement area: 962 (7mm), 962S (4mm), 962L (15mm).

Specifications 1

Short Term Repeatability - White : 0.10 ΔE*ab on white ceramic (Standard deviation)

Measurement Geometry : 0/45°

Inter-Instrument Agreement : 0.20 ΔE*ab avg.

Illumination Spot Size : 21.5mm or 9mm or 6.5mm

Lamp Life : Approx. 500,000 measurements

Light Source : Gas-filled tungsten lamp

Measurement Cycle Time : ≈ 2 seconds

Measurement Spot : 15mm or 7mm or 4mm

Measurement Time : ≈ 2 seconds

Photometric Range : 0 to 200%

Photometric Resolution : 0.01%

Spectral Analyzer : Blue-enhanced silicon photodiodes

Spectral Interval :10nm

Spectral Range : 400nm-700nm

Spectral Reporting : 10nm

Color Spaces : CIE XYZ, CIE Yxy, CIE LAB, Hunter LAB, CIE LCH,

Illuminants : A, C, D50, D65, D75, F2, F7, F11 & F12

Observers : 2° & 10°

Reflectance Aperture(s) : 1