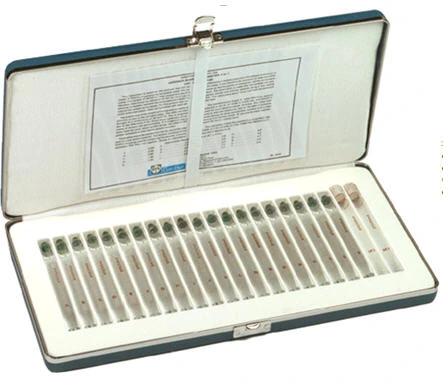

Dip Viscosity Cups

Purpose and Application

Rapid determination of the viscosity of any type of fluid, as for instance paint, varnish, wet enamel, photogravure ink, dye and lacquer for leather, oil, fat, foodstuff etc. Particularly suit-able in the workshop.

Measuring Principle

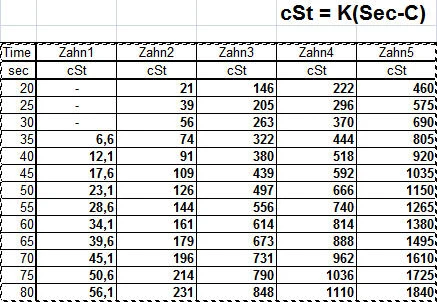

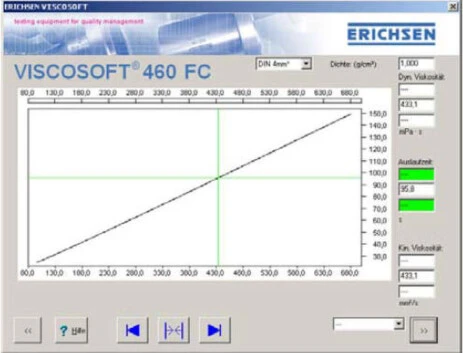

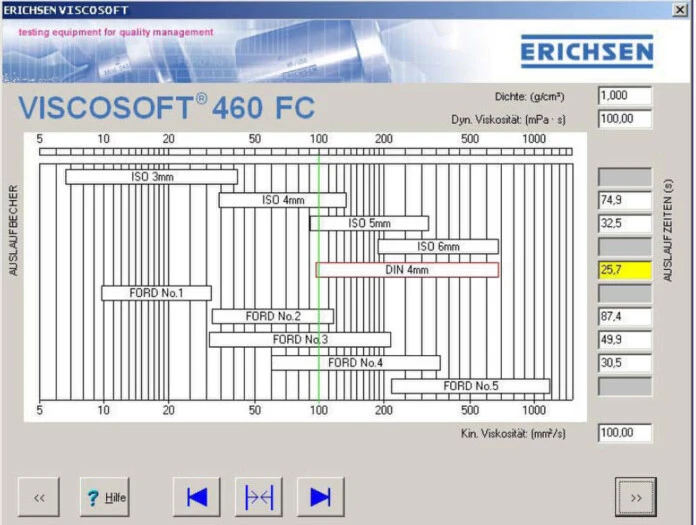

The viscosity of a substance to be determined is expressed as the efflux time of the measured volume (100 ml) out of a cup through an orifice of specified diameter. The efflux time is measured with a stop-watch.

FLOW CUP WITH HANDLE (FRIKMAR)

Thanks to its handle, this cup is very easy to use and performs quick controls in workshop or during manufacturing processes.

The instrument is first dipped into the product to be measured then emptied through the orifice. The flow time can be converted into cSt.

Several models, from 6 to 2000 cSt.

ASTM - DIN - EN - ISO - NF

- ASTM D 1200

- ASTM D 5125

- EN ISO 2431

Tube I.D. control: 0.1mm = 2% error