Rockwel

Metal Testing > Hardness Testers > Benchtop

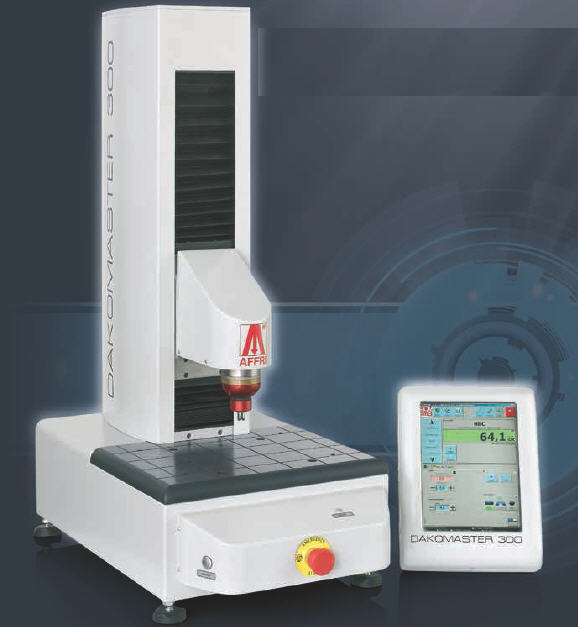

DAKOMASTER 300

Automatic hardness tester for Rockwell, Superficial Rockwell, Brinell, Vickers and Shore test methods in compliance with ASTM and ISO hardness standards. Dakomaster 300 is a top level bench hardness tester with a wide touchscreen allowing easy test planning and a clear view of results. Statistics and diagrams are automatically generated and can be stored with test session in the large archive. User friendly interface with conversion tables and round correction values for tests on convex cylindrical surfaces or various diameters. This hardness tester is fully motorized for fully automatic test cycles, with a long motorized head stroke and a large base. Load forces are applied through load cells and electronically controlled in Closed Loop (Pat. Affri). Hardness testing on all metals: iron, steel, tempered steel, cast iron, brass, aluminum, copper and metal alloys. Heat treatment, hardening, nitriding, cementation and hardfacing. Hard and soft plastics.

Test loads: from 1 to 250 kgf (From 9,807 to 2452 N)

| Standards | EN-ISO 6506-2 / 6507-2 / EN-ISO 6508-2 / EN-ISO 2039 / ISO 868 / ASTM-E18 / ASTM E-10 / ASTM E-384 / ASTM 2240 / JIS |

X-Y Table | 390x295 mm |

| Vertical head stroke | 0/300 mm Motorized |

| Depth capacity | 130 mm |

| Preload | 29.4 - 98.1 N (3 - 10 kgf) |

| Force range | Rockwell: 588.4 - 980.7 - 1471 N (60 - 100 - 150 kgf)

Superficial Rockwell: 29.42 - 147.1 - 294.2 - 441.3 N (3 - 15 - 30 - 45 kgf)

Brinell: 9.807 - 49.03 - 61.29 - 98.07 - 153.2 - 245.2 - 294.2 - 306.5 - 612.9 - 1226 - 1839 N (On request 2452 N)

(1 - 5 - 6.25 - 10 - 15.6 - 25 - 30 - 31.2 - 62.5 - 125 - 187.5 kgf - On request 250 kgf) Vickers - Knoop: 9.807 - 29.42 - 49.03 - 98.07 - 147.1 - 196 - 294.2 - 490.35 - 980.7 N (1 - 3 - 5 - 10 - 15 - 20 - 30 - 50 - 100 kgf)

Optional tests: 49 - 132 - 358 - 961 N (For plastics and rubbers as per EN-ISO 2039 std) |

| Feasible tests | Rockwell: HRA - HRB - HRC - HRD - HRE - HRF - HRG - HRH - HRK - HRL - HRM - HRP - HRR - HRS - HRV

Superficial Rockwell: HR15N - HR30N - HR45N - HR15T - HR30T - HR45T - HR15W - HR30W - HR45W - HR15X - HR30X HR45X - HR15Y - HR30Y - HR45Y

