CALIBRATED HARDNESS TEST BLOCKS

Metal Testing > Hardness Testers > AFFRI > ACCESSORIES

CERTIFIED HARDNESS TEST BLOCKS FOR INSTRUMENT CALIBRATION

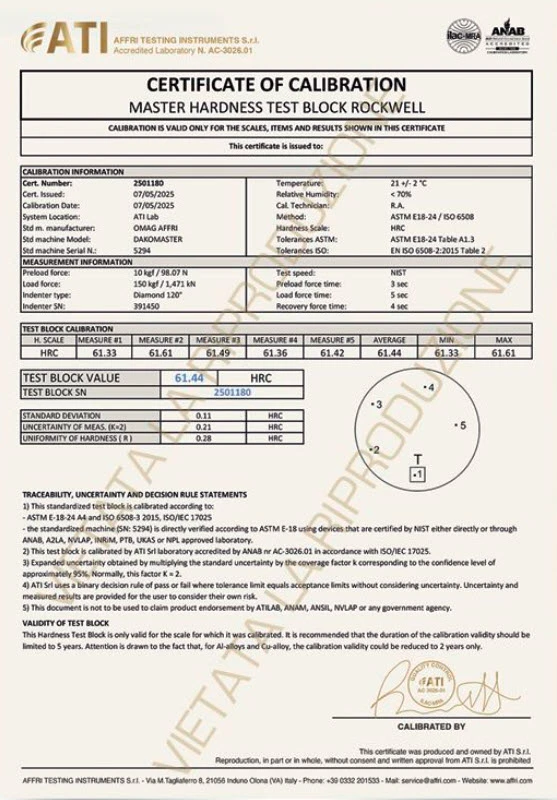

ISO/IEC 17025 Accredited

ISO/IEC 17025 Accredited

ATI provides certified hardness test blocks for calibrating Rockwell, Brinell, Vickers, and Knoop hardness testers, ensuring full compliance with ASTM and ISO standards.

Our test blocks are available in a wide range of hardness values to meet diverse calibration requirements.

Each block is certified through our ISO/IEC 17025-accredited laboratory (ANAB n. AC 3026.01) and benefits from ILAC-MRA recognition.

Rigorous quality controls guarantee outstanding precision and traceability. Choose AFFRI TESTING INSTRUMENTS for reliable, high-accuracy calibration specimens.

Types of Calibrated Master Hardness Test Blocks

- Rockwell Test Blocks – HRB, HRC, HR15N, etc.

- Brinell Test Blocks – HBW10/3000, HBW5/750, HBW2.5/62.5, etc.

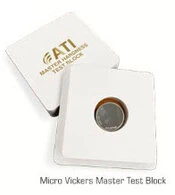

- Vickers and Microhardness Blocks – HV0.1, HV0.5, HV1, HV10, ecc.

- Knoop Blocks – HK0.1, HK0.5, HK1, HK2, ecc.

Applications and Industries

Our certified hardness test blocks are used by calibration laboratories, quality control departments, and manufacturers in industries such as aerospace, automotive, medical, and metallurgical production.

Why Choose ATI Test Blocks?

