Model 606

Coatings & Industry > CORROSION > Salt Spray Cabinet

Corrosion Testing Apparatus, Model 606

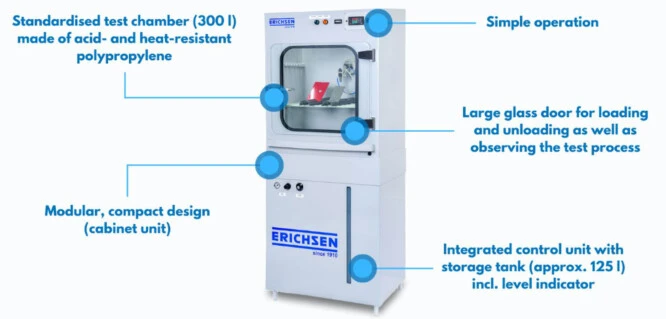

Corrosion Testing Equipment 606 / 300-Basic

The compact Corrosion Testing Instrument in modular design, Model 606-Basic / 300l, to perform salt spray and condensation tests, is made of impact resistant, eco-friendly polypropylene material.

It consists of a test chamber of 300 l capacity, and a built-in control unit as well as an integrated storage tank for approx. 125 l salt solution.

The control unit is equipped with the necessary control instruments.

The large, transparent access door allows easy mounting of specimens, which may e.g. be hung from the delivered sample rods, to be exposed to aggressive salt spray for a certain period of time.

A dosing pump serves for an infinitely variable adjustment to achieve optimum consumption of spray solution.

Corrosion Testing Apparatus, Model 606-1

The Corrosion Testing Apparatus, Model 606-1 consists of a control cabinet and one test chamber (optional order)

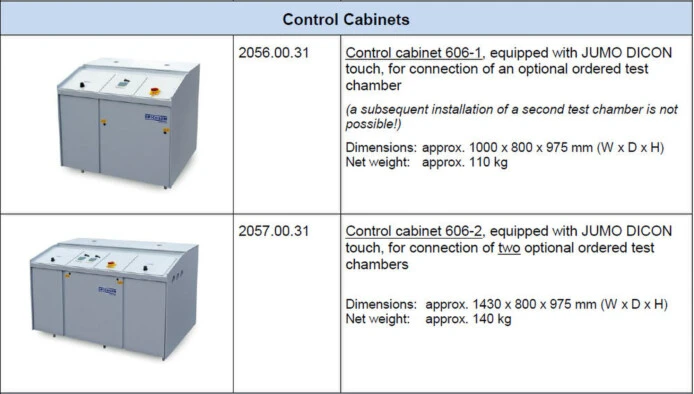

Order number: 2056.00.31

The control cabinet is equipped with JUMO DICON touch for easy operation and monitoring of the test equipment as well as the necessary regulating and control instruments for monitoring:

The control cabinet is equipped with JUMO DICON touch for easy operation and monitoring of the test equipment as well as the necessary regulating and control instruments for monitoring:

- the chamber temperature,

- the temperature of the humidifier,

- the spray pressure and

- the duration of the test.

The Corrosion Testing Apparatus, Model 606-1 is equipped with:

- pneumatic dome opening,

- function for tests in heat damp atmospheres,

- one dosing pump for optimum setting for the salt solution to be sprayed,

- an integrated 200 l solution reservoir and

- one circulation pump.

Further scope of supply:

- 3 specimen holders

- 2 condensate receptacles

Corrosion Testing Apparatus, Model 606-2

Order number: 2057.00.31

The Corrosion Testing Apparatus, Model 606-2 consists of a control cabinet and two test chambers (optional order)

The control cabinet is equipped with JUMO DICON touch for easy operation and monitoring of the test equipment as well as the necessary regulating and control instruments for monitoring:

- the chamber temperature,

- the temperature of the humidifier,

- the spray pressure and

- the duration of the test.

The Corrosion Testing Apparatus, Model 606-2 is equipped with:

- pneumatic dome opening,

- function for tests in heat damp atmospheres,

- two dosing pumps for optimum setting for the salt solution to be sprayed,

- two integrated 150 l (each) solution reservoirs and

- two circulation pumps.

Further scope of supply:

- 6 specimen holders

- 4 condensate receptacles

Order number: 2006.00.32

Test Chamber with circular design and 400 l test chamber volume.

For use with the control cabinets for Corrosion Testing Apparatus, Model 606-1 and 606-2.

For use with the control cabinets for Corrosion Testing Apparatus, Model 606-1 and 606-2.

Order number: 2010.00.32

Test chamber in rectangular design with 400 l test chamber volume.

For use with the control cabinets for Corrosion Testing Apparatus, Model 606-1 and 606-2.

Test Chamber 606, circular design 1000 l

Order number: 2005.00.32

Test chamber in circular design with 1000 l test chamber volumen.

For use with the control cabinets for Corrosion Testing Apparatus, Model 606-1 and 606-2.

For use with the control cabinets for Corrosion Testing Apparatus, Model 606-1 and 606-2.