Brinell HBWT: HB1/10 - HB1/30- HB2.5/6.25 - HB2.5/15.625 - HB2.5/31.25 - HB2.5/62.5 - HB2.5/187.5 - HB5/25 - HB5/125 - HB5/250

Vickers (Only indentation): HV1 - HV3 - HV5 - HV10 - HV15 - HV20 - HV30 - HV50 - HV100 |

| Accuracy | Better than 0,2 % |

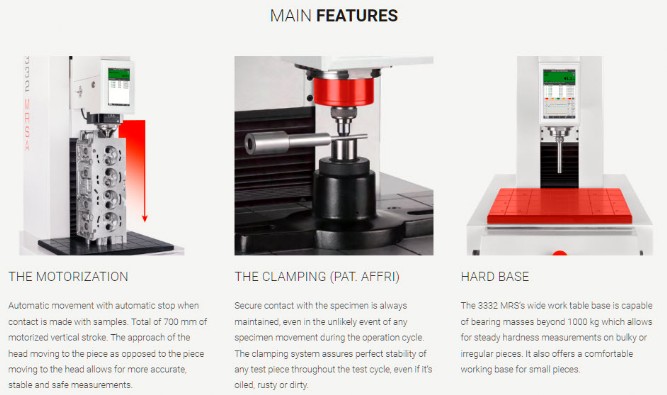

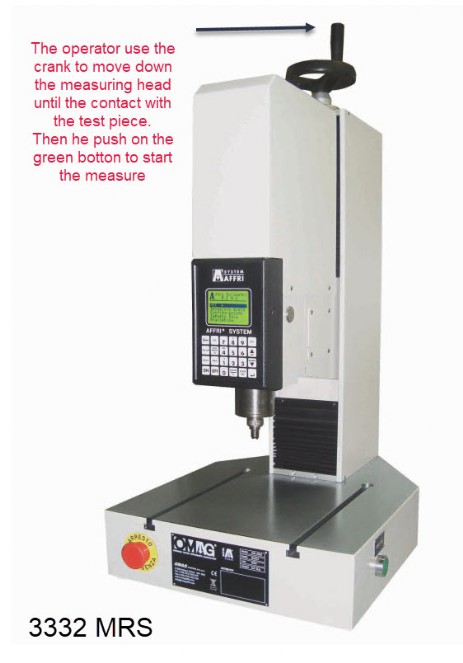

MRS SERIES

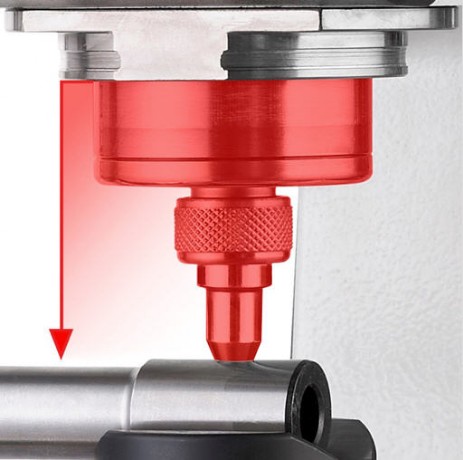

Automatic hardness testers for Rockwell, Superficial Rockwell, Brinell, Vickers and Shore test methods in compliance with ASTM and ISO hardness standards. MRS Series are top level bench hardness testers for tough or lab applications. Fully motorized for fully automatic test cycles. Absolute accuracy (better than 0.5 %) in every condition. Load forces are applied through load cells and electronically controlled in Closed Loop (Pat. Affri). Exact hardness result on the first test and R&R data at the top of his class. Digital durometers with LCD screen, user friendly interface, real time statistics, graphs and large archive storage. Hardness testing on all metals: iron, steel, tempered steel, cast iron, brass, aluminum, copper and metal alloys. Heat treatment, hardening, nitriding, cementation and hardfacing. Hard and soft plastics.

