SHORE - IRHD

Metal Testing > Hardness Testers > AFFRI > For Plastic

Hardness testers for plastic and rubber

Automatic hardness testers, portables or bench top, for Shore and IRHD hardness methods in compliance with ASTM and ISO standards.

Easy measure on plastic and rubber materials and synthetic fibers.

SHORE

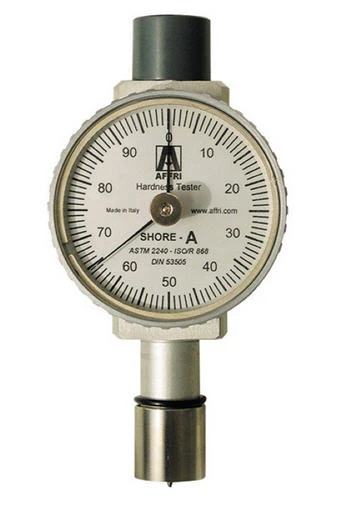

SHORE - Portable hardness tester for rubber, plastic, medical components, paper, sponge.

Shore A - B - C - D - D0 - 0 - 00 - E - M - 000 - 000S

Portable hardness tester in compliance with ASTM 2240, ISO R.868, DIN 53505, JIS K7215 standards.

Slim measuring nose to ensure exact measurement also on small components.

Suitable for tires, roll, for soft flexible rubber, plastic, PVC, polyester, neoprene, leather, thiokol, nitril rubbers, etc.

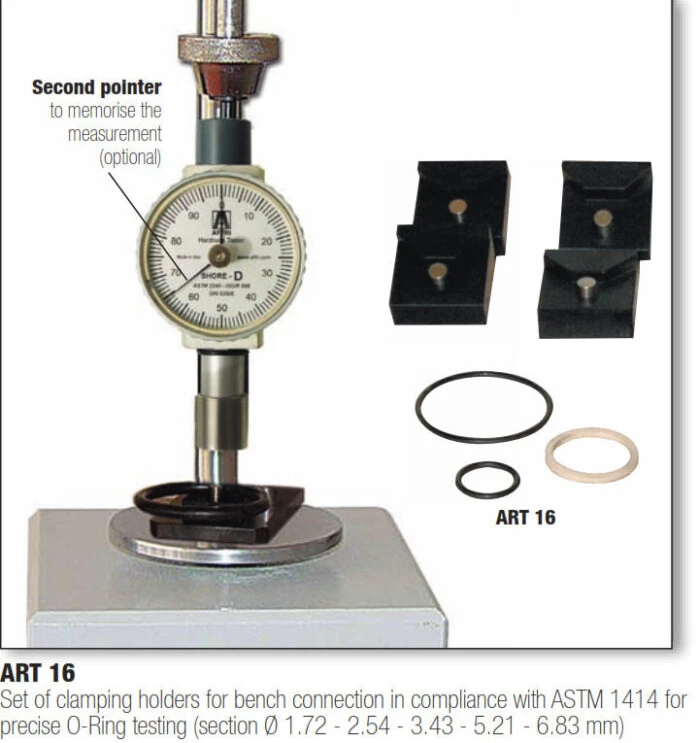

Optional clamping system to apply a constant and vertical pressure on all test piece, also on curved surfaces assuring accurate results

Optional clamping system to apply a constant and vertical pressure on all test piece, also on curved surfaces assuring accurate results

The tester can be installed on the relative bench support for laboratory purpose.

ELECTRONIC SHORE

SHORE - Portable hardness tester for rubber, plastic, medical components, paper, sponge.

Shore A - B - C - D - D0 - 0 - 00 - E - M - 000 - 000S

Portable hardness tester in compliance with ASTM 2240, ISO R.868, DIN 53505, JIS K7215 standards.

Slim measuring nose to ensure exact measurement also on small components.

Suitable for tires, roll, for soft flexible rubber, plastic, PVC, polyester, neoprene, leather, thiokol, nitril rubbers, etc.

Optional clamping system to apply a constant and vertical pressure on all test piece, also on curved su

Optional clamping system to apply a constant and vertical pressure on all test piece, also on curved su

rfaces assuring accurate results.The tester can be installed on the relative bench support for laboratory purpose.

