E SHOP

Pages spéciales

Flow Cup (Ford) 243/III ASTM D 1200 “REFERENCE CLASS”

Viscosity

Ord.-No. : 101- 0060.03.31

Orifice diameter No. 4 (4.1 mm)

Viscosity Range : 31-215 mm²/s Viscosity Range :

Material : anodised aluminium, nozzles of stainless steel

Orifice diameter No. 4 (4.1 mm)

Viscosity Range : 31-215 mm²/s Viscosity Range :

Material : anodised aluminium, nozzles of stainless steel

Flow Cup (Ford) 243/III ASTM D 1200 “REFERENCE CLASS”

Viscosity

Ord.-No. : 101- 0060.02.31

Orifice diameter No. 3 (3.4 mm)

Viscosity Range : 31-215 mm²/s

Material : anodised aluminium, nozzles of stainless steel

Orifice diameter No. 3 (3.4 mm)

Viscosity Range : 31-215 mm²/s

Material : anodised aluminium, nozzles of stainless steel

Flow Cup 243/II technically equivalent to DIN 53 211 without test certificate

Viscosity

Ord.-No. : 101-0064.03.31

Orifice diameter 6 mm

Viscosity Range : 101-

Material : anodised aluminium, nozzles of stainless steel

Orifice diameter 6 mm

Viscosity Range : 101-

Material : anodised aluminium, nozzles of stainless steel

Flow Cup 243/II technically equivalent to DIN 53 211 without test certificate

Viscosity

Ord.-No. : 101- 0064.01.31

Orifice diameter 2 mm

Viscosity Range : 101-

Material : anodised aluminium, nozzles of stainless steel

Orifice diameter 2 mm

Viscosity Range : 101-

Material : anodised aluminium, nozzles of stainless steel

Flow Cup 243/II with official test certificate of the DKD

Viscosity

Ord.-No. : 101- 0249.01.32

Orifice diameter 4 mm

Viscosity Range : 90 - 682 mm²/s

Material : anodised aluminium, nozzles of stainless steel

Orifice diameter 4 mm

Viscosity Range : 90 - 682 mm²/s

Material : anodised aluminium, nozzles of stainless steel

Flow CupDIN 53 211, SIS 184 115, SNV 37 110 “REFERENCE CLASS”

Viscosity

Ord.-No. : 101- 0064.02.31

Orifice diameter 4 mm

Viscosity Range : 90 - 682 mm²/s

Material : anodised aluminium, nozzles of stainless steel

Orifice diameter 4 mm

Viscosity Range : 90 - 682 mm²/s

Material : anodised aluminium, nozzles of stainless steel

2 rolls of adhesive tape for adhesion test according ISO 2409 - 66m x 25mm - 3,50 N/cm

Cross Hatch Cutter 295

Ref : Ref : 215-8705B

For Cross Cut Adhesion Test : adhesive tape sold by 2 rolls. Lenght : 66 m x 25 mm

This tape is used for assessing the adhesion of coating films to metallic substrates by applying and removing pressure-sensitive tape over cuts made in the film.

This adhesive tape having adhesiveness between 6 N per 25 mm width and 10 N per 25 mm width (measured in accordance with IEC 60454-2) must be used to perform the ISO cross cut.

Lenght : 66 m x 25 mm

50 mm widht tape available on request.

Picture only for illustration

For Cross Cut Adhesion Test : adhesive tape sold by 2 rolls. Lenght : 66 m x 25 mm

This tape is used for assessing the adhesion of coating films to metallic substrates by applying and removing pressure-sensitive tape over cuts made in the film.

This adhesive tape having adhesiveness between 6 N per 25 mm width and 10 N per 25 mm width (measured in accordance with IEC 60454-2) must be used to perform the ISO cross cut.

Lenght : 66 m x 25 mm

50 mm widht tape available on request.

Picture only for illustration

2 rolls of adhesive tape for adhesion test according the ASTM D3359-08 - 82m x 25mm - 6.6 N/cm

Cross Hatch Cutter 295

Ref 110-1542ADAST

For Cross Cut Adhesion Test : adhesive tape sold by 2 rolls.

This tape is used for assessing the adhesion of coating films to metallic substrates by applying and removing pressure-sensitive tape over cuts made in the film.

To perform test according astm d3359 : test method A (x-cut)and test method B (a lattice pattern with either six or eleven cuts in each direction) l

This adhesif replace the discontinued Permacel P-99.

For Cross Cut Adhesion Test : adhesive tape sold by 2 rolls.

This tape is used for assessing the adhesion of coating films to metallic substrates by applying and removing pressure-sensitive tape over cuts made in the film.

To perform test according astm d3359 : test method A (x-cut)and test method B (a lattice pattern with either six or eleven cuts in each direction) l

This adhesif replace the discontinued Permacel P-99.

6 rolls of adhesive tape for adhesion test according ISO 2409 - 66 m x 25mm - 3,50 N/cm

Cross Hatch Cutter 295

Ref : 215-8705B6

For Cross Cut Adhesion Test : adhesive tape sold by 6 rolls. Lenght : 66 m x 25 mm

This tape is used for assessing the adhesion of coating films to metallic substrates by applying and removing pressure-sensitive tape over cuts made in the film.

This adhesive tape having adhesiveness between 6 N per 25 mm width

and 10 N per 25 mm width (measured in accordance with IEC 60454-2) must be used to perform the ISO cross cut. Lenght : 66 m x 25 mm

50 mm widht tape available on request.

Picture only for illustration

For Cross Cut Adhesion Test : adhesive tape sold by 6 rolls. Lenght : 66 m x 25 mm

This tape is used for assessing the adhesion of coating films to metallic substrates by applying and removing pressure-sensitive tape over cuts made in the film.

This adhesive tape having adhesiveness between 6 N per 25 mm width

and 10 N per 25 mm width (measured in accordance with IEC 60454-2) must be used to perform the ISO cross cut. Lenght : 66 m x 25 mm

50 mm widht tape available on request.

