Rockwel ATI

Metal Testing > Hardness Testers > ATI Benchtop

ROCKWELL HARDNESS TESTERS FOR ALL MATERIALS AND APPLICATIONS

Discover Rockwell hardness testers designed for precision and reliability. Our machines are optimized for Rockwell and Superficial Rockwell scales, offering robust solutions for industries requiring accurate and efficient hardness testing.

Materials Tested with Rockwell Hardness Testers:

- Metals and Alloys: Steel (e.g., hardened steel, stainless steel, carbon steel), aluminum and aluminum alloys, copper, brass, titanium, cast iron.

- Plastics and Polymers: Thermoplastics, rubber components, polymer composites.

- Specialized Materials: Coated surfaces, heat-treated parts, and composites.

Parts Suitable for Rockwell Hardness Testing:

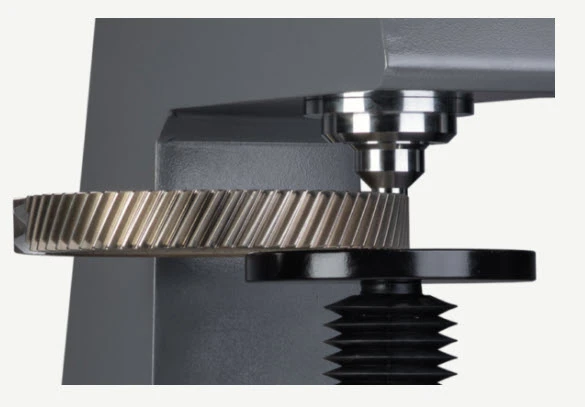

- Industrial and Engine Components: Crankshafts, gears, pistons, bearings, valve seats, and springs.

- Fasteners and Joints: Bolts, nuts, screws, rivets, welds, and brazed joints.

- Tooling and Cutting Instruments: Dies, molds, punches, and cutting tools.

- Automotive and Aerospace Components: Brake rotors, landing gear, suspension parts, and body panels.

- Consumer and Structural Goods: Bicycle frames, sports equipment, and construction materials like rebar and structural steel.

Why Choose Rockwell Hardness Testing?

Rockwell testing is ideal for high-speed, repeatable measurements in production and laboratory settings. It supports a wide range of materials and provides instant readings, making it a cornerstone of material quality assurance.

Key Features of Our Rockwell Hardness Testers:

- Designed for both production environments and lab use, ensuring long-lasting performance.

- Intuitive software for ease of operation, delivering accurate and repeatable results.

- Available in manual, semi-automatic, and fully automatic models to suit diverse applications.

Rockwell Hardness Tester Price: Affordable Solutions for Every Need

When considering a Rockwell hardness tester, price is an important factor, and we offer a range of options to suit every budget and application. Whether you need a cost-effective solution for occasional testing or a high-performance, fully automated tester for demanding industrial environments, we have the right product for you. Our competitive pricing ensures you receive the best value without compromising on quality, accuracy, or reliability. Contact us today to request a quote and discover the perfect Rockwell hardness tester for your needs!

Our Rockwell hardness testers ensure unmatched performance and precision.

Contact us today to learn more and find the right Rockwell testing solution for your needs!

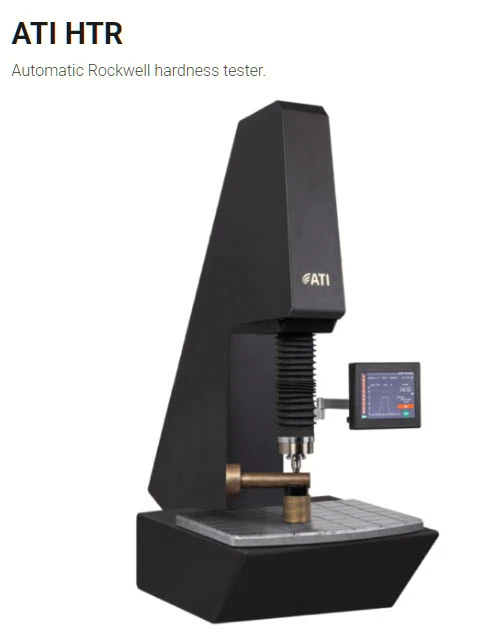

ATI HTR is a fully automatic advanced Rockwell hardness tester designed to accurately measure the hardness of ferrous, non-ferrous metals, and non-metal materials.

Test force closed-loop control system ensures precise automatic tracking and testing, eliminating any poten- tial errors caused by deformation of the frame or workpiece.