Test loads: from 1 to 250 kgf (From 9,807 to 2452 N)

250 MRS | 3332 MRS | 3332 MRSA | 3302 MRSA | |

Standards | EN-ISO 6506-2 / EN-ISO 6507-2 / EN-ISO 6508-2 / EN-ISO 2039 / EN-ISO 868 / ASTM E-18 E-10 / ASTM E-384 / ASTM E-2240 / JIS | |||

X-Y Table | 330x390 mm | |||

Indenter and clamping-hood stroke | 0/50 mm | ---- | 0/50 mm | |

Vertical head stroke | 0/215 mm | 0/380 mm | 0/500 mm motorized (On request 0/700 mm) | |

Depth capacity | 190 mm | 200 mm | ||

X-Y Table | none | 330 x 390 mm | ||

Tolerable Weight 2000 kg | 2000 kg | 2000 kg | ||

Principle of Operation | Load Cell and Closed Loop | |||

Preload | 29.4 - 98.1 N (3 - 10 kgf) | |||

Force range | Rockwell: 588.4 - 980.7 - 1471 N (60 - 100 - 150 kgf) Superficial Rockwell: 29.42 - 147.1 - 294.2 - 441.3 N (3 - 15 - 30 - 45 kgf) Brinell: 49.03 - 61.29 - 98.07 - 153.2 - 245.2 - 294.2 - 306.5 - 612.9 - 1226 - 1839 N (On request 2452 N) (5 - 6.25 - 10 - 15.6 - 25 - 30 - 31.2 - 62.5 - 125 - 187.5 kgf - On request 250 kgf) Vickers - Knoop: 9.807 - 29.42 - 49.03 - 98.07 - 147.1 - 196 - 294.2 - 490.35 - 980.7 N (1 - 3 - 5 - 10 - 15 - 20 - 30 - 50 - 100 kgf) Optional tests: 49 - 132 - 358 - 961 N (For plastics and rubbers as per EN-ISO 2039 std) Shore A - D | |||

Feasible tests | Rockwell: HRC - HRA - HRD - HRB - HRF - HRG - HRL - HRM - HRR Superficiale Rockwell: HRN - HRT Brinell HBWT: HB30 - HB10 - HB5 - HB2.5 MPa (F/D2) Vickers - Knoop (Only indentation): HV1 - HV3 - HV5 - HV10 - HV15 - HV20 - HV30 - HV50 - HV100 Shore A - D | |||

Accuracy | Better than 0.2 % | |||

RSD SERIES

Semi-automatic hardness testers for Rockwell, Superficial Rockwell, Brinell and Vickers hardness test methods in compliance with ASTM and ISO standards.

RSD Series are bench hardness testers for tough or lab applications.

Rockwell and Brinell HBTW hardness values with absolute accuracy (better than 0.5 %) in every condition, accurate measurements even on the first test will eliminate the need for repeated tests. Load forces are applied through a dynamometric load cell which eliminates problems associated with dead weight systems on traditional testers.

Digital durometers with LCD screen, user friendly interface, real time statistics, graphs and large archive storage. Hardness testing on all metals: iron, steel, tempered steel, cast iron, brass, aluminum, copper and metal alloys. Heat treatment, hardening, nitriding, cementation and hardfacing.

206 RSD / RS-SD | 330 RSD / RS-SD | 903 RSD / RS-SD | |

Standards | EN-ISO 6506-2 / EN-ISO 6507-2 / EN-ISO 6508-2 / ASTM E-18 / ASTM E-10 / ASTM E384/ JIS | ||

X-Y Table | 330x390 mm | ||

Indenter and clamping-hood stroke | 0/50 mm | ||

Vertical head stroke | ---- | 0/300 mm | 0/700 mm (more on request) |

Elevating screw stroke | 0/215 mm | ---- | |

Depth capacity | 190 mm | ||

Preload | RSD: 98,1 N (10 kgf)

RS-SD: 29,4 (3 kgf) | ||

Force range | RSD:

Rockwell: 588.4 - 980.7 - 1471 N (60 - 100 - 150 kgf)

Vickers (Only indentation): 98.07 - 980.7 N (10 - 100 kgf)

Brinell (On request): 98.07 - 612.9 - 1226 - 1839 N - On request 2452 N (10 - 62.5 - 125 - 187.5 kgf - On request 250 kgf)

RS-SD:

Superficial Rockwell: 147.1 - 294.2 - 441.3 N (15 - 30 - 45 kgf)

Vickers (Only indentation): 29.42 - 294.2 N (3 - 30)