- ISO/IEC 17025 and ILAC-MRA accredited

- Custom calibration values available upon request

- Reliable certification with full traceability

Hardness Scale Hardness Range Size mm with mirror surface Weight

HRA 20 < HRA < 40 Ø 60X10 mm 0,2 kg

45 < HRA < 75 Ø 60X10 mm 0,2 kg

80 < HRA < 84 Ø 60X10 mm 0,2 kg

HRB 20 < HRB < 50 50X50 mm** 0,2 kg

60 < HRB < 70 60X40 mm 0,2 kg

88 < HRB < 100 60X40 mm 0,2 kg

HRC 20 < HRC < 30 Ø 60X10 mm 0,2 kg

35 < HRC < 55 Ø 60X10 mm 0,2 kg

60 < HRC < 70 Ø 60X10 mm 0,2 kg

HRD* 40 < HRD < 47 Ø 60X10 mm 0,2 kg

55 < HRD < 63 Ø 60X10 mm 0,2 kg

70 < HRD < 75 Ø 60X10 mm 0,2 kg

HRE 95 < HRE < 100 Ø 60X10 mm 0,2 kg

107 < HRE < 114 Ø 60X10 mm 0,2 kg

HRF 105 < HRF < 114 Ø 60X10 mm 0,2 kg

HR15N 70 < HR15N < 77 Ø 60X10 mm 0,2 kg

78 < HR15N < 88 Ø 60X10 mm 0,2 kg

89 < HR15N < 91 Ø 60X10 mm 0,2 kg

HR30N 42 < HR30N < 54 Ø 60X10 mm 0,2 kg

55 < HR30N < 73 Ø 60X10 mm 0,2 kg

74 < HR30N < 80 Ø 60X10 mm 0,2 kg

HR45N 20 < HR45N < 31 Ø 60X10 mm 0,2 kg

32 < HR45N < 61 Ø 60X10 mm 0,2 kg

62 < HR45N < 70 Ø 60X10 mm 0,2 kg

HR15T 77 < HR15T < 80 Ø 60X10 mm 0,2 kg

80 < HR15T< 83 Ø 60X10 mm 0,2 kg

88 < HR15T < 93 Ø 60X10 mm 0,2 kg

HR30T 49 < HR30T < 56 Ø 60X10 mm 0,2 kg

57 < HR30T < 63 Ø 60X10 mm 0,2 kg

73 < HR30T < 82 Ø 60X10 mm 0,2 kg

HR45T 23 < HR45T < 33 Ø 60X10 mm 0,2 kg

34 < HR45T < 43 Ø 60X10 mm 0,2 kg

58 < HR45T < 72 Ø 60X10 mm 0,2 kg

** The HRB (20 < HRB < 50) master test block has a square shape.

*These master hardness test blocks are subject to availability

Hardness Scale Hardness Range Size mm with mirror surface Weight

HBW 10/3000 150 < HBW < 225 Ø 90X17 mm 0,8 kg

225 < HBW < 350 Ø 90X17 mm 0,8 kg

350 < HBW < 650 Ø 90X17 mm 0,8 kg

HBW 10/1500* 150 < HBW < 225 Ø 90X17 mm 0,8 kg

225 < HBW < 350 Ø 90X17 mm 0,8 kg

350 < HBW < 650 Ø 90X17 mm 0,8 kg

HBW 10/1000 75 < HBW < 150 Ø 90X17 mm 0,8 kg

150 < HBW < 300 Ø 90X17 mm 0,8 kg

300 < HBW < 450 Ø 90X17 mm 0,8 kg

HBW 10/500 75 < HBW < 150 Ø 90X17 mm 0,8 kg

150 < HBW < 300 Ø 90X17 mm 0,8 kg

300 < HBW < 450 Ø 90X17 mm 0,8 kg

HBW 10/250* 75 < HBW < 150 Ø 60X10 mm 0,2 kg

150 < HBW < 300 Ø 60X10 mm 0,2 kg

300 < HBW < 450 Ø 60X10 mm 0,2 kg

HBW 10/100* 75 < HBW < 125 Ø 60X10 mm 0,2 kg

HBW 5/750 100 < HBW < 225 Ø 90X17 mm 0,8 kg

225 < HBW < 350 Ø 90X17 mm 0,8 kg

350 < HBW < 650 Ø 90X17 mm 0,8 kg

HBW 5/250* 75 < HBW < 150 Ø 60X10 mm 0,2 kg

150 < HBW < 300 Ø 60X10 mm 0,2 kg

300 < HBW < 450 Ø 60X10 mm 0,2 kg

HBW 5/125* 75 < HBW < 150 Ø 60X10 mm 0,2 kg

150 < HBW < 300 Ø 60X10 mm 0,2 kg

300 < HBW < 450 Ø 60X10 mm 0,2 kg