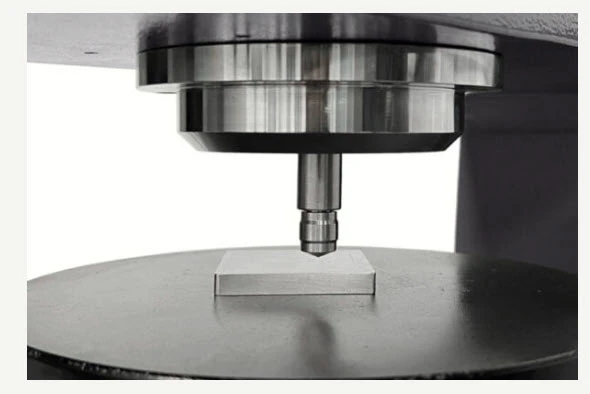

The measuring head offers automatic vertical movement, allowing for quick and secure clamping of workpieces without manual application of preliminary test force.

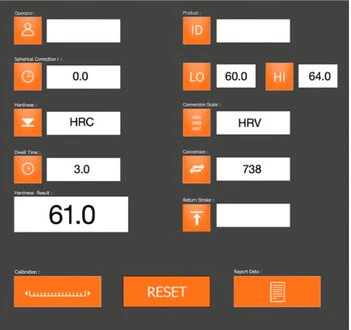

Our advanced test force closed-loop control system ensures precise automatic tracking and testing, eliminating any potential errors caused by deformation of the frame or workpiece. This system is designed to optimize efficiency and accuracy in testing processes, featuring a high-precision optical grating displacement measuring system. The measuring head offers automatic vertical movement, allowing for quick and secure clamping of workpieces without manual application of preliminary test force. This enhances both operator convenience and repeatability in testing procedures, especially when working with irregularly shaped or heavy workpieces. Our equipment includes a large test table, ideal for accommodating workpieces of various shapes and sizes, even those considered abnormal or oversized. The user-friendly large LCD display with menu based operation ensures intuitive navigation through its comprehensive set of functions, such as data processing and hardness conversion across different scales.

Additionally, the system is equipped with a Bluetooth data interface for seamless communication and comes with a printer for immediate result output. For more advanced operations, there is an optional upper computer package that includes specialized software to further enhance data management and analysis. The system’s precision conforms to rigorous international standards, including ISO 6508 , ASTM E18, and GB/T 230.2. This solution is ideal for manufacturers seeking a highly

accurate, fully automated hardness testing system that minimizes human error while maximizing productivity and data accuracy.

Model:ATI HTR

Compliance standards: ISO 6508 , ASTM E18, and GB/T 230.2

Hardness scales: HRA, HRB, HRC, HRD,HRE,HRF, HRG,HRH, HRK, HRL, HRM, HRP, HRR, HRS, HRV, HR15N, HR30N,

HR45N, HR15T, HR30T, HR45T, HR15W, HR30W, HR45W, HR15X, HR30X, HR45X, HR15Y,HR30Y,HR45Y

Measuring range: 20-95HRA,,10-100HRB,,10-70HRC,,70-94HR15N, 42-86HR30N, 20-77HR45N, 67-93HR15TW,

29-82HR30TW, 10-72HR45TW

Pre-load: 29.4 N (3 kgf), 98.1 N (10 kgf)

Total test force: 147.1 N (15 kgf), 294.2 N(30 kgf), 441.3N(45kgf), 588.4N (60kgf), 980.7N (100kgf), 1471N (150kgf)

Resolution: 0.01 HR

Max height of test piece: 170 mm (can be customized,max 350 mm)

Depth capacity of throat: 200 mm

Power supply: 220V / 110V , 50 Hz / 60 Hz

Total dimensions: 669 x 477 x 877 mm – Weight: 130 Kg

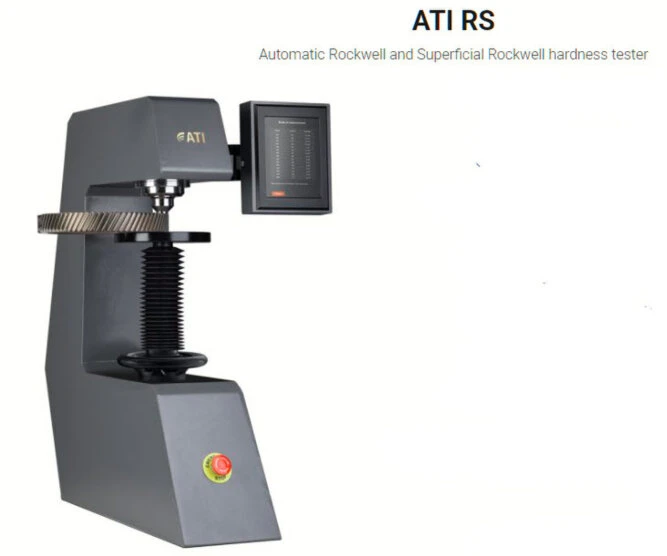

ATI RS Automatic Rockwell and Superficial Rockwell hardness tester

Automatic Rockwell and Superficial Rockwell Hardness Tester, engineered to meet the rigorous standards set forth by ASTM E18, ISO 6508, and ISO 2039-2.