Brinell (On request): 153.2 - 294.2 - 306.5 N (15.6 - 30 - 31.2 kgf) | ||

Feasible tests | RSD:

Rockwell: HRC - HRA - HRD - HRB - HRF - HRG - HRL - HRM - HRR

Vickers (Only indentation): HV10 - HV100

Brinell (On request): HB30 - HB10 - HB5 MPa (F/D2)

RS-SD:

Superficial Rockwell: HRN - HRT

Vickers (Only indentation): HV3 - HV30

Brinell (On request): HB30 - HB10 - HB5 MPa (F/D2) | ||

Accuracy | Better than 0.2 % | ||

250 DRM - 206 EX - 206 RT

Semi-automatic hardness testers for Rockwell, Superficial Rockwell,

Brinell and Vickers hardness test methods in compliance with ASTM and

ISO standards. DRM, EX and RT are low cost bench hardness testers with

high accuracy standards.

To perform the test just act on the elevating

screw and bring the sample to make contact with the indenter, pull

lever/ push button and within seconds results appear.

Load forces are

applied through a load cell system which eliminates problems associated

with dead weight systems on traditional testers: not affected by

vibration and no need to be leveled; work in any condition, even

inclined, due to the Affri System where load forces are directly applied

along the indenter's axis, without ratios and levers. Hardness testing

on all metals: iron, steel, tempered steel, cast iron, brass, aluminum,

copper and metal alloys. Heat treatment, hardening, nitriding,

cementation and hardfacing.

250 DRM Hardness tester details

Automatic motorized hardness tester:

250 DRM is a fast and really easy bench hardness testers with high accuracy standards.

250 DRM is a fast and really easy bench hardness testers with high accuracy standards.

To perform the test just act on the elevating screw and bring the sample to make contact with the indenter, then push the start button activating preloading and loading in automatic succession; within seconds results appear.

Load forces are electronically applied throug load cells which eliminates problems associated with dead weight systems on traditional testers.

It is not affected by vibration and it doesn’t need to be leveled.

Main control LCD panel in front of the measuring head for setup of test parameters:

Selection of hardness scales, dwell time, conversion data, return stroke, memory and storage of results, statistics, test temperature measure, calibration, system checkup, tolerance range, in-time results average, correction of round surface and automatic evaluation.

Main control LCD panel in front of the measuring head for setup of test parameters:

Selection of hardness scales, dwell time, conversion data, return stroke, memory and storage of results, statistics, test temperature measure, calibration, system checkup, tolerance range, in-time results average, correction of round surface and automatic evaluation.

206 EX Hardness tester details

Semi-automatic digital hardness tester.

206 EX is a fast and really easy bench hardness testers with high accuracy standards. To perform the test just act on the elevating screw and bring the sample to make contact with the indenter, then pull the lever activating preloading and loading in automatic succession; within seconds results appear. Load forces are applied through two dynamometric load cells which eliminates problems associated with dead weight systems on traditional testers. It is not affected by vibration and it doesn’t need to be leveled.

206 EX is a fast and really easy bench hardness testers with high accuracy standards. To perform the test just act on the elevating screw and bring the sample to make contact with the indenter, then pull the lever activating preloading and loading in automatic succession; within seconds results appear. Load forces are applied through two dynamometric load cells which eliminates problems associated with dead weight systems on traditional testers. It is not affected by vibration and it doesn’t need to be leveled.

206 RT Hardness tester details

Semi-automatic analogic hardness tester:

206RT is a fast and really easy bench hardness testers with high accuracy standards.

To perform the test just act on the elevating screw and bring the sample to make contact with the indenter, then push the start button activating preloading and loading in automatic succession.

Direct Rockwell reading value is immediately visible on the clear dial gauge and can be converted in other hardness scale methods using Affri conversion tables.

Load forces are applied through two dynamometric load cells which eliminates problems associated with dead weight systems on traditional testers.

It is not affected by vibration and it doesn’t need to be leveled.