Models | Fields of application |

| 3001 - Shore A | For soft, flexible rubber, plastic, PVC, polyester, neoprene, leather, thiokol, nitril rubbers, tyres, etc |

| 3011 - Shore B | As A scale for high values |

| 3004 - Shore C | As D scale for low values |

| 3002 - Shore D | Scale for hard and rigid surfaces synthetic materials, acrilics,

plexiglass, printing rolls, cellulose, acetates, densified wood, nylon,

derling, ceramic and composit |

| 3010 - Shore DO | As B and C |

| 3009 - Shore O | As A scale for low values |

| 3008 - Shore OO | For sponges, natural rubber and silicon |

| 3013 - Shore E | ASTM D 2240 - 02 a |

| 3014 - Shore M | ASTM D 2240 - 02 a |

| 3015 - Shore 000 | ASTM D 2240 - 02 a |

| 3016 - Shore 000-S | ASTM D 2240 - 02 a |

IRHD

Bench top hardness tester for automatic hardness measurements on plastic, rubber and synthetic fibers.

IRHD, Micro IRHD, Shore A, D, O, OO. In compliance with ASTM 48 / ASTM 1415 / ISO 7318 / DIN 53519-2 standards.The measurement cycle and the physical contact with the sample by the indenter are managed by the software with phase control by load cells in closed loop load control (patent AFFRI) this eliminates manual errors and the influences of external vibrations.

With a single motion the tester automatically descends toward the sample locking it and then performs the hardness test measurement cycle.

Test measurements that are fully controlled by the computer eliminates human error and increases the accuracy, repeatability and reproducibility of the measurements.

The Anvil specimen holder can accommodate predetermined sample holder for each chord dimension of 'OR’ according to ASTM 1414 without having to perform manual settings.

The measurements are stored in the computer hard drive and analyzed for statistical processes.

The Anvil specimen holder can accommodate predetermined sample holder for each chord dimension of 'OR’ according to ASTM 1414 without having to perform manual settings.

The measurements are stored in the computer hard drive and analyzed for statistical processes.

IRHD / MICRO IRHD | ||

| Standards | ASTM 48 / ASTM 1415 / ISO 7318 / DIN 53519-2 | |

| Elevating screw stroke | 215 mm | |

| Depth capacity | 190 mm | |

| Indenter and clamping hood stroke | 10 mm | ---- |

| Methods | L (10 ÷ 35), N (30 ÷ 95), H (85 ÷ 100) | M (35 ÷ 85) |

| Feasible tests | IRHD | MICRO IRHD |

| Accuracy | Better than 0,5% | |

MICRODAKO

MICRODAKO is a fully motorized hardness tester which determinate the hardness of thermoplastic, rubber and vulcanized rubber samples, in accordance to standardized methods IRHD and Shore.

High-defnition of 0.1 IRHD.

Load forces are easily selected from the PC and are automatically applyed trough load cells with elecronic controlled in Closed Loop. (Pat. AFFRI)

MICRODAKO is equipped with a touchscreen PC support and a powerful software to control the entire instrument: from the configuration of the test, to the complete management of statistics.

MICRODAKO can be configured with a wide range of accessories according to customer requirements.

Load forces are easily selected from the PC and are automatically applyed trough load cells with elecronic controlled in Closed Loop. (Pat. AFFRI)

MICRODAKO is equipped with a touchscreen PC support and a powerful software to control the entire instrument: from the configuration of the test, to the complete management of statistics.

MICRODAKO can be configured with a wide range of accessories according to customer requirements.

TECHNICAL FEATURES | MICRODAKO 2S/5S |

Standards | ISO 48, 7318, 7619, ASTM 1415, ASTM 2240, UNI EN 954-1, UNI EN 292-2, UNI EN 349, UNI EN 418, BS 903, CEI EN 60204-1, DIN 53 519-1/2 |

Vertical Stroke | Motorized 150 mm |

Depth capacity | 75 mm |

Methods | L (10 ÷ 35), N (30 ÷ 95), H (85 ÷ 100) M (35 ÷ 85) |

Feasible tests | IRHD MICRO IRHD SHORE |

Accuracy | Better than 0,5% |