This advanced testing instrument employs a high precision load cell and Closed-Loop electronic control with a 1 KHz sampling rate, ensuring optimal accuracy and reliability.

To begin testing, users simply rotate the handwheel, raising the screw until the standard block makes contact with the indenter, confir- med by the system’s buzzer and “OK” status on the display.

At this point, the initial test force is applied, and the motor automatically initiates the application of the main test force.

Once the dwelling time reaches zero, the system automatically releases the main test force, retaining the initial force for final measurement.

ATI RS is designed to accurately measure the hardness of ferrous, non-ferrous metals, and non-metal materials.

Engineered for high accuracy, this tester meets the needs of manufacturers and engineers who require precise hardness measurements in critical applications.

Model: ATI RS

Compliance standards: ASTM E18, ISO 6508 and ISO 2039-2

Hardness scales: HRA, HRD, HRC, HRF, HRB, HRG, HRH, HRE, HRK, HRL, HRM, HRP, HRR, HRS, HRV, HRN, HRT, HRX,

HRS, ISO 2039-2

Conversion scales: HV, HK, HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRK, HR15N, HR30N, HR45N, HR15T, HR30T,

HR45T, HS,HBW

Initial test force: 3 Kg (29.42 N), 10 Kg (98.07 N)

Total test force: 15 Kg (147.1 N), 30 Kg (294.2 N), 45 Kg (441.3 N), 60 Kg (588.4 N), 100 Kg (980.7 N), 150 Kg (1471 N)

Brinell test force: 62.5 Kg (613N), 125 Kg (1226.2 N), 187.5 Kg (1839.4 N) (at request)

Dwell time: Adjustable from 2 to 60 seconds

Max height of test piece: 230 mm (300mm at request)

Depth capacity of throat: 170 mm

Power supply: 220V / 110V , 50 Hz / 60 Hz

Total dimensions: 475 x 200 x 700 mm

ATI IN

Automatic Rockwell hardness tester with built-in image viewing.

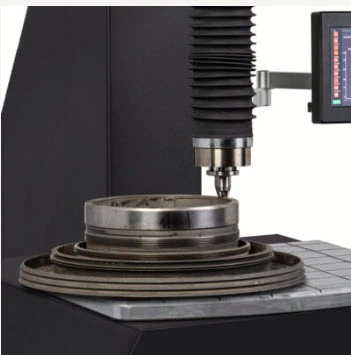

Automatic Rockwell hardness tester with built-in image viewing. ATI IN is represents the ideal solution, the indenter has been specifically designed to reach deep cavities.

This allows you to measure hardness on parts that cannot be measured with a traditional hardness tester.

ATI IN is the solution for hardness tests on components such as rings and tubes (with a minimum internal test diameter of 25 mm) or near flanges or shoulders.

The new structure of the indenter allows a direct view of the test point.

A single START button to start the entire test cycle: when the indenter comes into contact with the surface to be tested, the hardness test phases will begin in automatic succession without interruptions. Preload and load are managed electronically in “Closed-Loop” combined with an electronic load cell system.

Each step of the test cycle appears automatically on the touch screen display built into the body of the hardness tester.

The measurement software is intelligent and easy to use: select the hardness scale, the force value is automatically changed according to the preset test parameters

Model: ATI IN

Compliance standards: ISO 6508, ASTM E18, BSEN 6508, GB/T230

Rockwell initial test force: 3 – 10 kg (29.4 N – 98.07 N)

60 – 100 – 150 kgf (588 – 80 – 1471 N)

Rockwell hardness scale: HRA ,HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, HRL, HRM, HRR, HRP, HRS, HRV

Superficial Rockwell hardness scale: 15N, 15T, 15W, 15X, 15Y, 30N, 30T, 30W, 30X, 30Y, 45N, 45T, 45W, 45W, 45X, 45Y

Rockwell measurement range: HRA: 20 – 88, HRB: 20 – 100, HRC: 20 – 70, HRD: 40 – 77, HRE: 70 – 100, HRF:

60 – 100, HRG: 30 – 94, HRH: 80 – 100, HRK: 40 – 100, HRL: 100 – 120,

HRM: 85 – 115, HRR: 114 – 125

Superficial Rockwell measurement range: HR15N: 70 – 94 , HR30N: 42 – 86 , HR45N: 20 – 77 , HR15T: 67 – 93 ,

HR30T: 29 – 82 , HR45T: 1 – 72

Force control system: Electronic control of load cells in “Closed-Loop”

Dwell time: 1-99 seconds

Hardness resolution: 0.1 HRForce error:<1.0%

Height capacity: 300 mm

Depth capacity: 250 mm

Minimum inner diameter: 25 mm

Power supply: 200V / 200VA , 50~60 Hz >

Total dimensions: 720 x 260 x 840 mm

Total dimensions: 720 x 260 x 840 mm