Order number: 2009.00.32

Test chamber in rectangular desig with 1000 l test chamber volume.

For use with the control cabinets for Corrosion Testing Apparatus, Model 606-1 and 606-2.

Order number: 2049.00.32

Test chamber in rectangular design with 2000 l test chamber volume.

For use with the control cabinets for Corrosion Testing Apparatus, Model 606-1 and 606-2.

Design

The ERICHSEN Corrosion Testing Instrument, Model 606, take full advantage of our wide experience in the construction of all kinds of testing equipment as well as of the information and worldwide feedback received from users. Made of impact resistant, eco-friendly polypropylene material each instrument forms a closed unit.

Our corrosion testing instruments can be compiled individually by the user.

For this purpose, two control cabinets are available, either for the equipment with one test chamber (Model 606-1) or as double chamber device (Model 606-2).

Various test chamber sizes with test volume of 400 l, 1000 l or 2000 l can be selected regarding the requirements.

The test chambers (400 l and 1000 l) are available in circular and rectangular design.

The circular design provides even distribution of the salt solution vapour over the entire test zone.

When tests are required on larger working parts, it is often not possible to employ a test chamber of circular symmetry. For this reason, as an alternative, rectangular test chambers with a capacity of up to 2000 l (special dimensions upon request) can be supplied.

The scope of supply includes an equipment for tests in heat damp atmospheres according to DIN EN ISO 6270-2 (CH) as well as two condensate receptacles.

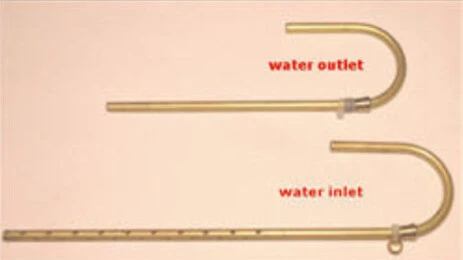

The top of the test chamber dome is pneumatically opened and closed so that both hands can be used to lodge the specimens. A dosing pump serves for an infinitely variable adjustment to achieve optimum consumption of spray solution. The large storage tank for approx. 200 l salt solution allows continuous testing without attention over a period of up to a week.

A circulation pump for mixing the salt solution in the storage tank is permanently installed in the lower part of the control unit.

Constructed similarly to the control cabinet 606-1, the control cabinet 606-2 (for connection of two test chambers) is equipped with two dosing pumps and two circulation pumps. There are two integrated storage reservoirs for spraying liquid (each 150 l). The package includes four condensate receptacles.

The scope of supply includes 3 specimen holder for weathering panels (per test chamber), with test capabilities of 18 test panels per specimen holder.

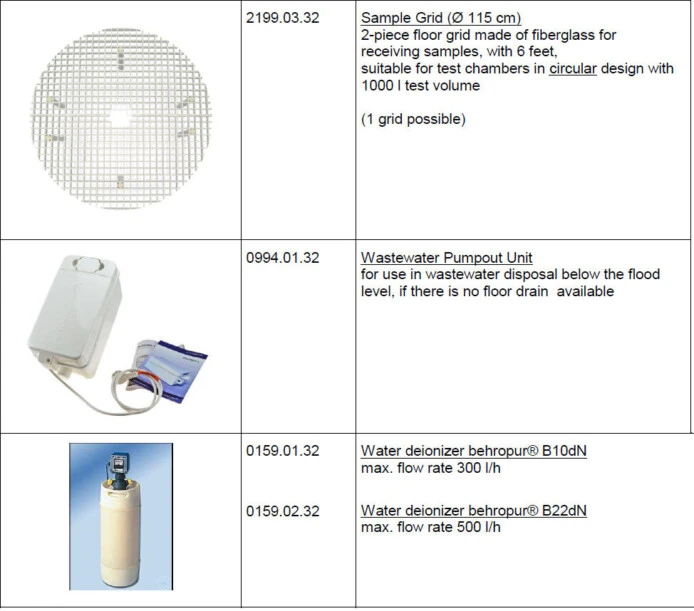

Accessories (optional)

- Software JUMO PCC/PCA consisting of analysis software and communicationsoftware as well as a „Standard OnlineVisualization“ called with a conventional browser(prerequisite: operating system Microsoft Windows and Silverlight).

- Specimen holders for bulky parts

- Wastewater pumpout unit

- Compressed air maintenance unit

- Water

- Salt

Technical Data

Power supply 400 V / 3~ / 50 Hz (other voltages on request)

Consumption 400 l test chamber approx. 3820 VA

1000 l test chamber approx. 4320 VA

2000 l test chamber approx. 5320 VA

Compressed air connection Air pressure 5 - 7 bar

Air consumption 15 l/min at 6 bar

Water pipe connection Pressure 2 - 6 bar

Test temperature range from ambient temperature up to +50 °C

Floor load of the test chamber max. approx. 300 kg

(special versions on request )

Capacity of the test chamber

400 l test chamber approx. 100 test panels

1000 l test chamber approx. 180 test panels

2000 l test chamber approx. 400 test panels

(depending on the shape)