Picture only for illustration

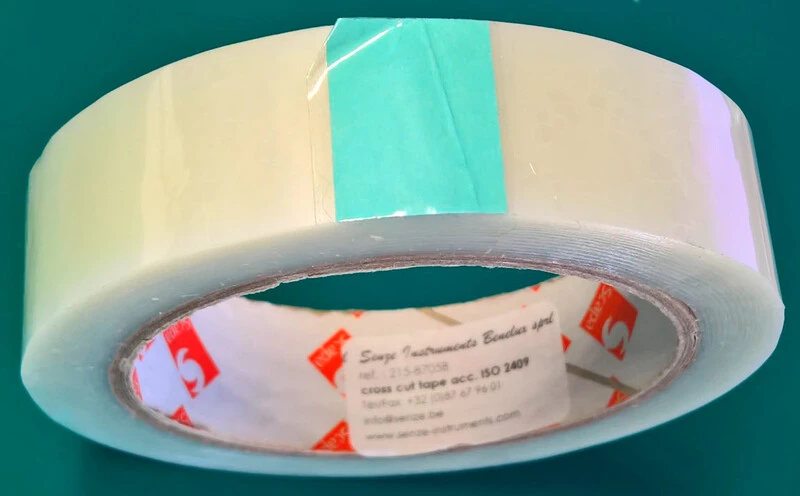

Chucking adapter (rolling) for fixing and vertical guidance of the Hardness Test Pencil

Hadness Test Pencil

Order number: 101-1972.01.32

Cross Scan 295/XVI

Cross Hatch Cutter 295

Order number: 101-03230131

Automatic Cross Hatch Cut Rating System CrossScan 295/XVI

Included in the scope of supply:

Hardware, Software, USB cable and Manual.

Automatic Cross Hatch Cut Rating System CrossScan 295/XVI

Included in the scope of supply:

Hardware, Software, USB cable and Manual.

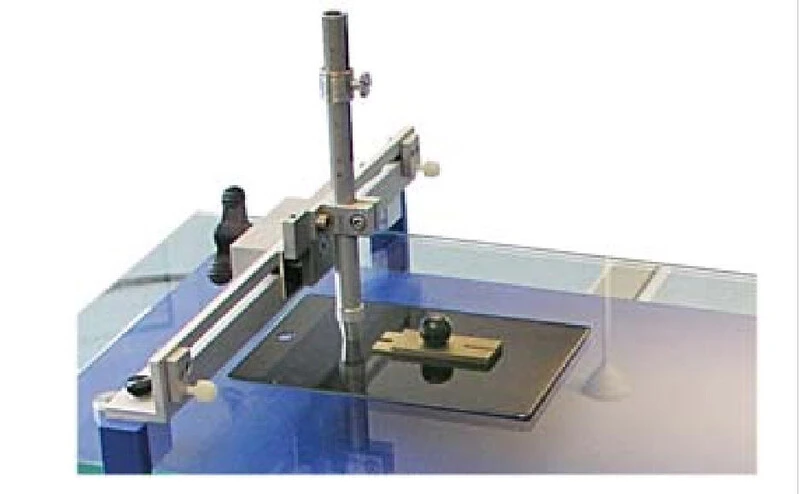

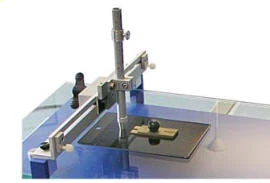

CUPTIMER 243 T with temperature jacket

Viscosity

Ord.-No. : 101-0177.01.31

Flow Time Measuring Instrument CUPTIMER 243 T “REFERENCE CLASS”

Mobile measuring station for exact determination of the flow time (incl. temperature jacket, adapters for ISO, ASTM and DIN flow cups, filling support stand, glass plate, spirit level and plug-in supply unit)

Flow Time Measuring Instrument CUPTIMER 243 T “REFERENCE CLASS”

Mobile measuring station for exact determination of the flow time (incl. temperature jacket, adapters for ISO, ASTM and DIN flow cups, filling support stand, glass plate, spirit level and plug-in supply unit)

CUPTIMER 243 T without temperature jacket

Viscosity

Ord.-No. : 101-0177.02.31

Flow Time Measuring Instrument CUPTIMER 243 T “REFERENCE CLASS” as Ord.-No. 0177.01.31, but without temperature, jacket, filling support stand, glass plate

Flow Time Measuring Instrument CUPTIMER 243 T “REFERENCE CLASS” as Ord.-No. 0177.01.31, but without temperature, jacket, filling support stand, glass plate

Cutter 295/I and holder

Cross Hatch Cutter 295

Order number: 101-0239.01.31

6 edges, cutting distance 1 mm, without Manufacturer’s Test Certificate M

6 edges, cutting distance 1 mm, without Manufacturer’s Test Certificate M

Cutter 295/II and holder

Cross Hatch Cutter 295

Order number: 101-0239.02.31

6 edges, cutting distance 2 mm, without Manufacturer’s Test Certificate M

6 edges, cutting distance 2 mm, without Manufacturer’s Test Certificate M

Cutter 295/V and holder

Cross Hatch Cutter 295

Order number: 101-0239.05.31

11 edges, cutting distance 1 mm, incl. tubular plastic case, without Manufacturer’s Test Certificate M.

11 edges, cutting distance 1 mm, incl. tubular plastic case, without Manufacturer’s Test Certificate M.

Hadness Test Pencil

Order number: 101-02180132

Diamond test tip acc. to DIN EN 438-2 and ISO 4586-2

(with 90 degree included angle and 90 µm radius on the point).

Diamond test tip acc. to DIN EN 438-2 and ISO 4586-2

(with 90 degree included angle and 90 µm radius on the point).

Digital Stop Watch with certificate of the Eichamt (Calibration Office)

Viscosity

Ord.-No. : 101-56 0911241

Dip Flow Cup 322 technically equivalent to DIN ISO 2431

Viscosity

Ord.-No. : 101-0165.04.31

Nozzle Dia. : 6 mm

Viscosity Range : 190 - 680 mm²/s

Material : Aluminium alloy

Nozzle Dia. : 6 mm

Viscosity Range : 190 - 680 mm²/s

Material : Aluminium alloy

Dip Flow Cup 322 technically equivalent to DIN ISO 2431

Viscosity

Ord.-No. : 101-0165.01.31

Nozzle Dia. : 3 mm

Viscosity Range : 10 - 40 mm²/s

Material : Aluminium alloy

Nozzle Dia. : 3 mm

Viscosity Range : 10 - 40 mm²/s

Material : Aluminium alloy

Dip Flow Cup 322 technically equivalent to DIN ISO 2431

Viscosity

Ord.-No. : 101-0165.03.31

Nozzle Dia. : 5 mm

Viscosity Range : 90 - 330 mm²/s

Material : Aluminium alloy

Nozzle Dia. : 5 mm

Viscosity Range : 90 - 330 mm²/s

Material : Aluminium alloy

Dip Flow Cup 322 technically equivalent to DIN ISO 2431

Viscosity

Ord.-No. : 101-0165.02.31

Nozzle Dia. : 4 mm

Viscosity Range : 35 - 135 mm²/s

Material : Aluminium alloy

Nozzle Dia. : 4 mm

Viscosity Range : 35 - 135 mm²/s

Material : Aluminium alloy

Hadness Test Pencil

Orde number: 03340031

ERICHSEN SmartPen with digital test force setting; wit 3 springs and USB-C charging cable in a plastic box

Length (without test head): approx. 18 cm

Weight (without test head): approx. 155 g

ERICHSEN SmartPen with digital test force setting; wit 3 springs and USB-C charging cable in a plastic box