HBW 5/62,5* 75 < HBW < 150 Ø 60X10 mm 0,2 kg

150 < HBW < 300 Ø 60X10 mm 0,2 kg

300 < HBW < 450 Ø 60X10 mm 0,2 kg

HBW 2.5/187.5 100 < HBW < 225 Ø 90X17 mm 0,8 kg

225 < HBW < 350 Ø 90X17 mm 0,8 kg

350 < HBW < 650 Ø 90X17 mm 0,8 kg

HBW 2.5/62.5 75 < HBW < 150 Ø 60X10 mm 0,2 kg

150 < HBW < 300 Ø 60X10 mm 0,2 kg

300 < HBW < 450 Ø 60X10 mm 0,2 kg

Hardness Scale Hardness Range Size mm with mirror surface Weight

HV2* 200 < HV2 < 350 Ø 60X10 mm 0,2 kg

350 < HV2 < 450 Ø 60X10 mm 0,2 kg

450 < HV2 < 750 Ø 60X10 mm 0,2 kg

HV30* 200 < HV3 < 350 Ø 60X10 mm 0,2 kg

350 < HV3 < 450 Ø 60X10 mm 0,2 kg

450 < HV3 < 750 Ø 60X10 mm 0,2 kg

HV5 175 < HV5 < 350 Ø 60X10 mm 0,2 kg

350 < HV5 < 450 Ø 60X10 mm 0,2 kg

450 < HV5 < 750 Ø 60X10 mm 0,2 kg

HV10 175 < HV10 < 350 Ø 60X10 mm 0,2 kg

350 < HV10 < 450 Ø 60X10 mm 0,2 kg

450 < HV10 < 750 Ø 60X10 mm 0,2 kg

HV20* 175 < HV20 < 350 Ø 60X10 mm 0,2 kg

350 < HV20 < 450 Ø 60X10 mm 0,2 kg

450 < HV20 < 750 Ø 60X10 mm 0,2 kg

HV30 175 < HV30 < 350 Ø 60X10 mm 0,2 kg

350 < HV30 < 450 Ø 60X10 mm 0,2 kg

450 < HV30 < 750 Ø 60X10 mm 0,2 kg

HV50* 175 < HV50 < 350 Ø 60X10 mm 0,2 kg

350 < HV50 < 450 Ø 60X10 mm 0,2 kg

450 < HV50 < 750 Ø 60X10 mm 0,2 kg

HV100* 175 < HV100 < 350 Ø 60X10 mm 0,2 kg

350 < HV100 < 450 Ø 60X10 mm 0,2 kg

450 < HV100 < 750 Ø 60X10 mm 0,2 kg

Hardness Scale Hardness Range Size mm with mirror surface Weight

HV0.01* 200 < HV0.01 < 350 Ø 25X10 mm 0,1 kg

350 < HV0.01 < 450 Ø 25X10 mm 0,1 kg

450 < HV0.01 < 750 Ø 25X10 mm 0,1 kg

HV0.015* 200 < HV0.015 < 350 Ø 25X10 mm 0,1 kg

350 < HV0.015 < 450 Ø 25X10 mm 0,1 kg

450 < HV0.015 < 750 Ø 25X10 mm 0,1 kg

HV0.02* 175 < HV0.02 < 350 Ø 25X10 mm 0,1 kg

350 < HV0.02 < 450 Ø 25X10 mm 0,1 kg

450 < HV0.02 < 750 Ø 25X10 mm 0,1 kg

HV0.025* 175 < HV0.025 < 350 Ø 25X10 mm 0,1 kg

350 < HV0.025 < 450 Ø 25X10 mm 0,1 kg

450 < HV0.025 < 750 Ø 25X10 mm 0,1 kg

HV0.05* 175 < HV0.05< 350 Ø 25X10 mm 0,1 kg

350 < HV0.05 < 450 Ø 25X10 mm 0,1 kg

450 < HV0.05 < 750 Ø 25X10 mm 0,1 kg

HV0.1 175 < HV0.1 < 350 Ø 25X10 mm 0,1 kg

350 < HV0.1 < 450 Ø 25X10 mm 0,1 kg

450 < HV0.1 < 750 Ø 25X10 mm 0,1 kg

HV0.2 175 < HV0.2 < 350 Ø 25X10 mm 0,1 kg

350 < HV0.2 < 450 Ø 25X10 mm 0,1 kg

450 < HV0.2 < 750 Ø 25X10 mm 0,1 kg

HV0.3 175 < HV0.3 < 350 Ø 25X10 mm 0,1 kg

350 < HV0.3 < 450 Ø 25X10 mm 0,1 kg

450 < HV0.3 < 750 Ø 25X10 mm 0,1 kg

HV0.5 175 < HV0.5 < 350 Ø 25X10 mm 0,1 kg

350 < HV0.5 < 450 Ø 25X10 mm 0,1 kg

450 < HV0.5 < 750 Ø 25X10 mm 0,1 kg

HV1 175 < HV1< 350 Ø 25X10 mm 0,1 kg

350 < HV1 < 450 Ø 25X10 mm 0,1 kg

450 < HV1 < 750 Ø 25X10 mm 0,1 kg