Tools 2

Coatings & Industry > CORROSION > Specimen preparation

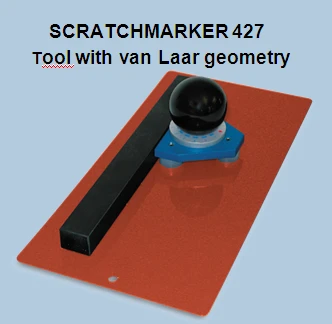

Scratching Tool, SCRATCHMARKER 427

Purpose and Application

The SCRATCHMARKER 427 serves to apply defined scratches through coatings on specimen panels used for corrosion tests (e. g. in the ERICHSEN Corrosion Test Instruments, Models 519, 606 or 608).

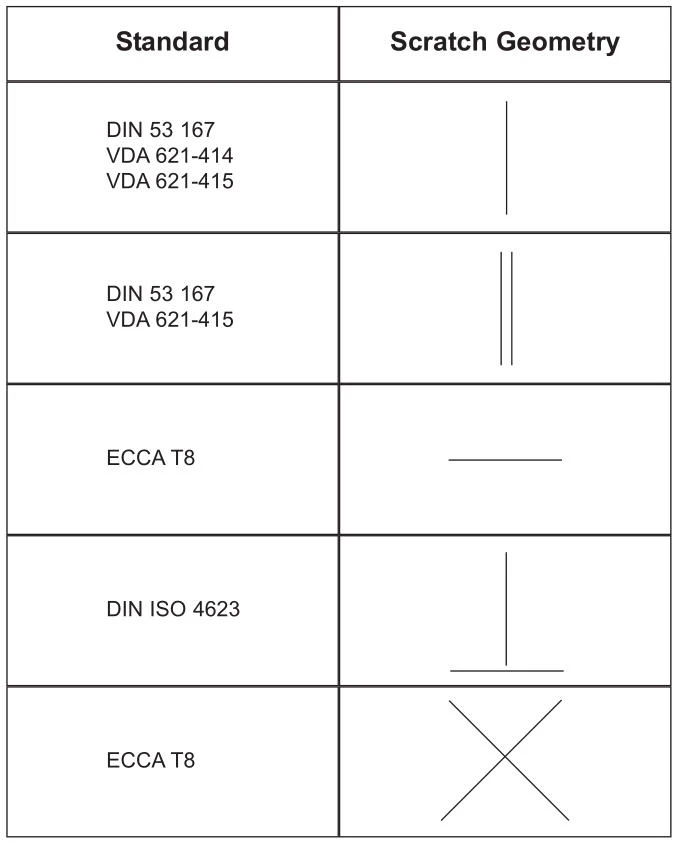

According to the various standards different scratch pattern are produced. In the following table the most usual corrosion test standards as well as the relevant scribed marks are shown.