Length (without test head): approx. 18 cm

Weight (without test head): approx. 155 g

Flow Cup (Ford) 243/III ASTM D 1200 “REFERENCE CLASS”

Viscosity

Ord.-No. : 101- 0060.04.31

Orifice diameter No. 5 (5.2 mm)

Viscosity Range : 31-215 mm²/s

Material : anodised aluminium, nozzles of stainless steel

Orifice diameter No. 5 (5.2 mm)

Viscosity Range : 31-215 mm²/s

Material : anodised aluminium, nozzles of stainless steel

Flow Cup (Ford) 243/III ASTM D 1200 “REFERENCE CLASS”

Viscosity

Ord.-No. : 101- 0060.01.31

Orifice diameter No. 2 (2.5 mm)

Viscosity Range : 32-118 mm²/s

Material : anodised aluminium, nozzles of stainless steel

Orifice diameter No. 2 (2.5 mm)

Viscosity Range : 32-118 mm²/s

Material : anodised aluminium, nozzles of stainless steel

Flow Cup (ISO) 243/VII 2 DIN EN ISO 2431 “REFERENCE CLASS”

Viscosity

Ord.-No. : 101-0061.03.31

Nozzle Dia. : 6 mm

Viscosity Range : 188 - 684 mm²/s

Material : anodised aluminium, stainless steel nozzle

Nozzle Dia. : 6 mm

Viscosity Range : 188 - 684 mm²/s

Material : anodised aluminium, stainless steel nozzle

Flow Cup (ISO) 243/VII 2 DIN EN ISO 2431 “REFERENCE CLASS”

Viscosity

Ord.-No. : 101-0061.01.31

Nozzle Dia. : 3 mm

Viscosity Range : 8 - 42 mm²/s

Material : anodised aluminium, stainless steel nozzle

Nozzle Dia. : 3 mm

Viscosity Range : 8 - 42 mm²/s

Material : anodised aluminium, stainless steel nozzle

Flow Cup (ISO) 243/VII 2 DIN EN ISO 2431 “REFERENCE CLASS” with official test certificate of the DKD

Viscosity

Ord.-No. : 101-0250.01.32

Nozzle Dia. : 3 mm

Viscosity Range : 8 - 42 mm²/s

Material : anodised aluminium, stainless steel nozzle

Nozzle Dia. : 3 mm

Viscosity Range : 8 - 42 mm²/s

Material : anodised aluminium, stainless steel nozzle

Flow Cup (ISO) 243/VII 2 DIN EN ISO 2431 “REFERENCE CLASS” with official test certificate of the DKD

Viscosity

Ord.-No. : 101-0250.02.32

Nozzle Dia. : 4 mm

Viscosity Range : 34 - 135 mm²/s

Material : anodised aluminium, stainless steel nozzle

Nozzle Dia. : 4 mm

Viscosity Range : 34 - 135 mm²/s

Material : anodised aluminium, stainless steel nozzle

Flow Cup (ISO) 243/VII 2 DIN EN ISO 2431 “REFERENCE CLASS” with official test certificate of the DKD

Viscosity

Ord.-No. : 101-0250.03.32

Nozzle Dia. : 6 mm

Viscosity Range : 188 - 684 mm²/s

Material : anodised aluminium, stainless steel nozzle

Nozzle Dia. : 6 mm

Viscosity Range : 188 - 684 mm²/s

Material : anodised aluminium, stainless steel nozzle

Flow Cup (ISO) 243/VII 2 DIN EN ISO 2431 “REFERENCE CLASS” with official test certificate of the DKD

Viscosity

Ord.-No. : 101-0250.03.32

Nozzle Dia. : 5 mm

Viscosity Range : 91 - 325 mm²/s

Material : anodised aluminium, stainless steel nozzle

Nozzle Dia. : 5 mm

Viscosity Range : 91 - 325 mm²/s

Material : anodised aluminium, stainless steel nozzle

Flow Cup (ISO) 243/VII 2 DIN EN ISO 2431 “REFERENCE CLASS”

Viscosity

Ord.-No. : 101-0061.04.31

Nozzle Dia. : 5 mm

Viscosity Range : 91 - 325 mm²/s

Material : anodised aluminium, stainless steel nozzle

Nozzle Dia. : 5 mm

Viscosity Range : 91 - 325 mm²/s

Material : anodised aluminium, stainless steel nozzle

Flow Cup (ISO) 243/VII 2 DIN EN ISO 2431 “REFERENCE CLASS”

Viscosity

Ord.-No. : 101-0061.02.31

Nozzle Dia. : 4 mm

Viscosity Range : 34 - 135 mm²/s

Material : anodised aluminium, stainless steel nozzle

Nozzle Dia. : 4 mm

Viscosity Range : 34 - 135 mm²/s

Material : anodised aluminium, stainless steel nozzle

Flow Cup 243/I technically equivalent to DIN 53 211 made of phenol resin, without test certificate

Viscosity

Ord.-No. : 101-0024.05.31

Orifice diameter 3 mm

Viscosity Range : 45 - 300 mm²/s

Material : Phenol resin with stainless steel nozzle

Orifice diameter 3 mm

Viscosity Range : 45 - 300 mm²/s

Material : Phenol resin with stainless steel nozzle

Flow Cup 243/I technically equivalent to DIN 53 211 made of phenol resin, without test certificate

Viscosity

Ord.-No. : 101-0024.02.31

Orifice diameter 4 mm

Viscosity Range : 90 - 682 mm²/s

Material : Phenol resin with stainless steel nozzle

Orifice diameter 4 mm

Viscosity Range : 90 - 682 mm²/s

Material : Phenol resin with stainless steel nozzle

Flow Cup 243/I technically equivalent to DIN 53 211 made of phenol resin, without test certificate

Viscosity

Ord.-No. : 101- 0024.04.31

Orifice diameter 8 mm

Viscosity Range : 500 - 2000 mm²/s

Material : Phenol resin with stainless steel nozzle

Orifice diameter 8 mm

Viscosity Range : 500 - 2000 mm²/s

Material : Phenol resin with stainless steel nozzle

Flow Cup 243/I technically equivalent to DIN 53 211 made of phenol resin, without test certificate

Viscosity

Ord.-No. : 101-0024.03.31

Orifice diameter 6 mm

Viscosity Range : 300 - 1200 mm²/s

Material : Phenol resin with stainless steel nozzle

Orifice diameter 6 mm

Viscosity Range : 300 - 1200 mm²/s

Material : Phenol resin with stainless steel nozzle

Flow Cup 243/I technically equivalent to DIN 53 211made of phenol resin, without test certificate