250 DRM | 206 EX/EXS/EX2 - RT/RTS | |

| Fields of use | Hardness tests on all metals: iron, steel, tempered steel, cast iron, brass, aluminium, copper and metal alloys. Heat treatment, hardening, nitriding, cementation and hardfacing. Hard and soft plastics. | |

Standards | EN-ISO 6506-2 / EN-ISO 6507-2 / EN-ISO 6508-2 / EN-ISO 2039 / ASTM E-18 / ASTM E-10 | EN-ISO 6506-2 / EN-ISO 6507-2 / EN-ISO 6508-2 / ASTM E-18 / ASTM E-10 |

| Elevating screw stroke | 0/215 mm | |

Depth capacity | 190 mm | |

Elevating screw stroke | 0/215 mm | ---- |

Preload | 98,1 N (10 kgf) | EXS/RTS: 29.4 (3 kgf) EX/RT: 98.1 N (10 kgf) |

Force range | Rockwell: 588.4 - 980.7 - 1471 N (60 - 100 - 150 kgf) Superficial Rockwell: 29.42 - 147.1 - 294.2 - 441.3 N (3 - 15 - 30 - 45 kgf) Vickers (Only indentation): 29.42 - 49.03 - 98.07 - 147.1 - 196 - 294.2 - 490.35 - 980.7 N (3 - 5 - 10 - 15 - 20 - 30 - 50 - 100 kgf) Brinell HBWT (Mod. 250 DRMC): 49.03 - 61.29 - 98.07 - 153.2 - 245.2 - 294.2 - 306.5 - 612.9 - 1226 - 1839 N - Optional 2452 N (5 - 6.25 - 10 - 15.6 - 25 - 30 - 31.2 - 62.5 - 125 - 187.5 kgf - Optional 250 kgf) | EX/RT:

Rockwell: 588.4 - 980.7 - 1471 N (60 - 100 - 150 kgf)

Vickers (Only indentation): 98.07 - 980.7 N (10 - 100 kgf)

Brinell HBWT (Optional): 98.07 - 612.9 - 1226 - 1839 N

(10 - 62.5 - 125 - 187.5 kgf) EXS/RTS:

Superficial Rockwell: 147.1 - 294.2 - 441.3 N (15 - 30 - 45 kgf)

Vickers (Only indentation): 29.42 - 294.2 N (3 - 30 kgf)

Brinell HBWT (Optional): 153.2 - 294.2 - 306.5 N (15.625 - 30 - 31.2 kgf)

206EX2:

The hardness tester 206EX2 includes all test loads achievable with versions EX and EXS:

Rockwell: 588.4 - 980.7 - 1471 N (60 - 100 - 150 kgf)

Superficial Rockwell: 147.1 - 294.2 - 441.3 N (15 - 30 - 45 kgf)

Vickers (Only indentation): 98.07 - 29.42 - 294.2 - 980.7 N (3 - 10 - 30 - 100 kgf)

Brinell HBWT (Optional): 98.07 - 153.2 - 294.2 - 306.5 - 612.9 - 1226 - 1839 N (10 - 15.625 - 30 - 31.2 - 62.5 - 125 - 187.5 kgf) |

Feasible tests | Rockwell: HRC - HRA - HRD - HRB - HRF - HRG - HRL - HRM - HRR

Superficial Rockwell: HRN - HRT

Vickers (Only indentation): HV3 - HV5 - HV10 - HV15 - HV 20 - HV30 - HV50 - HV100

Brinell HBWT (Mod. 250 DRMC): HB30 - HB10 - HB5 - HB2.5 MPa (F/D2) | EX/RT:

Rockwell: HRC - HRA - HRD - HRB - HRF - HRG - HRL - HRM - HRR

Brinell HBWT (On request): HB30 - HB10 - HB5 - HB2.5 MPa (F/D2)

(The RT tester doesn't perform Brinell dirct reading) Vickers (Only indentation): HV10 - HV100

EXS/RTS:

Superficial Rockwell: HRN + HRT

Brinell HBWT (On request): HB30 - HB10 - HB5 - HB2,5 MPa (F/D2)

(The RTS tester doesn't perform Brinell dirct reading) Vickers: HV3 - HV30

206EX2:

The hardness tester 206EX2 is able to perform all the feasible tests achievable with versions EX and EXS. |

Accuracy | Better than 0.5 % | |