Viscosity

Ord.-No. : 101-0024.01.31

Orifice diameter 2 mm

Viscosity Range : 22 - 55 mm²/s

Material : Phenol resin with stainless steel nozzle

Orifice diameter 2 mm

Viscosity Range : 22 - 55 mm²/s

Material : Phenol resin with stainless steel nozzle

Flow Cup 243/II technically equivalent to DIN 53 211 without test certificate

Viscosity

Ord.-No. : 101- 0064.04.31

Orifice diameter 8 mm

Viscosity Range : 101-

Material : anodised aluminium, nozzles of stainless steel

Orifice diameter 8 mm

Viscosity Range : 101-

Material : anodised aluminium, nozzles of stainless steel

Flow Cup 243/II technically equivalent to DIN 53 211 without test certificate

Viscosity

Ord.-No. : 101- 0064.05.31

Orifice diameter 3 mm

Viscosity Range : 101-

Material : anodised aluminium, nozzles of stainless steel

Orifice diameter 3 mm

Viscosity Range : 101-

Material : anodised aluminium, nozzles of stainless steel

Folding Ruler (for model 295/III)

Cross Hatch Cutter 295

Order number: 101-0239.07.31

with 10 swivel-mounted folding rulers of 1 mm thickness each as supplied with model 295/III, without Manufacturer's Test Certificate M

with 10 swivel-mounted folding rulers of 1 mm thickness each as supplied with model 295/III, without Manufacturer's Test Certificate M

Folding Ruler (for model 295/XII)

Cross Hatch Cutter 295

order number: 101-0239.08.31

with 10 swivel-mounted folding rulers of 1 mm and 1.5 mm thickness each as supplied with model 295/XII, without Manufacturer's Test Certificate M

with 10 swivel-mounted folding rulers of 1 mm and 1.5 mm thickness each as supplied with model 295/XII, without Manufacturer's Test Certificate M

Folding Ruler with handle

Cross Hatch Cutter 295

Order number: 101-0239.06.31

egonomically optimized, triangular version as supplied with model 295/XIII, with 5 swivel-mounted folding rulers of 1 mm, 2 mm and 3 mm thickness each,

without Manufacturer’s Test Certificate M

egonomically optimized, triangular version as supplied with model 295/XIII, with 5 swivel-mounted folding rulers of 1 mm, 2 mm and 3 mm thickness each,

without Manufacturer’s Test Certificate M

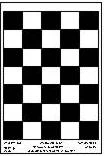

Form 03

Test charts Model 451

Ref. : 101 0049.21.33 used to determine the covering capacity of pigmented paints

for hiding power evaluation

437 x 282 mm

per 125 pcs. Price on request

for hiding power evaluation

437 x 282 mm

per 125 pcs. Price on request

Form 05

Test charts Model 451

Ref. : 101 0049.22.33 used to determine the covering capacity of pigmented paints

for hiding power evaluation

10 H - BW

437 x 282 mm

per 125 pcs. Price on request

for hiding power evaluation

10 H - BW

437 x 282 mm

per 125 pcs. Price on request

Form 09

Test charts Model 451

Ref. : 101 0049.23.33 used to determine the covering capacity of pigmented paints

for hiding power evaluation

14 H - BW

437 x 282 mm

per 125 pcs. Price on request

for hiding power evaluation

14 H - BW

437 x 282 mm

per 125 pcs. Price on request

GAB 12K0.1N

Balance

Readout d 0,1 g

Measuring range Max 12000 g

Min. piece weight at counting 100 mg

Weighing plate (Ø/WxD) 294x225 mm

Stabilisation time s 2 s

Measuring range Max 12000 g

Min. piece weight at counting 100 mg

Weighing plate (Ø/WxD) 294x225 mm

Stabilisation time s 2 s

GAB 30K0.2N

Balance

Readout d 0,0002 kg

Measuring range Max 30 kg

Min. piece weight at counting 200 mg

Weighing plate (Ø/WxD) 294x225 mm

Stabilisation time s 2 s

Measuring range Max 30 kg

Min. piece weight at counting 200 mg

Weighing plate (Ø/WxD) 294x225 mm

Stabilisation time s 2 s

GAB 6K0.05N

Balance

Readout d 0,00005 kg

Measuring range Max 6 kg

Min. piece weight at counting 50 mg

Weighing plate (Ø/WxD) 294x225 mm

Stabilisation time s 2 s

Measuring range Max 6 kg

Min. piece weight at counting 50 mg

Weighing plate (Ø/WxD) 294x225 mm

Stabilisation time s 2 s

Glass plate

Viscosity

Ord.-No. : 101-61 0911941

Handle for the chucking adapter

Hadness Test Pencil

Order number: 101-1969.02.32

Handle for the chucking adapter adaptable anti-slip grip made of aluminium with engraved grid pattern, with freely rotating axis for constant force application. When using Model 318 C, the rotation function has to be locked.

-

Handle for the chucking adapter adaptable anti-slip grip made of aluminium with engraved grid pattern, with freely rotating axis for constant force application. When using Model 318 C, the rotation function has to be locked.

-

Hardness Test Pencil 318

Hadness Test Pencil

Order number: 101-0020.01.31

incl. test tip no. 1 (acc. to Bosch; 0,75 mm Ø) and 3 springs

incl. test tip no. 1 (acc. to Bosch; 0,75 mm Ø) and 3 springs

Hardness Test Pencil 318 S

Hadness Test Pencil

Order number: 101-0273.01.31

with rolling head, incl. test tip no. 1 (acc. to Bosch; 0.75 mm Ø) and 3 springs

with rolling head, incl. test tip no. 1 (acc. to Bosch; 0.75 mm Ø) and 3 springs

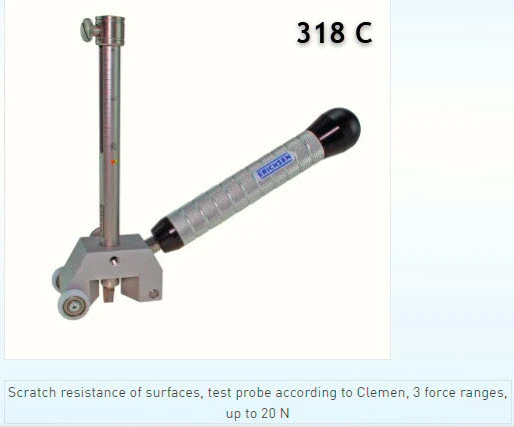

Hardness Test Pencil, Model 318 C (Clemen)

Hadness Test Pencil

Order number: 101-0314.01.31

Hardness Test Pencil, Model 318 C (Clemen) incl. test tip acc. to Clemen (R Ø 1 mm), chucking adapter (rolling – for fixing and vertical guidance of the Hardness Test Pencil), handle (anti-slip grip) and 3 springs

1,294.--

Hardness Test Pencil, Model 318 C (Clemen) incl. test tip acc. to Clemen (R Ø 1 mm), chucking adapter (rolling – for fixing and vertical guidance of the Hardness Test Pencil), handle (anti-slip grip) and 3 springs

1,294.--

Model 321 (DIN Dip Viscosity Cup - technically equivalent to DIN 53 211)

Viscosity

Ord.-No. : 101-0062.03.31

Nozzle Dia. : 6 mm

Viscosity Range : 300 - 1,500 mm²/s

Material : Aluminium alloy

Nozzle Dia. : 6 mm

Viscosity Range : 300 - 1,500 mm²/s

Material : Aluminium alloy

Model 321 (DIN Dip Viscosity Cup - technically equivalent to DIN 53 211)

Viscosity

Ord.-No. : 101-0062.01.31

Nozzle Dia. : 2 mm

Viscosity Range : 10 - 50 mm²/s

Material : Aluminium alloy

Nozzle Dia. : 2 mm

Viscosity Range : 10 - 50 mm²/s

Material : Aluminium alloy

Model 321 (DIN Dip Viscosity Cup - technically equivalent to DIN 53 211)

Viscosity

Ord.-No. : 101-0062.05.31

Nozzle Dia. : 3 mm

Viscosity Range : 30 - 300 mm²/s

Material : Aluminium alloy

Nozzle Dia. : 3 mm

Viscosity Range : 30 - 300 mm²/s

Material : Aluminium alloy

Model 321 (DIN Dip Viscosity Cup - technically equivalent to DIN 53 211)

Viscosity

Ord.-No. : 101-0062.02.31

Nozzle Dia. : 4 mm

Viscosity Range : 50 - 800 mm²/s

Material : Aluminium alloy

Nozzle Dia. : 4 mm

Viscosity Range : 50 - 800 mm²/s

Material : Aluminium alloy

Model 343 (Zahn Dip Viscosity Cup - in accordance with ASTM D 4212)

Viscosity

Ord.-No. : 101-0049.04.32

Nozzle Dia. : No. 4 (0.168")

Viscosity Range : 200 - 1,200 mm²/s

Material : Aluminium alloy

Nozzle Dia. : No. 4 (0.168")

Viscosity Range : 200 - 1,200 mm²/s

Material : Aluminium alloy

Model 343 (Zahn Dip Viscosity Cup - in accordance with ASTM D 4212)

Viscosity

Ord.-No. : 101-0049.03.32

Nozzle Dia. : No. 3 (0.148")

Viscosity Range : 100 - 800 mm²/s

Material : Aluminium alloy

Nozzle Dia. : No. 3 (0.148")

Viscosity Range : 100 - 800 mm²/s

Material : Aluminium alloy

Model 343 (Zahn Dip Viscosity Cup - in accordance with ASTM D 4212)

Viscosity

Ord.-No. : 101-0049.01.32

Nozzle Dia. : No. 1 (0.078")

Viscosity Range : 5 - 60 mm²/s

Material : Aluminium alloy

Nozzle Dia. : No. 1 (0.078")

Viscosity Range : 5 - 60 mm²/s

Material : Aluminium alloy

Model 343 (Zahn Dip Viscosity Cup - in accordance with ASTM D 4212)

Viscosity

Ord.-No. : 101-0049.05.32

Nozzle Dia. : No. 5 (0.207")

Viscosity Range : 400 - 1,800 mm²/s

Material : Aluminium alloy

Nozzle Dia. : No. 5 (0.207")

Viscosity Range : 400 - 1,800 mm²/s

Material : Aluminium alloy

Model 343 (Zahn Dip Viscosity Cup - in accordance with ASTM D 4212)

Viscosity

Ord.-No. : 101-0049.02.32

Nozzle Dia. : No. 2 (0.108")

Viscosity Range : 20 - 250 mm²/s

Material : Aluminium alloy

Nozzle Dia. : No. 2 (0.108")

Viscosity Range : 20 - 250 mm²/s

Material : Aluminium alloy

Multi-Cross Cutter 295/I

Cross Hatch Cutter 295

Order number: 101-0019.01.31

"REFERENCE CLASS"

6 edges, cutting distance 1 mm, incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

6 edges, cutting distance 1 mm, incl. magnifying glass, polyamide bristle brush and plastic case

Multi-Cross Cutter 295/II

Cross Hatch Cutter 295

Order number: 101-0019.02.31

"REFERENCE CLASS"

6 edges, cutting distance 2 mm, incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

6 edges, cutting distance 2 mm, incl. magnifying glass, polyamide bristle brush and plastic case

Multi-Cross Cutter 295/IV

Cross Hatch Cutter 295

Order number: 101-0019.04.31

"REFERENCE CLASS"

2 edges, cutting distance 5 mm, for Grid Cutting Tests acc. to EN (formerly ECCA), incl. magnifying glass, polyamide bristle brush and plastic case, for all coil coatings

"REFERENCE CLASS"

2 edges, cutting distance 5 mm, for Grid Cutting Tests acc. to EN (formerly ECCA), incl. magnifying glass, polyamide bristle brush and plastic case, for all coil coatings

Multi-Cross Cutter 295/IX

Cross Hatch Cutter 295

Order number: 101-0019.09.31

"REFERENCE CLASS"

With free turnable axle between hand grip and cutting head, 6 edges, cutting distance 1 mm,

for Grid Cutting Tests acc. to EN ISO, ISO, VDA and EN, incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

With free turnable axle between hand grip and cutting head, 6 edges, cutting distance 1 mm,

for Grid Cutting Tests acc. to EN ISO, ISO, VDA and EN, incl. magnifying glass, polyamide bristle brush and plastic case

Multi-Cross Cutter 295/V

Cross Hatch Cutter 295

Order number: 101-0019.05.31

"REFERENCE CLASS"

11 edges, cutting distance 1 mm, for Grid Cutting Tests acc. to ASTM and JIS, incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

11 edges, cutting distance 1 mm, for Grid Cutting Tests acc. to ASTM and JIS, incl. magnifying glass, polyamide bristle brush and plastic case

Multi-Cross Cutter 295/VI

Cross Hatch Cutter 295

Order number: 101-0019.06.31

"REFERENCE CLASS"

11 edges, cutting distance 2 mm, for Grid Cutting Tests acc. to ISO, BS and NF, incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

11 edges, cutting distance 2 mm, for Grid Cutting Tests acc. to ISO, BS and NF, incl. magnifying glass, polyamide bristle brush and plastic case

Multi-Cross Cutter 295/VII

Cross Hatch Cutter 295

Order number: 101-0019.07.31

"REFERENCE CLASS"

6 edges, cutting distance 3 mm, for Grid Cutting Tests acc. to EN ISO, ISO, JIS and VDA,

incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

6 edges, cutting distance 3 mm, for Grid Cutting Tests acc. to EN ISO, ISO, JIS and VDA,

incl. magnifying glass, polyamide bristle brush and plastic case

Multi-Cross Cutter 295/X

Cross Hatch Cutter 295

Order number: 101-0019.10.31

"REFERENCE CLASS"

With free turnable axle between hand grip and cutting head, 6 edges, cutting distance 2 mm,

for Grid Cutting Tests acc. to EN ISO, ISO, ASTM, JIS, and VDA, incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

With free turnable axle between hand grip and cutting head, 6 edges, cutting distance 2 mm,

for Grid Cutting Tests acc. to EN ISO, ISO, ASTM, JIS, and VDA, incl. magnifying glass, polyamide bristle brush and plastic case

Multi-Cross Cutter 295/XI

Cross Hatch Cutter 295

Order number: 101-0019.11.31

"REFERENCE CLASS"

With free turnable axle between hand grip and cutting head, 6 edges, cutting distance 3 mm,

for Grid Cutting Tests acc. to EN ISO, ISO, JIS and ASTM, incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

With free turnable axle between hand grip and cutting head, 6 edges, cutting distance 3 mm,

for Grid Cutting Tests acc. to EN ISO, ISO, JIS and ASTM, incl. magnifying glass, polyamide bristle brush and plastic case

PVC foil (Leneta® equivalent)

Test charts Model 451

Ref. : 101 0070.01.32

black, fine matt finish

430 x 165 mm

per 100 pcs. Price on request.

Water-resistant, for wash- and scrubability testing

black, fine matt finish

430 x 165 mm

per 100 pcs. Price on request.

Water-resistant, for wash- and scrubability testing

PVC-Folie (System Leneta®)

Test charts Model 451

Ref. : 101 0070.02.32

black, fine matt finish

430 x 280 mm

per 100 pcs. price on request

Water-resistant, for wash- and scrubability testing

black, fine matt finish

430 x 280 mm

per 100 pcs. price on request

Water-resistant, for wash- and scrubability testing

Hadness Test Pencil

Order numbe : 101-19720332

Hadness Test Pencil

Rolling test head „318 S“ usable with:

- test tips no. 1 up to no. 4 and

- test tip for writing inclination test acc. to BMW

- test tips no. 1 up to no. 4 and

- test tip for writing inclination test acc. to BMW

Hadness Test Pencil

Order number: 101-30120232

Rolling test head „435 S“ for using a test tool made of Steel

Rolling test head „435 S“ for using a test tool made of Steel

Hadness Test Pencil

Order number: 101-30120132

Rolling test head „435“ for using test discs made of Duroplast, Copper and Stainless Steel

Rolling test head „435“ for using test discs made of Duroplast, Copper and Stainless Steel

SCROLLRULER 295/XV

Cross Hatch Cutter 295

Order number: 101-0019.15.31

Universal cross cut ruler, scaled cutting distances

(6 x 1 mm, 6 x 2 mm, 6 x 3 mm, 11 x 1 and 11 x 1,5 mm) adjusted by turning a thumb wheel

Universal cross cut ruler, scaled cutting distances

(6 x 1 mm, 6 x 2 mm, 6 x 3 mm, 11 x 1 and 11 x 1,5 mm) adjusted by turning a thumb wheel

Single Edge Cutting Device 295/XIV

Cross Hatch Cutter 295

Order number: 101-0019.14.31

hard-coated test tip mounted into an adapter block with holder, for cuts on curved

surfaces, incl. flexible ruler and plastic case, without Manufacturer’s Test Certificate M

hard-coated test tip mounted into an adapter block with holder, for cuts on curved

surfaces, incl. flexible ruler and plastic case, without Manufacturer’s Test Certificate M

Single Edge Cutting Device with Folding Ruler 295/III)

Cross Hatch Cutter 295

Order number: 101-0019.03.31

"REFERENCE CLASS"

With 10 swivel-mounted folding ruler of 1 mm thickness each, for Grid Cutting Tests acc. to EN ISO, ISO, ASTM, JIS, BS, NF, SNV, EN and VDA, incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

With 10 swivel-mounted folding ruler of 1 mm thickness each, for Grid Cutting Tests acc. to EN ISO, ISO, ASTM, JIS, BS, NF, SNV, EN and VDA, incl. magnifying glass, polyamide bristle brush and plastic case

Single Edge Cutting Device with Folding Ruler 295/XII

Cross Hatch Cutter 295

Order number: 101-0019.12.31

"REFERENCE CLASS"

With 10 swivel-mounted folding rulers of 1 mm and 1.5 mm thickness each, for Grid Cutting Tests acc. to EN ISO, ISO, ASTM, JIS, BS, NF, SNV, EN, VDA and Daimler Benz (1.5 mm), incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

With 10 swivel-mounted folding rulers of 1 mm and 1.5 mm thickness each, for Grid Cutting Tests acc. to EN ISO, ISO, ASTM, JIS, BS, NF, SNV, EN, VDA and Daimler Benz (1.5 mm), incl. magnifying glass, polyamide bristle brush and plastic case

Single Edge Cutting Device with Folding Ruler 295/XIII

Cross Hatch Cutter 295

Order number: 101-0019.13.31

"REFERENCE CLASS"

Ergonomical optimized, triangular version with handle and 5 swivel-mounted folding rulers of 1 mm, 2 mm and 3 mm thickness each, for Grid Cutting Tests acc. to EN ISO, ISO, ASTM, JIS, BS, NF, SNV, EN and VDA, incl. magnifying glass, polyamide bristle brush and plastic case

"REFERENCE CLASS"

Ergonomical optimized, triangular version with handle and 5 swivel-mounted folding rulers of 1 mm, 2 mm and 3 mm thickness each, for Grid Cutting Tests acc. to EN ISO, ISO, ASTM, JIS, BS, NF, SNV, EN and VDA, incl. magnifying glass, polyamide bristle brush and plastic case

Size A4

Test charts Model 451

Ref. : 101 0049.19.33

white, no contrast pattern, for comparison of tone and tint

(210 x 297 mm) 500 cm²

per 100 pcs.

white, no contrast pattern, for comparison of tone and tint

(210 x 297 mm) 500 cm²

per 100 pcs.

Size A5

Test charts Model 451

Ref. : 101 0049.14.33

white, no contrast pattern, for comparison of tone and tint

(148 x 210 mm) 250 cm²

per 100 pcs. price on request

white, no contrast pattern, for comparison of tone and tint

(148 x 210 mm) 250 cm²

per 100 pcs. price on request

Size A6

Test charts Model 451

Ref. : 101 0049.10.33

white, no contrast pattern, for comparison of tone and tint

(105 x 148 mm) 125 cm²

per 100 pcs. Price on request.

white, no contrast pattern, for comparison of tone and tint

(105 x 148 mm) 125 cm²

per 100 pcs. Price on request.

Special head for use Model 318 in connection with film applicator COATMASTER 510 MC

Hadness Test Pencil

Order number: 101-0708.01.32

Special head (for use Model 318 in connection with film applicator COATMASTER 510)

Hadness Test Pencil

Order number: 101-0769.01.32

Special support stand with spirit level

Viscosity

Ord.-No. : 101-0478.01.32

Spring 0 - 10 N

Hadness Test Pencil

Order number: 101-0429.02.32

Spring 0 - 10 N red marked

Spring 0 - 10 N red marked

Spring 0 - 20 N

Hadness Test Pencil

Order number: 101-0429.03.32

Spring 0 - 20 N yellow marked

Spring 0 - 20 N yellow marked

Spring 0 - 3 N

Hadness Test Pencil

Order number: 101-0429.01.32

Spring 0 - 3 N blue marked

Spring 0 - 3 N blue marked

Temperature jacket with adapters for ISO, ASTM and DIN flow cups

Viscosity

Ord.-No. : 101-0483.01.32

Hadness Test Pencil

Order number: 101-04300231

Test disc made of Copper

Test disc made of Copper

Hadness Test Pencil

Order number: 101-04300132

Test disc made of Duroplast

Test disc made of Duroplast

Hadness Test Pencil

Order number: 101-04300332

Test disc made of Stainless Steel

Test disc made of Stainless Steel

Test head „C“ (movable/retrofit) for models 318/318 S, for using the Clemen test tip

Hadness Test Pencil

Order number: 101-2109.01.32

Attention: Requires a Clemen test tip as well as a chucking adapter (rolling – for fixing and vertical guidance of the Hardness Test Pencil) and handle (anti-slip grip)

Attention: Requires a Clemen test tip as well as a chucking adapter (rolling – for fixing and vertical guidance of the Hardness Test Pencil) and handle (anti-slip grip)

Hadness Test Pencil

Order number: 101-30070132

Test head „318“ for using test tips no. 1 up to no. 4 and test tip for writing

inclination test acc. to BMW

Test head „318“ for using test tips no. 1 up to no. 4 and test tip for writing

inclination test acc. to BMW

Test tip (Ø 3 mm) for scratch inclination test acc. to BMW GS 97034-8

Hadness Test Pencil

Order number: 101-0428.05.32

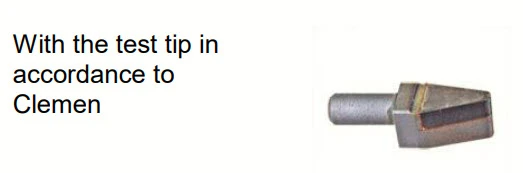

Test tip acc. to Clemen (R 1.0 mm)

Hadness Test Pencil

Order number: 101-0218.02.32

Hadness Test Pencil

Order number: 101-05640132

Test tip for cross hatch cutting (30°) additionally covered with an extremly hard layer

(short shaft with flat clamping area)

Test tip for cross hatch cutting (30°) additionally covered with an extremly hard layer

(short shaft with flat clamping area)

Test tip no. 1

Hadness Test Pencil

Order number: 101-0428.02.32

Test tip no. 1 (acc. to Bosch (Ø 0,75 mm) for scratch test acc. to BMW GS 97034-9)

Test tip no. 1 (acc. to Bosch (Ø 0,75 mm) for scratch test acc. to BMW GS 97034-9)

Test tip no. 2

Hadness Test Pencil

Order number: 101-0428.03.32

Test tip no. 2 (acc. to ISO 1518 and GME 60280 (Ø 1.0 mm)

Test tip no. 2 (acc. to ISO 1518 and GME 60280 (Ø 1.0 mm)

Test tip no. 3

Hadness Test Pencil

Order number: 101-0428.04.32

Test tip no. 3 (acc. to van Laar; 0.5 mm Ø)

Test tip no. 3 (acc. to van Laar; 0.5 mm Ø)

Test tip no. 4

Hadness Test Pencil

Order number: 101-0428.01.32

Test tip no. 4 (acc. to Opel; 0.5 mm Ø)

Test tip no. 4 (acc. to Opel; 0.5 mm Ø)

Hadness Test Pencil

Order number: 101-07960132

Test tool made of Steel

Test tool made of Steel

Thermometer acc. to DIN 12 755

Viscosity

Ord.-No. : 101-57 0911341

T° scale from 0 to 50°C

Reading accuracy 0.2°C,

Suitable for all models 243/I to 243/VII

T° scale from 0 to 50°C

Reading accuracy 0.2°C,

Suitable for all models 243/I to 243/VII

Typ "as RGF 2" (black/grey)

Test charts Model 451

Ref. : 101 0049.04.33

with contrast pattern for hiding power comparison

black/grey

280 x 50 mm

per 100 pcs. Price on request.

with contrast pattern for hiding power comparison

black/grey

280 x 50 mm

per 100 pcs. Price on request.

Typ "RGF 2" (red/grey)

Test charts Model 451

Ref. : 101 0049.03.33

with contrast pattern for hiding power comparison

red/grey

280 x 50 mm

per 100 pcs. Price on request.

with contrast pattern for hiding power comparison

red/grey

280 x 50 mm

per 100 pcs. Price on request.

Typ 107 D

Test charts Model 451

Ref. : 101 0049.02.33

plain white, for contrast comparison

185 x 105 mm

per 100 pcs.

plain white, for contrast comparison

185 x 105 mm

per 100 pcs.

Typ 108 D

Test charts Model 451

Ref. : 101 0049.01.33

with contrast pattern for hiding power comparison

185 x 105 mm

per 100 pcs.

with contrast pattern for hiding power comparison

185 x 105 mm

per 100 pcs.

Typ 22/4

Test charts Model 451

Ref. : 101 0049.17.33

Test charts to determine the hiding power and contrast ratio of pigmented systems in organic solvents.

Test Area: 500 cm²

per 100 pcs. Price on request.

Test charts to determine the hiding power and contrast ratio of pigmented systems in organic solvents.

Test Area: 500 cm²

per 100 pcs. Price on request.

Typ 22/4U

Test charts Model 451

Ref. : 101 0049.18.33

Test charts to determine the hiding power and contrast ratio of pigmented systems in organic solvents.

The Penetration Hiding Power Charts 22/4U to determine the penetration properties and hiding power of water thinnable paints (colour dispersion). The unlacquered surfaces guarantee an optimum of wetting properties.

Test Area: 500 cm²

per 100 pcs. Price on request.

Test charts to determine the hiding power and contrast ratio of pigmented systems in organic solvents.

The Penetration Hiding Power Charts 22/4U to determine the penetration properties and hiding power of water thinnable paints (colour dispersion). The unlacquered surfaces guarantee an optimum of wetting properties.

Test Area: 500 cm²

per 100 pcs. Price on request.

Typ 22/5

Test charts Model 451

Ref. : 101 0049.15.33

Test charts to determine the hiding power and contrast ratio of pigmented systems in organic solvents.

Test Area: 250 cm²

per 100 pcs. Price on request.

Test charts to determine the hiding power and contrast ratio of pigmented systems in organic solvents.

Test Area: 250 cm²

per 100 pcs. Price on request.

Typ 23/5

Test charts Model 451

Ref. : 101 0049.11.33

Test charts to determine the hiding power and contrast ratio of pigmented systems in organic solvents.

Test Area: 250 cm²

per 100 pcs. Price on request.

Test charts to determine the hiding power and contrast ratio of pigmented systems in organic solvents.

Test Area: 250 cm²

per 100 pcs. Price on request.

Typ 24/5

Test charts Model 451

Ref. : 101 0049.09.33

Test charts to determine the hiding power and contrast ratio of pigmented systems in organic solvents.

Test Area: 250 cm²

per 100 pcs. Price on request.

Test charts to determine the hiding power and contrast ratio of pigmented systems in organic solvents.

Test Area: 250 cm²

per 100 pcs. Price on request.

Typ 24/6

Test charts Model 451

Ref. : 101 0049.06.33

Test charts to determine the hiding power and contrast ratio of pigmented systems in organic solvents.

Test Area: 125 cm²

per 100 pcs. Price on request.

Test charts to determine the hiding power and contrast ratio of pigmented systems in organic solvents.

Test Area: 125 cm²

per 100 pcs. Price on request.

Typ 7.32/7

Test charts Model 451

Ref. : 101 0049.08.33

with contrast pattern for hiding power comparison

185 x 75 mm

per 100 pcs. Price on request.

with contrast pattern for hiding power comparison

185 x 75 mm

per 100 pcs. Price on request.

Typ 7.32/U

Test charts Model 451

Ref. : 101 0049.07.33

with contrast pattern for hiding power comparison

185 x 75 mm

per 100 pcs. Price on request.

with contrast pattern for hiding power comparison

185 x 75 mm

per 100 pcs. Price on request.

Typ 73 D

Test charts Model 451

Ref. : 101 0049.13.33

plain white, for contrast comparison

185 x 75 mm

per 100 pcs. Price on request.

plain white, for contrast comparison

185 x 75 mm

per 100 pcs. Price on request.

Typ 74 D

Test charts Model 451

Ref. : 101 0049.12.33

with contrast pattern for hiding power comparison

185 x 75 mm

per 100 pcs. Price on request.

with contrast pattern for hiding power comparison

185 x 75 mm

per 100 pcs. Price on request.

Typ ASTM D 7488

Test charts Model 451

Test chart black according to ASTM D 7488

Ref. 236-62781225

400 x 120 mm

Per 250 pces Price on request.

Ref. 236-62781225

400 x 120 mm

Per 250 pces Price on request.

Visco Test Blade Model 301 acc. to Rossmann

Viscosity

Ord.-No. : 101-0021.02.31

Simple consistency test.

The Visco Test Blade is designed for the rapid determination of the viscosity of paints for spray and brush application. On the one hand it is a practical stirring utensil when adding thinner to the paint and, on the other hand, it serves as a device to measure the viscosity of the substance. It is easy to use and to clean, making it a convenient instrument for use in the practice.

The Visco Test Blade is immersed into the test liquid in such a way that the slit is entirely covered, whilst the upper hole remains free. The blade is then lifted quickly out of the liquid, holding it upright, and the time measured until the fluid meniscus in the slit reaches the lower hole. This point is clearly visible since the membrane covering the hole will burst at that moment. The run-off speed in the slit is also influenced by the run-off speed on the remainder of the blade. The immersion depth should therefore be adhered to exactly. Properly wetted the blade prior to the test.

Simple consistency test.

The Visco Test Blade is designed for the rapid determination of the viscosity of paints for spray and brush application. On the one hand it is a practical stirring utensil when adding thinner to the paint and, on the other hand, it serves as a device to measure the viscosity of the substance. It is easy to use and to clean, making it a convenient instrument for use in the practice.

The Visco Test Blade is immersed into the test liquid in such a way that the slit is entirely covered, whilst the upper hole remains free. The blade is then lifted quickly out of the liquid, holding it upright, and the time measured until the fluid meniscus in the slit reaches the lower hole. This point is clearly visible since the membrane covering the hole will burst at that moment. The run-off speed in the slit is also influenced by the run-off speed on the remainder of the blade. The immersion depth should therefore be adhered to exactly. Properly wetted the blade prior to the test.

Viscosity Nomogramme and Viscosity Temperature Comparative Dial Ericshen 458

Viscosity

Ord.-No. : 101-0099.01.31

The Nomogram Disk 458 is designed for the conversion of viscosity measurement data in various unitary systems which have a specified reference temperature within any one unitary system.

• The VISCOSITY NOMOGRAM makes it possible to convert viscosity data into the following units reference temperatures between 15°C and 25°C):

• cSt = mm²s-¹

• cP = mPa s

• Engler degrees

• Krebs Stormer units

• Gardner Holdt units

• Efflux times

- ISO 2431 (4 mm)

- ASTM D 1200 (Ford No. 3, No. 4)

- DIN 53 211

The TEMPERATURE-DEPENDENT VISCOSITY SCALE is used for converting viscosity data for reference temperatures in the range between 5°C and 30°C.

The Nomogram Disk 458 is designed for the conversion of viscosity measurement data in various unitary systems which have a specified reference temperature within any one unitary system.

• The VISCOSITY NOMOGRAM makes it possible to convert viscosity data into the following units reference temperatures between 15°C and 25°C):

• cSt = mm²s-¹

• cP = mPa s

• Engler degrees

• Krebs Stormer units

• Gardner Holdt units

• Efflux times

- ISO 2431 (4 mm)

- ASTM D 1200 (Ford No. 3, No. 4)

- DIN 53 211

The TEMPERATURE-DEPENDENT VISCOSITY SCALE is used for converting viscosity data for reference temperatures in the range between 5°C and 30°C.

VISCOSOFT® 460-FC

Viscosity

Ord.-No. : 101-0173.01.31

WINDOWS® based software 1 licence (disc)

This software which has been specifically developed to enable rapid conversions between viscosity and efflux times for standardized flow cups.

WINDOWS® based software 1 licence (disc)

This software which has been specifically developed to enable rapid conversions between viscosity and efflux times for standardized flow cups.

Zahn Flow Cup complete set of 5 cups

Viscosity

Ord.-No. :101-0030.01.31

complete with 5 exchangeable cups of orifice diameter No. 1 (0.078"), No. 2 (0.108"), No. 3 (0.148"), No. 4 (0.168") and No. 5 (0.207"), including carrying case

complete with 5 exchangeable cups of orifice diameter No. 1 (0.078"), No. 2 (0.108"), No. 3 (0.148"), No. 4 (0.168") and No. 5 (0.207"), including carrying case